Grinding media consists of solid particles, such as balls or rods, used in mills to crush and grind materials through mechanical impact and attrition, enhancing particle size reduction. Grinding aids are chemical additives that improve milling efficiency by reducing energy consumption, preventing material agglomeration, and enhancing your overall grinding performance.

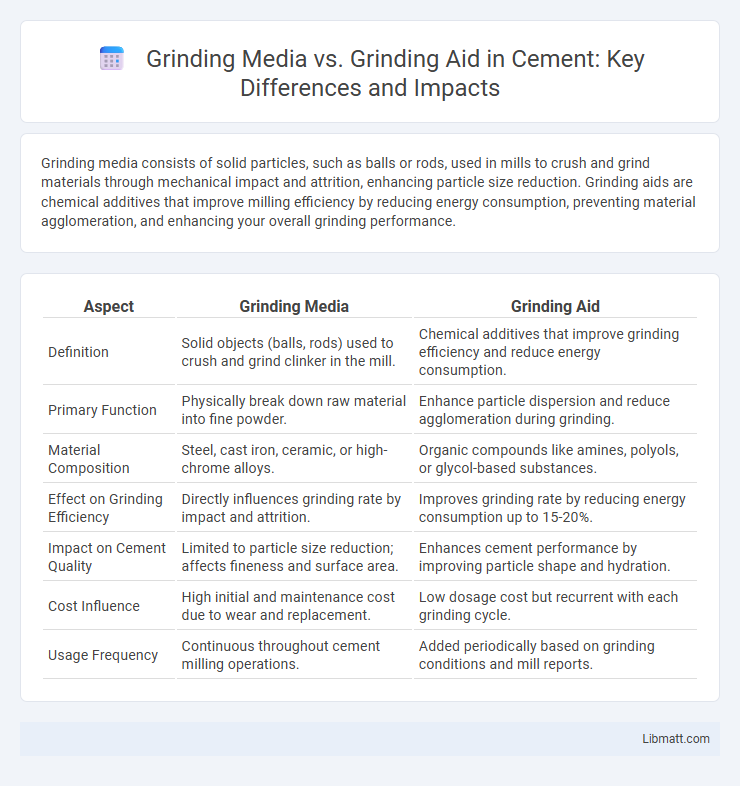

Table of Comparison

| Aspect | Grinding Media | Grinding Aid |

|---|---|---|

| Definition | Solid objects (balls, rods) used to crush and grind clinker in the mill. | Chemical additives that improve grinding efficiency and reduce energy consumption. |

| Primary Function | Physically break down raw material into fine powder. | Enhance particle dispersion and reduce agglomeration during grinding. |

| Material Composition | Steel, cast iron, ceramic, or high-chrome alloys. | Organic compounds like amines, polyols, or glycol-based substances. |

| Effect on Grinding Efficiency | Directly influences grinding rate by impact and attrition. | Improves grinding rate by reducing energy consumption up to 15-20%. |

| Impact on Cement Quality | Limited to particle size reduction; affects fineness and surface area. | Enhances cement performance by improving particle shape and hydration. |

| Cost Influence | High initial and maintenance cost due to wear and replacement. | Low dosage cost but recurrent with each grinding cycle. |

| Usage Frequency | Continuous throughout cement milling operations. | Added periodically based on grinding conditions and mill reports. |

Understanding Grinding Media: Definition and Types

Grinding media refers to the materials used in mills to facilitate the grinding process by impacting and attriting particles to reduce their size. Common types of grinding media include steel balls, ceramic balls, and flint pebbles, each selected based on factors like hardness, density, and abrasion resistance to optimize milling efficiency. The choice of grinding media directly influences the grinding rate, product fineness, and energy consumption in mineral processing and manufacturing industries.

What Are Grinding Aids? Functions and Varieties

Grinding aids are chemical additives used in the milling process to improve the efficiency of grinding by reducing energy consumption and preventing particle agglomeration. Their primary functions include enhancing material flow, increasing mill throughput, and improving particle size distribution by reducing the surface energy of particles. Common varieties of grinding aids include amines, glycol ethers, and fatty acids, each selected based on the specific material and grinding conditions to optimize your milling performance.

