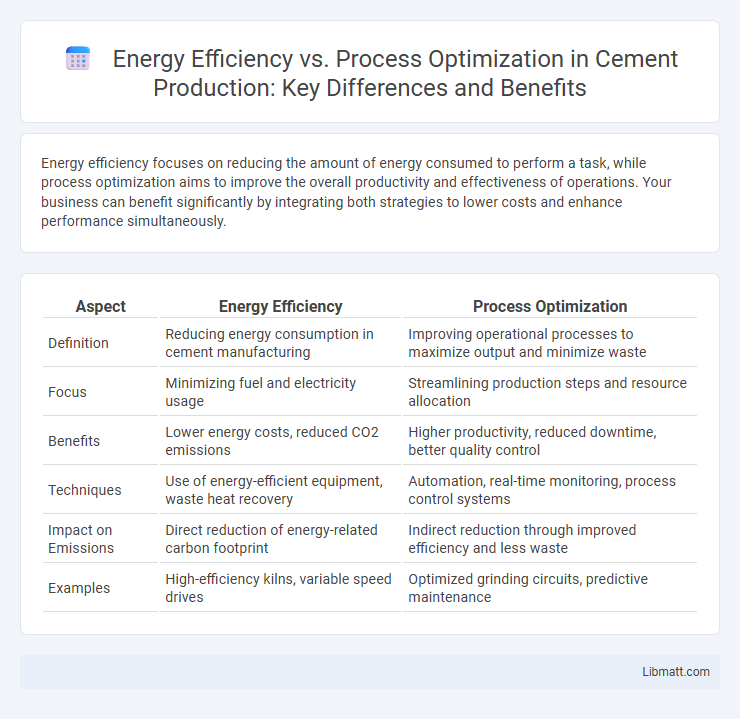

Energy efficiency focuses on reducing the amount of energy consumed to perform a task, while process optimization aims to improve the overall productivity and effectiveness of operations. Your business can benefit significantly by integrating both strategies to lower costs and enhance performance simultaneously.

Table of Comparison

| Aspect | Energy Efficiency | Process Optimization |

|---|---|---|

| Definition | Reducing energy consumption in cement manufacturing | Improving operational processes to maximize output and minimize waste |

| Focus | Minimizing fuel and electricity usage | Streamlining production steps and resource allocation |

| Benefits | Lower energy costs, reduced CO2 emissions | Higher productivity, reduced downtime, better quality control |

| Techniques | Use of energy-efficient equipment, waste heat recovery | Automation, real-time monitoring, process control systems |

| Impact on Emissions | Direct reduction of energy-related carbon footprint | Indirect reduction through improved efficiency and less waste |

| Examples | High-efficiency kilns, variable speed drives | Optimized grinding circuits, predictive maintenance |

Introduction to Energy Efficiency and Process Optimization

Energy efficiency focuses on reducing the amount of energy required to perform a specific task or produce a product, significantly lowering operational costs and environmental impact. Process optimization involves refining workflows and systems to maximize productivity, minimize waste, and improve overall performance in industrial or business operations. Understanding the balance between energy efficiency and process optimization helps you achieve sustainable growth while maintaining high operational standards.

Key Differences Between Energy Efficiency and Process Optimization

Energy efficiency focuses on reducing energy consumption by improving the performance of systems or equipment, targeting lower energy usage without compromising output. Process optimization aims to enhance overall operational workflows, improving productivity, quality, and cost-effectiveness through analyzing and fine-tuning each step of the process. The key difference lies in energy efficiency prioritizing minimal energy waste, while process optimization seeks broader improvements in process performance and resource utilization.

The Role of Energy Efficiency in Modern Industries

Energy efficiency plays a pivotal role in modern industries by significantly reducing operational costs and minimizing environmental impact through optimized energy consumption. Advanced technologies such as smart sensors, automation, and energy management systems enable precise control over energy use, enhancing productivity while conserving resources. Integrating energy efficiency with process optimization drives sustainable industrial growth by balancing energy savings with improved process performance and product quality.

Process Optimization: Definition and Benefits

Process optimization involves analyzing and improving workflows to increase efficiency, reduce costs, and enhance product quality through systematic adjustments. It leverages data-driven techniques and automation to minimize waste, streamline operations, and boost overall productivity in manufacturing or service processes. By implementing process optimization, your organization can achieve sustainable growth and maintain competitive advantage while reducing energy consumption indirectly.

Synergy Between Energy Efficiency and Process Optimization

Energy efficiency and process optimization create a powerful synergy by reducing energy consumption while enhancing operational performance, leading to significant cost savings and sustainability improvements. Integrating advanced control systems and real-time data analytics enables precise monitoring and adjustment of energy use across manufacturing processes. This holistic approach maximizes resource utilization, minimizes waste, and supports compliance with environmental standards.

Measuring Success: KPIs for Energy and Process Optimization

Key performance indicators (KPIs) for energy efficiency focus on metrics such as energy consumption per unit of output, carbon footprint reduction, and cost savings from decreased energy use. Process optimization KPIs measure throughput, cycle time, defect rates, and resource utilization to ensure operational improvements. Tracking these KPIs allows you to evaluate how energy management aligns with overall process performance, driving sustainable and cost-effective production.

Technologies Driving Efficiency and Optimization

Advanced automation systems and AI-driven analytics significantly enhance energy efficiency by dynamically adjusting power usage based on real-time process conditions. IoT sensors collect granular data enabling precise monitoring and control, which not only reduces waste but also supports process optimization through predictive maintenance and operational adjustments. Integration of machine learning algorithms enables continuous process improvement, driving both energy savings and increased production efficiency in industrial environments.

Common Challenges and Barriers

Energy efficiency and process optimization face common challenges such as high initial costs, limited access to advanced technology, and resistance to change within organizations. Data integration difficulties and lack of skilled personnel further hinder effective implementation of energy-saving and process improvement initiatives. Overcoming regulatory complexities and securing continuous management support remain critical barriers to achieving sustained performance gains.

Industry Case Studies: Real-World Applications

Industry case studies reveal that energy efficiency improvements reduce operational costs by up to 30% through optimized energy consumption in manufacturing plants. Process optimization often leads to enhanced production speeds and product quality, demonstrated by companies implementing lean manufacturing techniques that minimize waste and downtime. Your business can leverage these real-world examples to balance energy savings with productivity enhancements, achieving sustainable growth and competitive advantage.

Future Trends in Energy and Process Optimization

Future trends in energy efficiency and process optimization emphasize the integration of AI-driven analytics and IoT technologies to monitor and reduce energy consumption in real-time. Advanced machine learning algorithms enable predictive maintenance and process adjustments, maximizing operational efficiency and minimizing waste. Your investment in these smart solutions ensures sustainable growth and significant energy cost savings across industrial systems.

Energy efficiency vs Process optimization Infographic

libmatt.com

libmatt.com