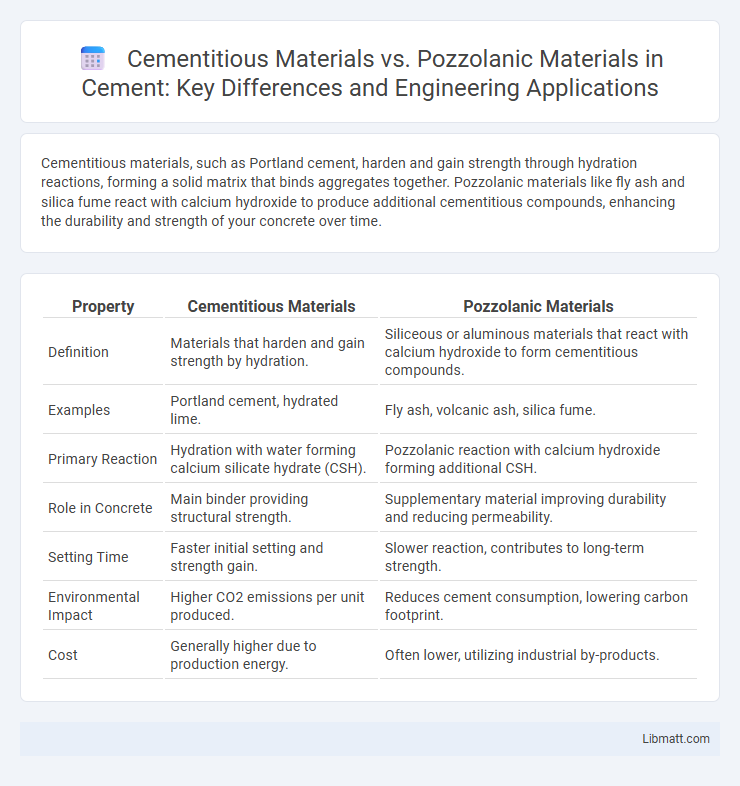

Cementitious materials, such as Portland cement, harden and gain strength through hydration reactions, forming a solid matrix that binds aggregates together. Pozzolanic materials like fly ash and silica fume react with calcium hydroxide to produce additional cementitious compounds, enhancing the durability and strength of your concrete over time.

Table of Comparison

| Property | Cementitious Materials | Pozzolanic Materials |

|---|---|---|

| Definition | Materials that harden and gain strength by hydration. | Siliceous or aluminous materials that react with calcium hydroxide to form cementitious compounds. |

| Examples | Portland cement, hydrated lime. | Fly ash, volcanic ash, silica fume. |

| Primary Reaction | Hydration with water forming calcium silicate hydrate (CSH). | Pozzolanic reaction with calcium hydroxide forming additional CSH. |

| Role in Concrete | Main binder providing structural strength. | Supplementary material improving durability and reducing permeability. |

| Setting Time | Faster initial setting and strength gain. | Slower reaction, contributes to long-term strength. |

| Environmental Impact | Higher CO2 emissions per unit produced. | Reduces cement consumption, lowering carbon footprint. |

| Cost | Generally higher due to production energy. | Often lower, utilizing industrial by-products. |

Introduction to Cementitious and Pozzolanic Materials

Cementitious materials primarily include Portland cement, which acts as a binder that hardens and gains strength through hydration. Pozzolanic materials, such as fly ash or silica fume, do not possess cementitious properties on their own but react with calcium hydroxide in the presence of water to form additional cementitious compounds. Understanding the chemical composition and reactivity of these materials can help enhance the durability and performance of Your concrete mixtures.

Definitions: Cementitious vs Pozzolanic Materials

Cementitious materials are substances that possess the intrinsic ability to harden and bind aggregates when mixed with water, such as Portland cement and lime. Pozzolanic materials, including fly ash, silica fume, and volcanic ash, do not set on their own but react chemically with calcium hydroxide in the presence of moisture to form compounds with cementitious properties. Understanding this distinction helps you optimize concrete mix designs for improved durability and strength.