Key Differences Between Grinding Media and Grinding Aid

Grinding media are solid materials like balls or rods used in mills to physically break down particles through impact and attrition, while grinding aids are chemical additives that improve the efficiency of the grinding process by reducing energy consumption and preventing material agglomeration. Grinding media directly influence particle size reduction and grinding efficiency, whereas grinding aids modify surface properties to enhance mill throughput and product quality. Understanding these key differences helps optimize your milling operations by selecting the appropriate combination for improved performance and reduced operational costs.

Mechanisms of Action: How Grinding Media Works

Grinding media operates by impacting and attriting the material within a mill, breaking particles through kinetic energy and mechanical force applied during tumbling motions. The media's size, density, and hardness directly influence the efficiency of particle size reduction and uniformity. These collisions facilitate fracturing and grinding, promoting more effective milling compared to chemical methods like grinding aids.

Mechanisms of Action: How Grinding Aid Improves Efficiency

Grinding aid improves efficiency by reducing the surface energy of particles, which minimizes agglomeration and enhances grinding efficiency. Unlike grinding media that directly impacts and breaks particles physically, grinding aids chemically interact with particle surfaces to prevent dust generation and reduce energy consumption. Your milling process benefits from smoother material flow and increased throughput due to the synergistic effect of grinding aids on grinding media performance.

Impact on Particle Size Distribution

Grinding media directly influences particle size distribution by impacting the efficiency of comminution, with varying sizes and materials ensuring precise breakage and uniform granularity. Grinding aids, on the other hand, enhance grinding efficiency by reducing particle agglomeration and surface energy, leading to finer and more consistent particle sizes. Optimizing the use of both grinding media and grinding aids can significantly improve your control over particle size distribution in milling processes.

Energy Consumption: Media vs Aid Efficiency

Grinding media directly impact energy consumption by facilitating particle size reduction through mechanical forces, often requiring significant power to maintain motion and impact. Grinding aids improve energy efficiency by reducing material agglomeration and surface tension, enabling smoother grinding at lower energy inputs. Comparing both, grinding aids optimize energy use by enhancing media effectiveness, reducing overall power demand in grinding operations.

Cost Analysis: Comparing Grinding Media and Aids

Grinding media typically incur higher upfront costs due to material hardness and durability requirements, impacting long-term operational expenses through wear replacement frequency. Grinding aids, though relatively inexpensive per unit, can reduce overall energy consumption and grinding time, providing cost savings in energy bills and equipment maintenance. Evaluating total cost-effectiveness involves balancing the capital investment in grinding media against the efficiency improvements and reduced operational costs enabled by grinding aids.

Effects on Product Quality and Fineness

Grinding media directly impact product quality and fineness by influencing the intensity and efficiency of particle size reduction in milling processes, ensuring uniformity and desired surface area. Grinding aids enhance the grinding efficiency by reducing energy consumption and preventing particle agglomeration, leading to finer and more consistent product texture. Your choice between grinding media and grinding aid depends on optimizing particle size distribution and maintaining the desired physical and chemical properties of the final product.

Environmental and Operational Considerations

Grinding media, typically made from steel or ceramic, require periodic replacement due to wear, impacting waste management and operational costs, whereas grinding aids reduce energy consumption by enhancing mill efficiency and promoting finer particle size distribution, thereby lowering carbon emissions. Grinding aids chemically interact with materials to reduce surface tension, enabling smoother grinding with less energy input, while grinding media contribute to physical abrasion but generate debris that demands proper disposal. Environmentally, the use of grinding aids supports sustainable operations by decreasing power demand and enabling longer mill lifespan, contrasting with grinding media that impose higher maintenance and handling challenges.

Grinding Media vs Grinding Aid Infographic

libmatt.com

libmatt.com