Clinkerization is the high-temperature process in cement manufacturing where raw materials are heated to form clinker nodules, while sintering involves heating powdered materials below their melting points to bond particles together without liquefaction. Understanding the differences between clinkerization and sintering helps you optimize industrial processes for improved material strength and energy efficiency.

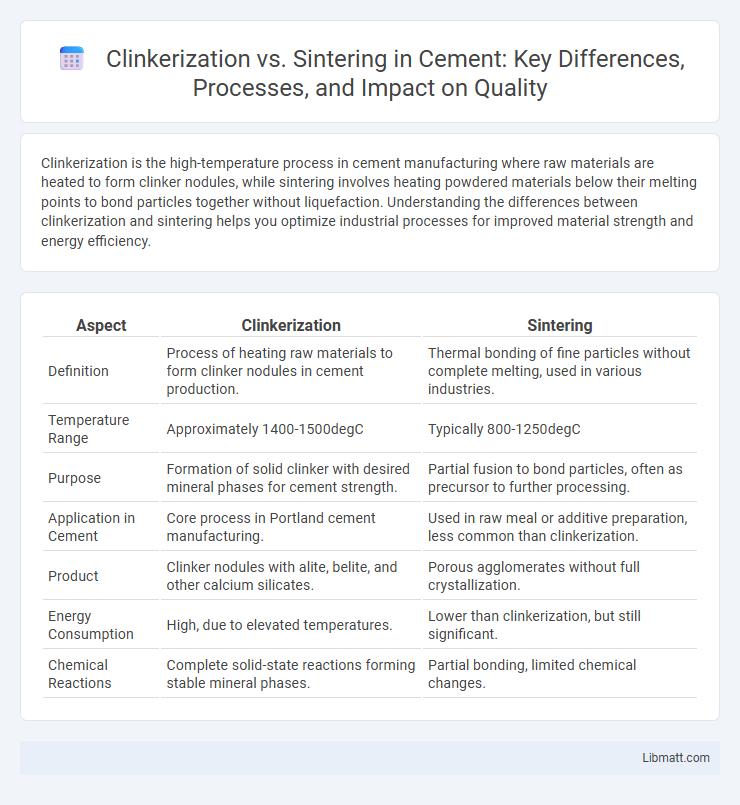

Table of Comparison

| Aspect | Clinkerization | Sintering |

|---|---|---|

| Definition | Process of heating raw materials to form clinker nodules in cement production. | Thermal bonding of fine particles without complete melting, used in various industries. |

| Temperature Range | Approximately 1400-1500degC | Typically 800-1250degC |

| Purpose | Formation of solid clinker with desired mineral phases for cement strength. | Partial fusion to bond particles, often as precursor to further processing. |

| Application in Cement | Core process in Portland cement manufacturing. | Used in raw meal or additive preparation, less common than clinkerization. |

| Product | Clinker nodules with alite, belite, and other calcium silicates. | Porous agglomerates without full crystallization. |

| Energy Consumption | High, due to elevated temperatures. | Lower than clinkerization, but still significant. |

| Chemical Reactions | Complete solid-state reactions forming stable mineral phases. | Partial bonding, limited chemical changes. |

Introduction to Clinkerization and Sintering

Clinkerization is a high-temperature process in cement manufacturing where raw materials are heated to form clinker nodules essential for cement production. Sintering involves heating powdered materials below their melting points to bond particles and create a solid mass, commonly used in metallurgy and ceramics. Understanding the differences between clinkerization and sintering helps optimize your industrial processes for improved material properties and energy efficiency.

Defining Clinkerization: Process and Principles

Clinkerization is a high-temperature process in cement production where raw materials such as limestone and clay are heated in a rotary kiln to form clinker nodules through a series of chemical reactions called calcination and clinker formation. This process involves the transformation of calcium carbonate into calcium oxide and the synthesis of silicates and aluminates essential for cement properties. Understanding clinkerization is crucial for optimizing your cement quality and energy efficiency compared to sintering, which typically refers to the agglomeration of fine particles at lower temperatures without melting.

