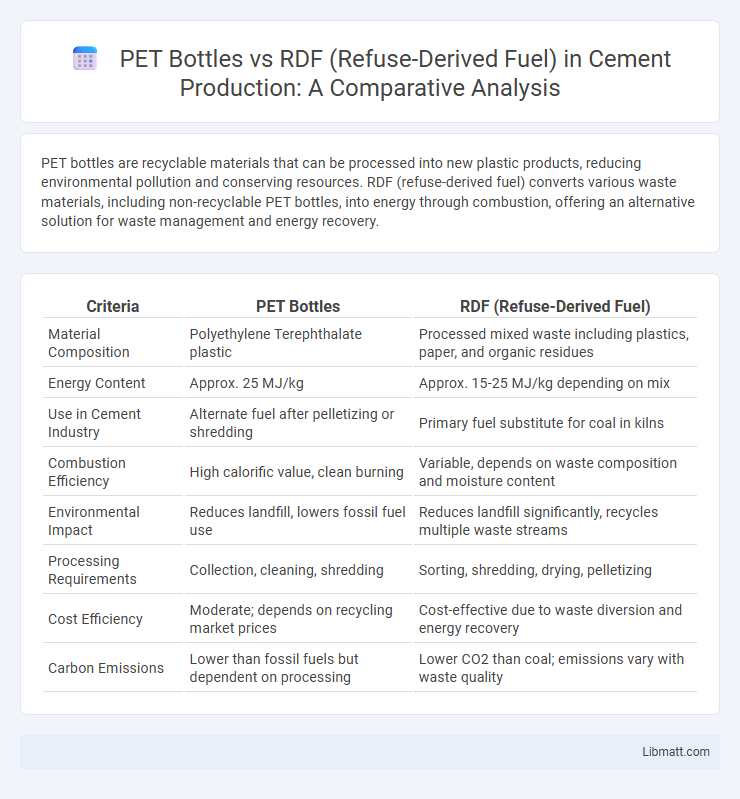

PET bottles are recyclable materials that can be processed into new plastic products, reducing environmental pollution and conserving resources. RDF (refuse-derived fuel) converts various waste materials, including non-recyclable PET bottles, into energy through combustion, offering an alternative solution for waste management and energy recovery.

Table of Comparison

| Criteria | PET Bottles | RDF (Refuse-Derived Fuel) |

|---|---|---|

| Material Composition | Polyethylene Terephthalate plastic | Processed mixed waste including plastics, paper, and organic residues |

| Energy Content | Approx. 25 MJ/kg | Approx. 15-25 MJ/kg depending on mix |

| Use in Cement Industry | Alternate fuel after pelletizing or shredding | Primary fuel substitute for coal in kilns |

| Combustion Efficiency | High calorific value, clean burning | Variable, depends on waste composition and moisture content |

| Environmental Impact | Reduces landfill, lowers fossil fuel use | Reduces landfill significantly, recycles multiple waste streams |

| Processing Requirements | Collection, cleaning, shredding | Sorting, shredding, drying, pelletizing |

| Cost Efficiency | Moderate; depends on recycling market prices | Cost-effective due to waste diversion and energy recovery |

| Carbon Emissions | Lower than fossil fuels but dependent on processing | Lower CO2 than coal; emissions vary with waste quality |

Introduction to PET Bottles and RDF

PET bottles are lightweight, durable containers predominantly used for packaging beverages and are highly recyclable, contributing to reducing plastic waste. RDF (refuse-derived fuel) is produced by processing non-recyclable waste, including plastics, into a fuel source for energy generation, offering an alternative to fossil fuels. Understanding the distinct roles of PET bottles and RDF in waste management helps optimize your recycling and energy recovery strategies.

Composition and Characteristics of PET Bottles

PET bottles are composed primarily of polyethylene terephthalate, a lightweight and transparent polymer known for its high strength and excellent barrier properties against moisture and gas. These bottles are recyclable and have a distinct chemical structure that makes them resistant to degradation, unlike refuse-derived fuel (RDF) which consists of mixed waste materials including plastics, paper, and organic matter. Your choice between PET bottles and RDF impacts waste management strategies due to the specific characteristics and recyclability of PET compared to the energy recovery focus of RDF.

