Asphalt cement offers flexible, water-resistant properties ideal for road surfacing and roofing, while hydraulic cement provides rapid-setting, high-strength characteristics perfect for repairing cracks and sealing leaks in concrete structures. Understanding the specific application of each cement type ensures your project benefits from optimal durability and performance.

Table of Comparison

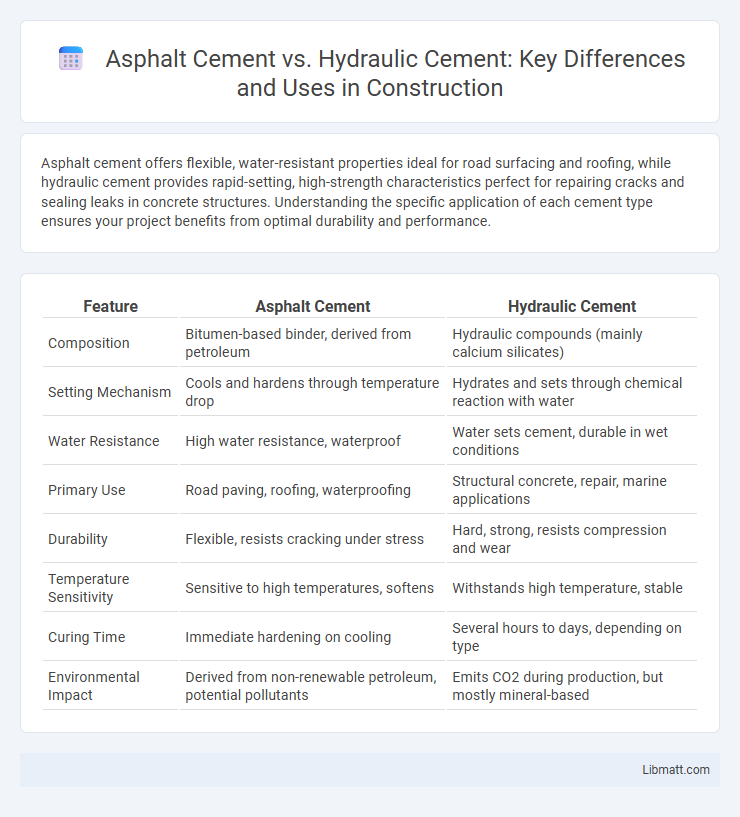

| Feature | Asphalt Cement | Hydraulic Cement |

|---|---|---|

| Composition | Bitumen-based binder, derived from petroleum | Hydraulic compounds (mainly calcium silicates) |

| Setting Mechanism | Cools and hardens through temperature drop | Hydrates and sets through chemical reaction with water |

| Water Resistance | High water resistance, waterproof | Water sets cement, durable in wet conditions |

| Primary Use | Road paving, roofing, waterproofing | Structural concrete, repair, marine applications |

| Durability | Flexible, resists cracking under stress | Hard, strong, resists compression and wear |

| Temperature Sensitivity | Sensitive to high temperatures, softens | Withstands high temperature, stable |

| Curing Time | Immediate hardening on cooling | Several hours to days, depending on type |

| Environmental Impact | Derived from non-renewable petroleum, potential pollutants | Emits CO2 during production, but mostly mineral-based |

Introduction to Asphalt Cement and Hydraulic Cement

Asphalt cement, a petroleum-based binder, is widely used in road construction for its flexibility, waterproofing properties, and ability to withstand temperature fluctuations. Hydraulic cement, primarily composed of Portland cement, sets and hardens through a chemical reaction with water, making it ideal for concrete and mortar applications due to its high strength and quick curing time. Both materials play critical roles in construction, with asphalt cement favored for pavement surfaces and hydraulic cement essential for structural elements.

Composition and Material Properties

Asphalt cement is a bituminous material composed of hydrocarbons, primarily derived from crude oil refining, known for its flexibility, water resistance, and adhesive qualities, making it ideal for road surfacing and waterproofing. Hydraulic cement, typically made from materials like Portland cement, calcium silicates, and calcium aluminates, reacts chemically with water to harden quickly and gain strength, providing excellent durability and load-bearing capacity for concrete structures. Your choice between asphalt and hydraulic cement depends on the specific application requirements, such as flexibility versus structural strength and cure time.

