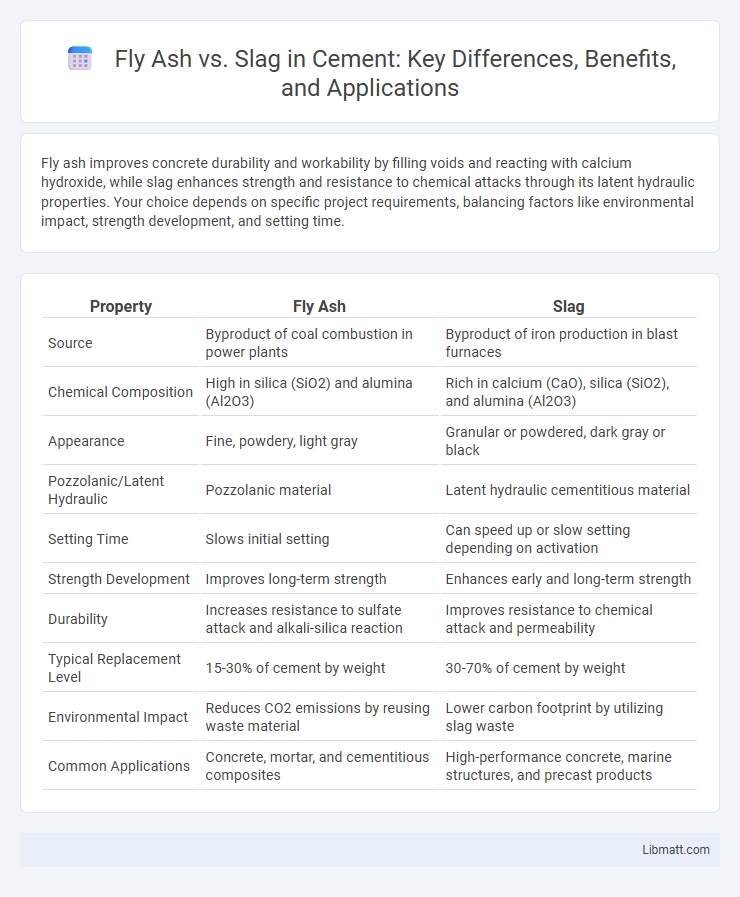

Fly ash improves concrete durability and workability by filling voids and reacting with calcium hydroxide, while slag enhances strength and resistance to chemical attacks through its latent hydraulic properties. Your choice depends on specific project requirements, balancing factors like environmental impact, strength development, and setting time.

Table of Comparison

| Property | Fly Ash | Slag |

|---|---|---|

| Source | Byproduct of coal combustion in power plants | Byproduct of iron production in blast furnaces |

| Chemical Composition | High in silica (SiO2) and alumina (Al2O3) | Rich in calcium (CaO), silica (SiO2), and alumina (Al2O3) |

| Appearance | Fine, powdery, light gray | Granular or powdered, dark gray or black |

| Pozzolanic/Latent Hydraulic | Pozzolanic material | Latent hydraulic cementitious material |

| Setting Time | Slows initial setting | Can speed up or slow setting depending on activation |

| Strength Development | Improves long-term strength | Enhances early and long-term strength |

| Durability | Increases resistance to sulfate attack and alkali-silica reaction | Improves resistance to chemical attack and permeability |

| Typical Replacement Level | 15-30% of cement by weight | 30-70% of cement by weight |

| Environmental Impact | Reduces CO2 emissions by reusing waste material | Lower carbon footprint by utilizing slag waste |

| Common Applications | Concrete, mortar, and cementitious composites | High-performance concrete, marine structures, and precast products |

Introduction to Fly Ash and Slag

Fly ash is a fine powder byproduct generated from burning pulverized coal in thermal power plants, commonly used as a supplementary cementitious material in concrete to enhance strength and durability. Slag, specifically ground granulated blast furnace slag (GGBFS), is a vitreous byproduct from the blast furnace process in steel manufacturing, valued for its cementitious properties that improve concrete's workability and corrosion resistance. Both materials contribute to sustainable construction by reducing the environmental impact of cement production through waste reutilization and lowered carbon emissions.