Chemical Composition Differences

Cementitious materials primarily consist of calcium silicates, calcium aluminates, and calcium aluminoferrites, which hydrate and harden upon mixing with water. Pozzolanic materials are rich in silica, alumina, and iron oxide but lack calcium and rely on a chemical reaction with calcium hydroxide to form cementitious compounds. The key chemical distinction is that cementitious materials inherently possess calcium oxide (CaO), whereas pozzolanic materials are calcium-deficient and contribute reactive silica and alumina for secondary cementitious reactions.

Sources and Types of Cementitious Materials

Cementitious materials primarily include Portland cement, slag cement, and gypsum, derived from limestone, clay, slag, and natural minerals, providing the main binding properties in concrete. Pozzolanic materials consist of natural volcanic ash, fly ash from coal combustion, silica fume from silicon production, and calcined clay, which react chemically with calcium hydroxide to enhance durability and strength. Understanding these sources and types helps you select the best materials for optimized construction performance and sustainability.

Sources and Types of Pozzolanic Materials

Pozzolanic materials originate from natural sources such as volcanic ash, diatomaceous earth, and calcined clay, or from industrial by-products like fly ash and silica fume, which react with calcium hydroxide to form cementitious compounds. These materials enhance the durability and strength of concrete by improving its microstructure and reducing permeability when combined with traditional cementitious materials like Portland cement. Your choice between cementitious and pozzolanic materials depends on the availability, environmental impact, and desired performance characteristics for construction applications.

Hydration and Reaction Mechanisms

Cementitious materials undergo hydration through the chemical reaction of clinker phases with water, forming calcium silicate hydrate (C-S-H) and calcium hydroxide as primary products that contribute to strength development. Pozzolanic materials, in contrast, react primarily with the calcium hydroxide released during cement hydration, producing additional C-S-H gel that enhances durability and reduces permeability. Understanding the distinct hydration and reaction mechanisms of these materials allows you to optimize concrete mix designs for improved mechanical performance and longevity.

Performance in Concrete Mixes

Cementitious materials, such as ordinary Portland cement, provide essential hydration reactions that contribute to early strength development and durability in concrete mixes. Pozzolanic materials, including fly ash and silica fume, enhance long-term strength and reduce permeability by reacting with calcium hydroxide, resulting in a denser and more chemically resistant matrix. Combining cementitious and pozzolanic components improves overall concrete performance by increasing durability, reducing shrinkage, and enhancing resistance to sulfate attack and alkali-silica reaction.

Advantages and Limitations of Each Material

Cementitious materials, including Portland cement, offer high early strength and reliable setting times, making them suitable for rapid construction projects, but they often have higher carbon emissions and limited resistance to chemical attacks. Pozzolanic materials, such as fly ash and silica fume, enhance durability, reduce permeability, and lower environmental impact by consuming calcium hydroxide during hydration; however, they typically exhibit slower strength gain and require longer curing periods. Your choice depends on balancing performance requirements and sustainability goals, as cementitious materials prioritize strength while pozzolans improve durability and ecological footprint.

Applications in Construction Industry

Cementitious materials, including Portland cement and blended cements, are essential in creating structural components like concrete, mortar, and grout due to their high strength and durability. Pozzolanic materials, such as fly ash, silica fume, and volcanic ash, enhance concrete properties by improving workability, reducing permeability, and increasing resistance to chemical attacks when used as supplementary cementitious materials (SCMs). Your choice between these materials influences concrete performance, cost-efficiency, and environmental sustainability in construction projects.

Sustainability and Environmental Impact

Cementitious materials, including Portland cement, generally have a higher carbon footprint due to energy-intensive production and significant CO2 emissions. Pozzolanic materials, such as fly ash and silica fume, enhance sustainability by utilizing industrial by-products that reduce cement demand and lower overall environmental impact. By incorporating pozzolanic materials, your construction projects can achieve improved durability while minimizing greenhouse gas emissions and conserving natural resources.

Cementitious materials vs Pozzolanic materials Infographic

libmatt.com

libmatt.com