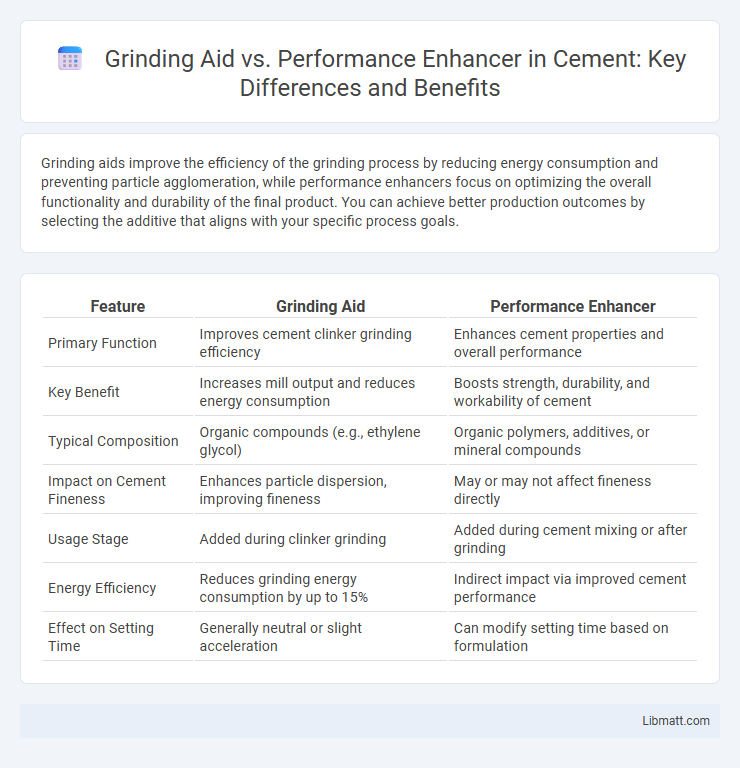

Grinding aids improve the efficiency of the grinding process by reducing energy consumption and preventing particle agglomeration, while performance enhancers focus on optimizing the overall functionality and durability of the final product. You can achieve better production outcomes by selecting the additive that aligns with your specific process goals.

Table of Comparison

| Feature | Grinding Aid | Performance Enhancer |

|---|---|---|

| Primary Function | Improves cement clinker grinding efficiency | Enhances cement properties and overall performance |

| Key Benefit | Increases mill output and reduces energy consumption | Boosts strength, durability, and workability of cement |

| Typical Composition | Organic compounds (e.g., ethylene glycol) | Organic polymers, additives, or mineral compounds |

| Impact on Cement Fineness | Enhances particle dispersion, improving fineness | May or may not affect fineness directly |

| Usage Stage | Added during clinker grinding | Added during cement mixing or after grinding |

| Energy Efficiency | Reduces grinding energy consumption by up to 15% | Indirect impact via improved cement performance |

| Effect on Setting Time | Generally neutral or slight acceleration | Can modify setting time based on formulation |

Introduction to Cement Additives

Grinding aids and performance enhancers are essential cement additives designed to improve the efficiency and quality of cement production. Grinding aids reduce energy consumption by preventing particle agglomeration during the grinding process, leading to finer and more uniform cement particles. Performance enhancers optimize the final cement properties, such as strength development and durability, by modifying hydration kinetics and improving workability.

Defining Grinding Aids

Grinding aids are chemical additives that improve the efficiency and fineness of the milling process by reducing energy consumption and preventing particle agglomeration. These substances enhance the grinding mechanism, resulting in finer cement or mineral powders with better flow properties. Your choice of grinding aid can significantly impact mill throughput and overall plant performance.

Understanding Performance Enhancers

Performance enhancers improve cement grinding efficiency by modifying particle surface properties, reducing agglomeration, and boosting mill throughput. Unlike grinding aids primarily designed to reduce energy consumption, performance enhancers target better particle dispersion and improved strength development in the final product. Your cement production benefits from optimized grindability and enhanced early cement strength when using tailored performance enhancers.

Key Differences Between Grinding Aids and Performance Enhancers

Grinding aids primarily improve the efficiency of the grinding process by reducing energy consumption and preventing particle agglomeration, while performance enhancers optimize the final product properties such as strength, durability, and setting time. Grinding aids enhance particle dispersion and reduce specific surface area, leading to better mill throughput, whereas performance enhancers modify hydration kinetics and microstructure of cement or concrete for superior mechanical performance. Your choice between these additives depends on whether the focus is on operational efficiency or the enhancement of end-product characteristics.

Mechanisms of Action: How Each Additive Works

Grinding aids improve cement grinding efficiency by reducing particle agglomeration and enhancing the separation of fine particles, resulting in a finer and more uniform grind. Performance enhancers work by modifying the hydration process and improving particle dispersion, which boosts strength development and durability. Your choice between these additives depends on whether you aim to optimize grinding energy consumption or enhance the final product's mechanical properties.

Impact on Cement Properties

Grinding aids improve cement properties by reducing energy consumption during milling and enhancing particle size distribution, leading to better workability and strength development. Performance enhancers influence cement hydration kinetics and microstructure, resulting in accelerated strength gain and improved durability of concrete. Your choice between these additives depends on whether you prioritize milling efficiency or enhanced long-term cement performance.

Dosage and Application Guidelines

Grinding aids typically require low dosage levels, often between 0.01% to 0.1% by weight of the material, and are added directly to the mill feed to reduce energy consumption and improve grinding efficiency. Performance enhancers, on the other hand, may have varied dosage guidelines depending on their chemical composition and target effect, often demanding precise application to optimize product quality and throughput. Ensuring accurate dosage according to manufacturer recommendations is crucial for maximizing benefits and avoiding negative impacts on your grinding process.

Environmental and Economic Considerations

Grinding aids reduce energy consumption by improving mill throughput, leading to lower greenhouse gas emissions and operational costs, while performance enhancers optimize particle size distribution for improved product quality and reduced waste. You can achieve significant cost savings with grinding aids due to decreased electricity usage, whereas performance enhancers contribute to longer equipment life and less maintenance expenditure. Both additives play crucial roles in sustainable industrial processes by minimizing environmental impact and maximizing economic efficiency.

Industry Best Practices and Case Studies

Industry best practices reveal that grinding aids primarily improve the efficiency of mechanical pulverization by reducing energy consumption and enhancing particle dispersion, while performance enhancers focus on optimizing the chemical and physical properties of the final product. Case studies in cement manufacturing demonstrate grinding aids like triethanolamine increasing mill throughput by up to 15%, whereas performance enhancers such as polymers improve compressive strength and setting time. Integrating both additives strategically has been shown to significantly boost overall process efficiency and product quality, reducing operational costs and enhancing sustainability.

Future Trends in Cement Additive Development

Grinding aids and performance enhancers in cement additive development are evolving rapidly with a focus on sustainability and efficiency. Innovations emphasize reducing energy consumption during grinding and improving cement hydration kinetics to enhance strength and durability. Nanotechnology and bio-based additives are emerging trends aimed at optimizing clinker reactivity and lowering carbon footprint in future cement production.

Grinding Aid vs Performance Enhancer Infographic

libmatt.com

libmatt.com