Origins and Production Processes

Fly ash originates from the combustion of pulverized coal in power plants, where fine particles are collected from exhaust gases using electrostatic precipitators or bag filters. Slag is produced during the smelting of iron ore in blast furnaces, formed as a byproduct when impurities separate from molten iron and solidify upon cooling. Understanding these distinct production processes helps you select the appropriate material to optimize concrete mix performance and sustainability.

Chemical Composition Differences

Fly ash primarily consists of silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3), whereas slag contains higher amounts of calcium oxide (CaO) along with silica and alumina. The chemical composition differences influence their reactivity and suitability in cementitious materials, with slag providing enhanced early strength due to its lime content. Understanding these variations helps you select the appropriate supplementary cementitious material for specific construction needs.

Physical Properties Comparison

Fly ash particles are typically spherical with a smooth surface, enhancing workability and reducing water demand in concrete mixtures, while slag particles are angular with a rough texture, contributing to increased strength and durability. The density of fly ash ranges from 2.1 to 2.6 g/cm3, slightly lower than granulated blast furnace slag, which is around 2.9 g/cm3, affecting the overall weight and performance of the blended cement. When choosing between these materials for your construction needs, understanding their distinct physical properties helps optimize mix design and achieve desired concrete characteristics.

Performance in Concrete Applications

Fly ash enhances concrete durability by improving workability, reducing permeability, and increasing long-term strength through pozzolanic reactions. Slag, particularly ground granulated blast-furnace slag (GGBFS), contributes to superior sulfate resistance and higher compressive strength development over time. Both supplementary cementitious materials optimize concrete performance by lowering heat of hydration and improving resistance to chemical attack, making them ideal for sustainable construction.

Environmental Impact Assessment

Fly ash and slag are industrial byproducts commonly used as supplementary cementitious materials in concrete, significantly reducing carbon dioxide emissions compared to Portland cement. Fly ash, a residue from coal combustion, helps divert waste from landfills and reduces greenhouse gas emissions, though concerns about trace heavy metals persist. Slag, a byproduct of steel production, offers significant environmental benefits by recycling waste and lowering energy consumption in cement manufacturing, contributing to reduced carbon footprints and improved sustainability.

Cost and Availability Factors

Fly ash is generally more cost-effective than slag due to its widespread availability as a byproduct of coal combustion in power plants, reducing material expenses for construction projects. Slag production depends on the steel manufacturing industry, which limits its regional availability and can lead to higher transportation and procurement costs. When planning your material sourcing, consider local supply chains to optimize budget and ensure timely access to either fly ash or slag for concrete and cement applications.

Advantages of Fly Ash in Construction

Fly ash enhances concrete durability and workability by improving its strength and reducing permeability, leading to longer-lasting structures. It also promotes sustainability by recycling industrial byproducts, lowering cement demand, and reducing carbon emissions in construction projects. Your choice of fly ash can result in cost-effective, eco-friendly building materials with superior performance characteristics.

Benefits of Using Slag in Construction

Slag offers significant benefits in construction, including enhanced durability and improved resistance to chemical attack, which extends the lifespan of concrete structures. Using slag reduces greenhouse gas emissions by lowering cement demand, making your projects more environmentally sustainable. Its ability to improve workability and reduce permeability also strengthens the overall performance of building materials.

Choosing Between Fly Ash and Slag

Choosing between fly ash and slag as supplementary cementitious materials depends on project-specific factors such as strength requirements, setting time, and environmental conditions. Fly ash is known for improving workability and reducing heat of hydration, making it ideal for large-scale concrete pours, while slag enhances long-term strength and durability, especially in aggressive environments. Your decision should consider these performance attributes alongside availability and cost-effectiveness to optimize concrete quality and sustainability.

Fly Ash vs Slag Infographic

libmatt.com

libmatt.com