Understanding the Sintering Process

The sintering process involves the heating of powdered materials below their melting point to bond particles together through diffusion, resulting in increased strength and structural integrity. Unlike clinkerization, which combines raw materials at extremely high temperatures to form clinker, sintering emphasizes particle cohesion without complete melting. Understanding sintering is crucial for optimizing your material properties in sectors like ceramics, metallurgy, and powder metallurgy.

Key Differences: Clinkerization vs Sintering

Clinkerization involves the heating of raw materials at high temperatures to form clinker nodules essential for cement production, while sintering primarily refers to the process of fusing powdered materials into a solid mass without melting. The key differences include the temperature range used, with clinkerization occurring at around 1450degC and sintering at lower temperatures typically between 900degC and 1300degC. Your choice between these processes depends on the desired material properties and industrial application, such as cement manufacturing or metallurgy.

Raw Materials Used in Clinkerization and Sintering

Clinkerization primarily uses a blend of limestone, clay, shale, and other minerals rich in calcium, silica, alumina, and iron oxides, ensuring the raw mix achieves the desired chemical composition for cement clinker formation. Sintering, on the other hand, often involves fine powders of raw materials such as iron ore fines, coke breeze, and fluxes like limestone or dolomite to create porous agglomerates suitable for blast furnace feed. Understanding the specific raw materials in your clinkerization or sintering process is crucial for optimizing fuel efficiency, chemical reactions, and product quality.

Temperature Profiles and Reaction Mechanisms

Clinkerization involves temperatures reaching approximately 1450degC, where raw materials undergo complex solid-state reactions forming clinker minerals like alite and belite, while sintering occurs at lower temperatures around 1100-1300degC, primarily involving partial melting and particle bonding without full mineral formation. The reaction mechanisms in clinkerization include decomposition of calcium carbonate and subsequent combination with silica and alumina phases, whereas sintering mainly promotes particle neck growth and densification through solid-state diffusion. Understanding these temperature profiles and mechanisms enables you to optimize material properties for cement production or ceramic applications.

Energy Consumption Comparison

Clinkerization consumes significantly more energy than sintering due to the higher temperatures required, typically reaching around 1450degC in clinker kilns compared to sintering temperatures of approximately 1200degC. The intense heat demand in clinkerization translates to increased fuel usage and higher carbon emissions, making it a less energy-efficient process. Optimizing your industrial operations by understanding these differences can lead to substantial energy savings and reduced environmental impact.

Applications in Cement and Materials Industries

Clinkerization involves heating raw materials to form clinker, a crucial process in cement production ensuring strong hydraulic properties and durability. Sintering, used in both cement and materials industries, fuses fine particles into a solid mass without melting, improving material density and mechanical strength. Cement manufacturing primarily relies on clinkerization for producing clinker nodules, while sintering enhances raw meal homogeneity and is vital in producing refractory and ceramic materials.

Environmental Impacts and Emissions

Clinkerization generates significantly higher CO2 emissions compared to sintering due to the calcination of limestone and high energy consumption in cement production. Sintering, primarily used in iron ore processing, emits lower greenhouse gases but can release particulate matter and nitrogen oxides from fuel combustion. Effective emission control technologies, such as electrostatic precipitators and selective catalytic reduction systems, are essential to mitigate environmental impacts in both processes.

Future Trends in Clinkerization and Sintering Technologies

Future trends in clinkerization focus on reducing CO2 emissions through advanced precalciner technology and alternative fuels, promoting energy efficiency and sustainability. Sintering technologies are evolving with innovations like low-temperature sintering and hybrid processes that minimize raw material consumption and improve product quality. Your cement production process can benefit from integrating these cutting-edge methods to enhance environmental performance and operational cost savings.

Clinkerization vs Sintering Infographic

libmatt.com

libmatt.com