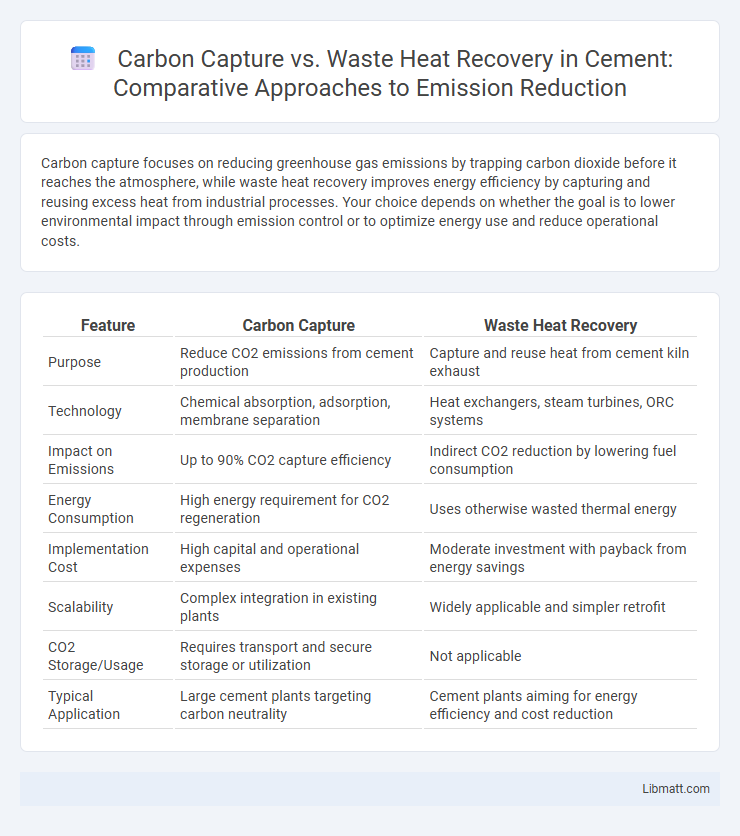

Carbon capture focuses on reducing greenhouse gas emissions by trapping carbon dioxide before it reaches the atmosphere, while waste heat recovery improves energy efficiency by capturing and reusing excess heat from industrial processes. Your choice depends on whether the goal is to lower environmental impact through emission control or to optimize energy use and reduce operational costs.

Table of Comparison

| Feature | Carbon Capture | Waste Heat Recovery |

|---|---|---|

| Purpose | Reduce CO2 emissions from cement production | Capture and reuse heat from cement kiln exhaust |

| Technology | Chemical absorption, adsorption, membrane separation | Heat exchangers, steam turbines, ORC systems |

| Impact on Emissions | Up to 90% CO2 capture efficiency | Indirect CO2 reduction by lowering fuel consumption |

| Energy Consumption | High energy requirement for CO2 regeneration | Uses otherwise wasted thermal energy |

| Implementation Cost | High capital and operational expenses | Moderate investment with payback from energy savings |

| Scalability | Complex integration in existing plants | Widely applicable and simpler retrofit |

| CO2 Storage/Usage | Requires transport and secure storage or utilization | Not applicable |

| Typical Application | Large cement plants targeting carbon neutrality | Cement plants aiming for energy efficiency and cost reduction |

Introduction to Carbon Capture and Waste Heat Recovery

Carbon capture involves trapping carbon dioxide emissions from industrial processes to reduce greenhouse gases and combat climate change. Waste heat recovery captures excess thermal energy from equipment or industrial operations, converting it into usable power or heat to improve energy efficiency. Understanding these technologies helps you enhance sustainability and lower operational costs in energy-intensive industries.

Understanding Carbon Capture Technologies

Carbon capture technologies focus on capturing carbon dioxide emissions from industrial sources or the atmosphere to reduce greenhouse gases and combat climate change. Waste heat recovery involves capturing excess heat from industrial processes and converting it into usable energy, thereby improving energy efficiency and reducing fuel consumption. You can integrate both technologies to enhance sustainability by lowering emissions and maximizing energy utilization.

Fundamentals of Waste Heat Recovery Systems

Waste heat recovery systems capture and reuse heat generated by industrial processes, improving energy efficiency and reducing operational costs. These systems typically include heat exchangers, recuperators, or regenerators to transfer thermal energy from exhaust gases to incoming process streams. You can enhance overall sustainability by implementing waste heat recovery alongside carbon capture technologies to lower emissions and optimize resource use.

Environmental Impact: Carbon Emissions vs. Energy Efficiency

Carbon capture technology significantly reduces carbon emissions by directly capturing CO2 from industrial sources, mitigating greenhouse gas accumulation in the atmosphere. Waste heat recovery enhances energy efficiency by reclaiming excess thermal energy from industrial processes, lowering fuel consumption and indirectly decreasing emissions. Both methods contribute to environmental sustainability, with carbon capture targeting emission reduction and waste heat recovery optimizing energy use.

Economic Feasibility and Cost Comparison

Carbon capture technology requires significant upfront investment and operational costs, often ranging from $40 to $120 per ton of CO2 captured, making it less economically feasible for small-scale applications. Waste heat recovery systems typically involve lower installation expenses and offer rapid payback periods by reducing energy consumption, enhancing overall cost-effectiveness. Your choice between these technologies depends on the scale of operations and long-term savings, with waste heat recovery generally presenting a more economically viable option for immediate energy cost reduction.

Industrial Applications: Where Each Technology Excels

Carbon capture excels in industrial applications with high CO2 emissions such as cement production, steel manufacturing, and natural gas processing, effectively reducing greenhouse gas output. Waste heat recovery is highly effective in industries with significant heat losses like power plants, chemical manufacturing, and pulp and paper mills, improving energy efficiency and lowering fuel consumption. Both technologies complement each other by targeting different aspects of industrial emissions and energy use for sustainability.

Integration with Renewable Energy Sources

Carbon capture technology enhances the integration of renewable energy sources by reducing carbon emissions from fossil fuel-based power plants, enabling a cleaner energy transition. Waste heat recovery systems complement renewables by capturing excess heat from industrial processes and converting it into electricity, thereby improving overall energy efficiency and reducing reliance on non-renewable fuels. Your renewable energy strategy benefits from combining both technologies to maximize sustainability and lower environmental impact.

Challenges and Limitations of Both Approaches

Carbon capture faces challenges such as high energy consumption, significant costs, and complexities in capturing and storing CO2 safely for the long term. Waste heat recovery systems are limited by the temperature and quality of the heat source, installation costs, and equipment maintenance requirements, which can reduce their overall efficiency. Understanding these limitations will help you evaluate the most feasible solution for your energy and environmental goals.

Future Outlook: Innovations in Carbon Capture and Waste Heat Recovery

Innovations in carbon capture technology are rapidly advancing with developments like direct air capture and carbon mineralization enhancing efficiency and scalability. Waste heat recovery systems are integrating smart sensors and advanced materials to maximize energy recapture from industrial processes and reduce overall emissions. Your investment in these evolving technologies could significantly contribute to sustainable industrial decarbonization and energy optimization.

Choosing the Right Solution: Key Factors to Consider

Selecting between carbon capture and waste heat recovery depends on your facility's primary emissions and energy efficiency goals. Carbon capture is essential for reducing CO2 emissions in industries with high carbon output, while waste heat recovery improves energy utilization by reclaiming excess thermal energy. Consider factors such as the type of pollutants, cost implications, implementation complexity, and long-term sustainability when determining the optimal solution for your operations.

Carbon capture vs Waste heat recovery Infographic

libmatt.com

libmatt.com