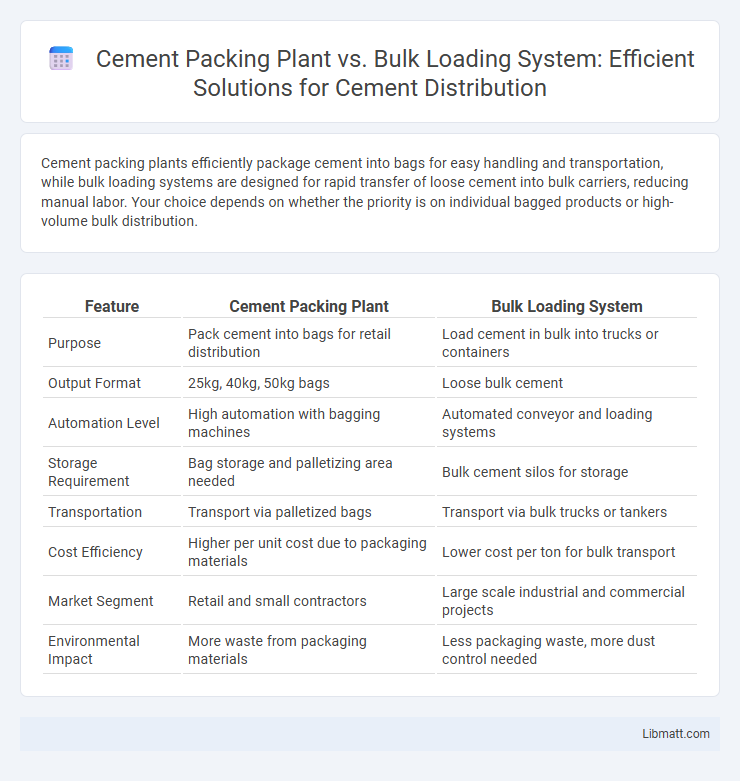

Cement packing plants efficiently package cement into bags for easy handling and transportation, while bulk loading systems are designed for rapid transfer of loose cement into bulk carriers, reducing manual labor. Your choice depends on whether the priority is on individual bagged products or high-volume bulk distribution.

Table of Comparison

| Feature | Cement Packing Plant | Bulk Loading System |

|---|---|---|

| Purpose | Pack cement into bags for retail distribution | Load cement in bulk into trucks or containers |

| Output Format | 25kg, 40kg, 50kg bags | Loose bulk cement |

| Automation Level | High automation with bagging machines | Automated conveyor and loading systems |

| Storage Requirement | Bag storage and palletizing area needed | Bulk cement silos for storage |

| Transportation | Transport via palletized bags | Transport via bulk trucks or tankers |

| Cost Efficiency | Higher per unit cost due to packaging materials | Lower cost per ton for bulk transport |

| Market Segment | Retail and small contractors | Large scale industrial and commercial projects |

| Environmental Impact | More waste from packaging materials | Less packaging waste, more dust control needed |

Introduction to Cement Packing Plant and Bulk Loading System

Cement packing plants automate the process of filling cement into bags, ensuring precise weight control and efficient packaging for distribution. Bulk loading systems, on the other hand, handle large volumes of cement by transferring it directly into transportation vehicles or silos without individual packaging. Your choice between these systems depends on operational scale, handling preferences, and distribution methods.

Overview of Cement Packing Plant Operations

Cement packing plant operations involve automated machinery that fills, seals, and labels bags with precise quantities of cement, ensuring efficient packaging for transportation and retail distribution. Key components include bag fillers, conveyors, palletizers, and quality control systems designed to handle high-volume production while maintaining product integrity. These plants optimize labor costs and reduce material waste by integrating real-time monitoring and automated controls.

Fundamentals of Bulk Loading System for Cement

Bulk loading systems for cement utilize automated conveyors and pneumatic equipment to transfer cement directly into transport vehicles, minimizing dust emissions and product loss. These systems incorporate sealed loading spouts, flow control valves, and dust collection units to ensure hygienic and efficient handling. Unlike traditional cement packing plants, bulk loading systems emphasize continuous flow, reducing labor costs and enabling faster turnaround times in high-volume cement distribution.

Efficiency Comparison: Packing Plant vs Bulk Loading

The Cement Packing Plant offers precise packaging with consistent weight control, reducing material waste and enhancing product quality, which suits smaller-scale or customer-specific orders. The Bulk Loading System excels in speed and volume handling, loading large quantities of cement directly into transport vehicles, significantly reducing labor costs and turnaround times for bulk shipments. Your choice depends on whether operational efficiency prioritizes packaging precision or large-scale volume throughput.

Cost Analysis: Packaging vs Bulk Cement Transportation

Cement packing plants incur higher operational costs due to material expenses for bags, labor for manual or automated packing, and storage requirements, while bulk loading systems reduce packaging costs by transporting cement in large quantities via tanker trucks or railcars. Bulk transportation lowers per-ton handling and logistics expenses, improving efficiency and minimizing product loss from spillage or contamination. Your choice between these systems depends on volume needs, delivery infrastructure, and long-term cost-effectiveness in cement distribution.

Environmental Impact of Cement Packing vs Bulk Loading

The environmental impact of cement packing plants versus bulk loading systems differs significantly due to variations in dust generation and energy consumption. Cement packing plants typically produce higher levels of particulate emissions from bagging operations, requiring advanced dust collection systems to mitigate air pollution. Bulk loading systems reduce packaging waste and dust emissions, offering a more sustainable solution by minimizing environmental contaminants and optimizing resource use in cement distribution.

Labor and Maintenance Requirements

Cement packing plants demand higher labor input due to manual bagging and frequent equipment adjustments, increasing operational costs and downtime. Bulk loading systems require less labor as automated processes streamline material transfer, reducing human intervention and maintenance frequency. Maintenance in packing plants involves regular inspection of bagging machines and conveyors, while bulk systems focus on maintaining pumps and pipelines for consistent flow and minimal wear.

Packaging Quality and Product Safety Considerations

Cement packing plants ensure high packaging quality by using automated bagging machines that control bag fill weights and minimize contamination, supporting consistent product density and integrity. Bulk loading systems prioritize product safety through sealed pneumatic or mechanical transfer methods that reduce dust emissions and prevent moisture ingress during transport. Both systems maintain cement quality by addressing contamination risks and environmental protection, but packing plants provide superior product traceability and consumer-ready packaging.

Market Demand and Distribution Flexibility

The cement packing plant caters to diverse packaging needs, boosting market demand by enabling efficient distribution through bags suitable for retail and small-scale consumers. In contrast, bulk loading systems target large-scale operations with higher throughput, optimizing supply chains for industrial clients by facilitating direct bulk transport to cement silos or trucks. Distribution flexibility favors cement packing plants in fragmented markets, while bulk loading systems excel in centralized distribution networks requiring rapid, large volume dispatch.

Future Trends in Cement Packing and Bulk Loading Technologies

Emerging trends in cement packing plants emphasize automation and smart sensor integration for enhanced accuracy and reduced labor costs, while bulk loading systems are advancing towards modular designs and IoT-enabled monitoring to optimize logistics and minimize downtime. Increased adoption of eco-friendly practices, such as dust suppression technologies and energy-efficient machinery, is transforming both packing and bulk loading operations to meet stricter environmental regulations. The convergence of AI-powered predictive maintenance and data analytics is set to revolutionize operational efficiency, ensuring higher throughput and reduced operational risks in cement handling facilities.

Cement Packing Plant vs Bulk Loading System Infographic

libmatt.com

libmatt.com