Manufacturing Processes

Asphalt cement is produced through the distillation and refining of crude oil, where heavy residual fractions are heated and oxidized to achieve the desired viscosity and adhesion properties. Hydraulic cement, such as Portland cement, is manufactured by heating limestone and clay at high temperatures in a kiln to form clinker, which is then ground into a fine powder and mixed with gypsum. Understanding these manufacturing processes helps you select the appropriate cement type for specific construction needs based on durability and application requirements.

Key Differences in Chemical Structure

Asphalt cement primarily consists of bitumen, a complex mixture of hydrocarbons with high molecular weight, characterized by its hydrophobic nature and viscoelastic properties. Hydraulic cement, such as Portland cement, contains calcium silicates and aluminates that chemically react with water to form strong, insoluble calcium silicate hydrates, giving it hydraulic hardening capabilities. The fundamental chemical difference lies in asphalt cement's non-reactive, organic hydrocarbon composition versus hydraulic cement's inorganic, water-reactive calcium compounds essential for setting and strength development.

Applications in Construction

Asphalt cement is primarily used in road construction, parking lots, and roofing due to its flexibility and water-resistant properties. Hydraulic cement is ideal for structural applications like foundations, bridges, and water-retaining structures because it sets and hardens quickly through a chemical reaction with water. Your choice depends on whether you need durability and waterproofing for pavements or strong, fast-setting material for load-bearing projects.

Performance in Various Environments

Asphalt cement demonstrates superior flexibility and waterproofing qualities, making it ideal for roads and pavements exposed to temperature fluctuations and moisture. Hydraulic cement, known for its rapid setting and high compressive strength, excels in underwater or wet conditions such as dams and foundations. Your choice depends on environmental exposure and performance requirements, where asphalt suits dynamic and wet surfaces, while hydraulic cement is best for structural applications needing quick setting and durability.

Durability and Longevity Comparison

Asphalt cement exhibits excellent flexibility and water resistance, making it ideal for road surfaces that endure frequent traffic and temperature fluctuations, contributing to moderate longevity of 10-20 years under typical conditions. Hydraulic cement, such as Portland cement, provides superior compressive strength and chemical resistance, resulting in exceptional durability and lifespan exceeding 50 years, especially in structural applications like bridges and buildings. The longevity of hydraulic cement outperforms asphalt cement in static load-bearing environments, while asphalt cement's elasticity offers advantages in pavement durability under dynamic loads.

Environmental Impact and Sustainability

Asphalt cement, derived from petroleum, has a higher environmental impact due to greenhouse gas emissions and non-renewable resource consumption, whereas hydraulic cement, primarily made from limestone and clay, involves significant CO2 emissions during production but can incorporate industrial byproducts like fly ash to enhance sustainability. Asphalt's recyclability rate exceeds 90%, reducing landfill waste and resource use, while hydraulic cement's use of supplementary cementitious materials can lower carbon footprint and improve durability. Innovations in both materials focus on reducing environmental burdens through recycled content and alternative production methods.

Cost Analysis and Economic Considerations

Asphalt cement typically offers lower initial costs compared to hydraulic cement, making it more economical for projects requiring flexibility and faster application. Hydraulic cement, while more expensive upfront, provides superior durability and resistance to water, which can reduce long-term maintenance expenses and lifecycle costs. Your choice should weigh immediate budget constraints against potential savings from extended service life and reduced repair frequency.

Choosing the Right Cement for Your Project

Choosing the right cement ensures optimal durability and performance in construction projects. Asphalt cement provides flexibility and waterproofing, ideal for pavements and road repairs, while hydraulic cement offers rapid setting and strong bonding in concrete and masonry applications. Understanding your project's specific needs and environmental conditions helps you select the most suitable cement for long-lasting results.

Asphalt Cement vs Hydraulic Cement Infographic

libmatt.com

libmatt.com