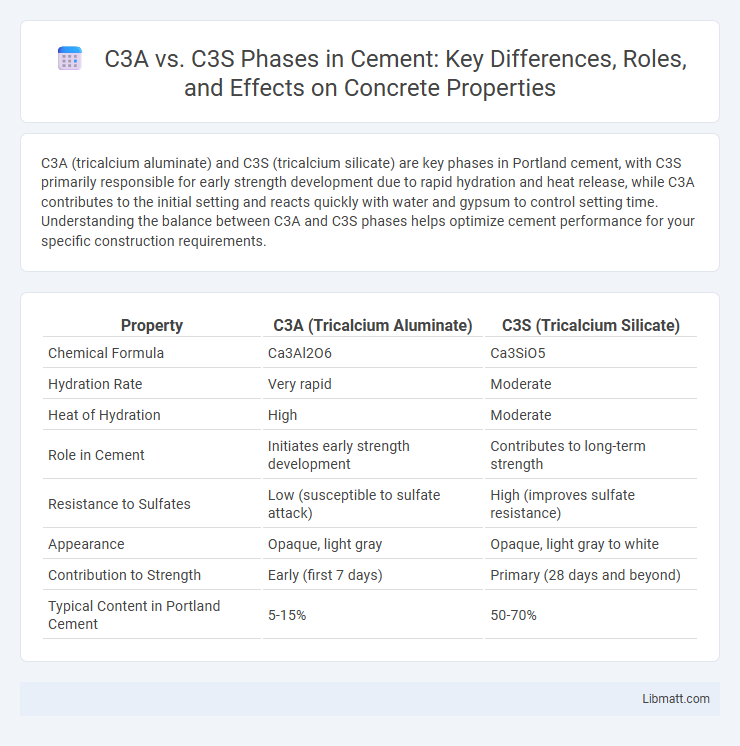

C3A (tricalcium aluminate) and C3S (tricalcium silicate) are key phases in Portland cement, with C3S primarily responsible for early strength development due to rapid hydration and heat release, while C3A contributes to the initial setting and reacts quickly with water and gypsum to control setting time. Understanding the balance between C3A and C3S phases helps optimize cement performance for your specific construction requirements.

Table of Comparison

| Property | C3A (Tricalcium Aluminate) | C3S (Tricalcium Silicate) |

|---|---|---|

| Chemical Formula | Ca3Al2O6 | Ca3SiO5 |

| Hydration Rate | Very rapid | Moderate |

| Heat of Hydration | High | Moderate |

| Role in Cement | Initiates early strength development | Contributes to long-term strength |

| Resistance to Sulfates | Low (susceptible to sulfate attack) | High (improves sulfate resistance) |

| Appearance | Opaque, light gray | Opaque, light gray to white |

| Contribution to Strength | Early (first 7 days) | Primary (28 days and beyond) |

| Typical Content in Portland Cement | 5-15% | 50-70% |

Introduction to C3A and C3S Phases

C3A (tricalcium aluminate) and C3S (tricalcium silicate) are essential phases in Portland cement that influence its hydration and strength development. C3S primarily contributes to early strength gain through rapid hydration, while C3A reacts quickly with water and gypsum to form ettringite, affecting setting time and sulfate resistance. Understanding how these phases interact helps optimize your cement formulation for desired performance characteristics in construction applications.

Chemical Composition Differences

The C3A (tricalcium aluminate) phase contains a higher proportion of aluminum oxide (Al2O3) compared to the C3S (tricalcium silicate) phase, which is primarily composed of calcium oxide (CaO) and silica (SiO2). C3A typically consists of about 65-70% CaO and 30-35% Al2O3, whereas C3S contains approximately 67-70% CaO and 20-25% SiO2 with minor amounts of Al2O3 and Fe2O3. These chemical composition differences significantly influence their hydration behavior and the mechanical properties of cement.

