Air slides offer a low-friction method for transporting fine, dry bulk materials using a cushion of air, making them energy-efficient and ideal for delicate powders. Screw conveyors provide precise movement of materials through a rotating helical blade enclosed in a tube, giving you reliable control for handling abrasive or sticky substances in various industries.

Table of Comparison

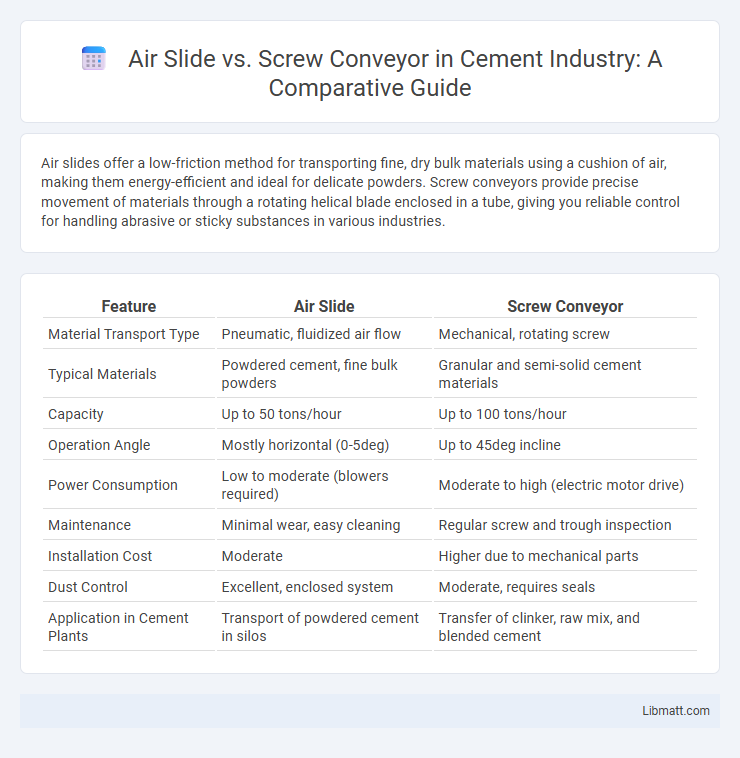

| Feature | Air Slide | Screw Conveyor |

|---|---|---|

| Material Transport Type | Pneumatic, fluidized air flow | Mechanical, rotating screw |

| Typical Materials | Powdered cement, fine bulk powders | Granular and semi-solid cement materials |

| Capacity | Up to 50 tons/hour | Up to 100 tons/hour |

| Operation Angle | Mostly horizontal (0-5deg) | Up to 45deg incline |

| Power Consumption | Low to moderate (blowers required) | Moderate to high (electric motor drive) |

| Maintenance | Minimal wear, easy cleaning | Regular screw and trough inspection |

| Installation Cost | Moderate | Higher due to mechanical parts |

| Dust Control | Excellent, enclosed system | Moderate, requires seals |

| Application in Cement Plants | Transport of powdered cement in silos | Transfer of clinker, raw mix, and blended cement |

Introduction to Air Slides and Screw Conveyors

Air slides utilize a fluidized bed bed concept to gently transport fine, dry bulk materials using a controlled airflow that reduces friction and material degradation. Screw conveyors consist of a rotating helical screw blade inside a tubular or trough casing, designed to move granular or semi-solid materials efficiently through a controlled mechanical action. Your choice between these systems depends on factors such as material characteristics, desired speed, and maintenance requirements.

How Air Slides Work: Operating Principles

Air slides operate by using a thin layer of air to fluidize fine powders, allowing materials to flow smoothly over a porous membrane with minimal friction. This pneumatic principle relies on low air pressure, which suspends particles and enables gentle, continuous movement ideal for handling sensitive or dusty materials. Your choice between air slides and screw conveyors depends on the material characteristics and process requirements, as air slides excel in efficient, low-maintenance conveying of fine, dry powders.

How Screw Conveyors Work: Operating Principles

Screw conveyors operate by utilizing a rotating helical screw blade, known as an auger, inside a tube or trough to move materials along its length. The rotation of the screw propels bulk solids, powders, or granules through the conveyor, making it effective for horizontal or inclined transport. This mechanism differs from air slides, which use a fluidized air bed for material movement, highlighting screw conveyors' reliance on mechanical force rather than pneumatic flow.

Key Differences Between Air Slides and Screw Conveyors

Air slides transport bulk materials using a fluidized air bed, ensuring gentle handling and preventing material degradation, ideal for powders and fine particles in industries like cement and chemicals. Screw conveyors use a rotating helical screw blade within a trough to move semi-solid materials, suitable for handling coarse bulk materials and offering precise control over material flow in agriculture and wastewater treatment. Air slides provide energy-efficient, low-noise operation with minimal maintenance, whereas screw conveyors excel in versatility and durability but require more power and maintenance due to mechanical wear.

Material Suitability for Air Slides vs Screw Conveyors

Air slides excel in handling fine, dry, and free-flowing materials such as powders and granules, relying on aeration to maintain material fluidity. Screw conveyors are better suited for transporting semi-solid, abrasive, or cohesive materials, providing controlled movement through a rotating helical screw. Your choice depends on the material's moisture content, particle size, and abrasiveness to ensure efficient and reliable conveyance.

Energy Consumption Comparison

Air slides generally consume less energy than screw conveyors because they use low-pressure air to fluidize bulk materials, minimizing mechanical movement and friction. Screw conveyors require continuous rotational power to drive the screw shaft, resulting in higher energy usage, especially with dense or abrasive materials. Energy efficiency in air slides can reach up to 50% savings compared to screw conveyors under optimal conditions.

Maintenance Requirements: Air Slide vs Screw Conveyor

Air slides require minimal maintenance due to their lack of moving parts, reducing wear and tear and minimizing downtime. Screw conveyors demand regular inspection and lubrication of bearings, seals, and flights to prevent mechanical failure and ensure optimal performance. Maintenance costs for screw conveyors typically exceed those of air slides because of their complex mechanical components.

Installation and Space Considerations

Air slide conveyors require minimal structural support and can be installed at slight inclines, saving valuable floor space in industrial settings. Screw conveyors demand more robust frameworks due to their heavier components and often need increased overhead clearance for maintenance and operation. Choosing between these systems depends on available installation space, with air slides favored in compact facilities and screw conveyors suited for environments with ample room and heavier material handling needs.

Cost Analysis: Air Slide vs Screw Conveyor

Air slide conveyors generally offer lower initial capital costs compared to screw conveyors due to simpler design and lower material requirements. However, air slides often incur higher operational expenses related to energy consumption and maintenance of air compressors, while screw conveyors typically have increased costs associated with wear parts and motor maintenance. Your decision should balance upfront investment against long-term operating costs to determine the most cost-effective solution.

Choosing the Right System for Your Application

Selecting between an air slide and a screw conveyor depends on material properties and application requirements, such as bulk density, abrasiveness, and flowability. Air slides excel in handling fine, dry powders with low moisture content and minimal degradation, offering energy-efficient, low-maintenance operation. Screw conveyors are preferred for cohesive, moist, or abrasive materials requiring precise metering, handling heavier loads with strong mechanical components and adaptable configurations.

Air Slide vs Screw Conveyor Infographic

libmatt.com

libmatt.com