Understanding Refuse-Derived Fuel (RDF)

Refuse-Derived Fuel (RDF) is a fuel produced from various types of waste, including plastics, paper, and organic materials, by processing and shredding refuse to create a combustible material. Unlike PET bottles, which are primarily recycled into new plastic products, RDF serves as an alternative energy source, often used in cement kilns and power plants to reduce reliance on fossil fuels. RDF contributes to waste management by diverting non-recyclable waste from landfills and converting it into usable energy, promoting sustainability through waste-to-energy conversion.

Environmental Impact: PET Bottles vs RDF

PET bottles contribute significantly to plastic pollution and take hundreds of years to decompose, leading to long-term environmental damage. RDF (refuse-derived fuel) offers a waste-to-energy solution that reduces landfill volume and lowers greenhouse gas emissions by converting non-recyclable waste, including PET, into usable energy. Your choice between PET bottle recycling and RDF impacts landfill waste management and carbon footprint, with RDF providing a more sustainable alternative for managing unrecyclable plastics.

Waste Management and Recycling Processes

PET bottles undergo mechanical recycling where they are cleaned, shredded, and melted into pellets for producing new plastic products, significantly reducing landfill waste and conserving resources. RDF (refuse-derived fuel) transforms non-recyclable waste materials into a fuel source through shredding and drying, offering an alternative energy recovery method but producing emissions and losing material recyclability. Your choice between these processes impacts environmental sustainability, with PET recycling promoting circular economy goals while RDF emphasizes waste-to-energy solutions.

Energy Recovery Potential of RDF

Refuse-derived fuel (RDF) offers a significantly higher energy recovery potential compared to PET bottles, as RDF is composed of combustible materials that can be converted efficiently into thermal energy for industrial use. PET bottles primarily require mechanical recycling to recover value, whereas RDF captures energy through processes like incineration or gasification, contributing to reduced landfill use and fossil fuel consumption. By utilizing RDF, your waste management strategy can enhance sustainability through improved waste-to-energy conversion, supporting circular economy goals.

Economic Aspects: Costs and Benefits

PET bottles offer significant economic advantages through recycling processes that reduce raw material costs and create value-added products, whereas RDF (refuse-derived fuel) presents financial benefits by diverting waste from landfills and generating alternative energy that lowers fossil fuel consumption costs. The recycling of PET bottles typically demands less energy and infrastructure investment compared to RDF production, leading to more stable market prices and job creation within the circular economy. However, RDF provides an essential economic benefit in waste management by reducing landfill fees and producing revenue from energy sales, balancing costs associated with sorting and processing heterogeneous waste streams.

Regulatory Framework and Standards

PET bottles are regulated under stringent recycling and waste management standards such as the EU's Packaging and Packaging Waste Directive and the U.S. EPA's Resource Conservation and Recovery Act (RCRA), ensuring high-quality material recovery and reduced environmental impact. RDF (refuse-derived fuel) is governed by waste-to-energy regulations including the EU's Waste Framework Directive and standards like ISO 21640, which define fuel quality parameters and emissions limits to minimize pollution from combustion processes. Compliance with these regulatory frameworks is essential for both PET recycling and RDF production to meet environmental safety, product quality, and sustainability goals.

Innovations in PET and RDF Utilization

Innovations in PET bottle recycling include chemical depolymerization, transforming waste into high-quality monomers for new plastics and packaging, significantly reducing environmental impact. In RDF utilization, advanced sorting and processing technologies enhance fuel quality, enabling efficient energy recovery from mixed municipal solid waste while lowering greenhouse gas emissions. Your sustainable waste management strategy can benefit from integrating these cutting-edge PET recycling and RDF conversion methods to optimize resource recovery and minimize landfill dependence.

Future Trends and Sustainable Solutions

PET bottles are increasingly being recycled into high-quality raw materials, promoting a circular economy and reducing plastic pollution. Refuse-derived fuel (RDF) offers an alternative waste-to-energy solution by converting non-recyclable plastics and municipal solid waste into energy, lowering landfill dependency. Future trends emphasize integrating advanced sorting technologies and improving chemical recycling methods to enhance sustainability and resource efficiency in both PET bottle recycling and RDF production.

PET bottles vs RDF (refuse-derived fuel) Infographic

libmatt.com

libmatt.com