Crystal Structures of C3A and C3S

The crystal structure of C3A (tricalcium aluminate) is characterized by a cubic lattice with a perovskite-type arrangement, facilitating rapid hydration kinetics crucial in early cement strength development. In contrast, C3S (tricalcium silicate) possesses a monoclinic or rhombohedral crystal structure, which contributes to slower hydration but significantly impacts long-term strength gain in Portland cement. The distinct crystal symmetries and atomic arrangements in C3A and C3S influence their reactivity and phase transformation behavior during the cement hydration process.

Role in Cement Hydration

C3A (Tricalcium Aluminate) rapidly reacts with water during cement hydration, producing heat and forming ettringite, which provides early strength but can cause setting time issues if uncontrolled. C3S (Tricalcium Silicate) hydrates more slowly but is responsible for the majority of strength development in later stages by forming calcium silicate hydrate (C-S-H) gel. Understanding the distinct roles of C3A and C3S can help you optimize cement formulations for balanced setting times and long-term durability.

Influence on Setting Time

C3A (tricalcium aluminate) significantly accelerates the initial setting time of cement due to rapid hydration, producing substantial heat and early strength development. In contrast, C3S (tricalcium silicate) governs the primary strength gain and contributes to both early and long-term setting phases by hydrating more slowly but steadily. The balanced proportion of C3A and C3S in cement formulations optimizes the setting time and strength progression, influencing workability and structural performance.

Effects on Concrete Strength Development

C3S (tricalcium silicate) significantly contributes to early strength development in concrete, typically within the first 7 days, due to its rapid hydration and calcium silicate hydrate (C-S-H) formation. C3A (tricalcium aluminate) reacts quickly with water and gypsum to form ettringite, influencing setting time but providing minimal long-term strength contributions. The predominance of C3S ensures higher compressive strength growth over time, whereas C3A affects initial setting behavior and sulfate resistance rather than concrete's ultimate strength.

Impact on Durability and Sulfate Resistance

C3A (tricalcium aluminate) reacts rapidly with water causing early heat release and increased vulnerability to sulfate attack, which can lead to reduced concrete durability in sulfate-rich environments. In contrast, C3S (tricalcium silicate) hydrates more slowly and contributes significantly to long-term strength and improved durability by forming a stable calcium silicate hydrate matrix. Optimizing your concrete mix to reduce C3A content while enhancing C3S ensures better sulfate resistance and longer-lasting structural performance.

Heat of Hydration: C3A vs C3S

C3A (tricalcium aluminate) generates a rapid heat of hydration, leading to a sharp temperature rise within the first few hours of cement hydration, whereas C3S (tricalcium silicate) produces a moderate heat release over an extended period. The intense exothermic reaction of C3A contributes to early strength development but can cause thermal cracking in large concrete pours if not controlled. C3S primarily drives long-term strength gain by sustaining hydration heat over several days, promoting gradual cement hardening and structural integrity.

Applications in Modern Cement Blends

C3S (tricalcium silicate) and C3A (tricalcium aluminate) phases play critical roles in modern cement blends, influencing both setting time and durability. C3S primarily contributes to early strength development and long-term hardness, making it vital for structural concrete applications, while C3A affects the initial setting and resistance to sulfate attack, tailored through sulfate adjustments in blended cements. Optimizing the proportions of C3A and C3S in cement formulations enhances performance characteristics such as workability, setting time, and chemical resistance in diverse construction environments.

Summary and Key Takeaways

C3A (Tricalcium Aluminate) reacts quickly during the hydration process, contributing to early strength but also causing rapid heat generation and potential flash setting in cement. C3S (Tricalcium Silicate) hydrates more slowly, providing sustained strength development and long-term durability in concrete structures. Understanding the balance between C3A and C3S phases helps optimize your cement mix for both early setting and enduring performance.

C3A vs C3S Phase Infographic

libmatt.com

libmatt.com