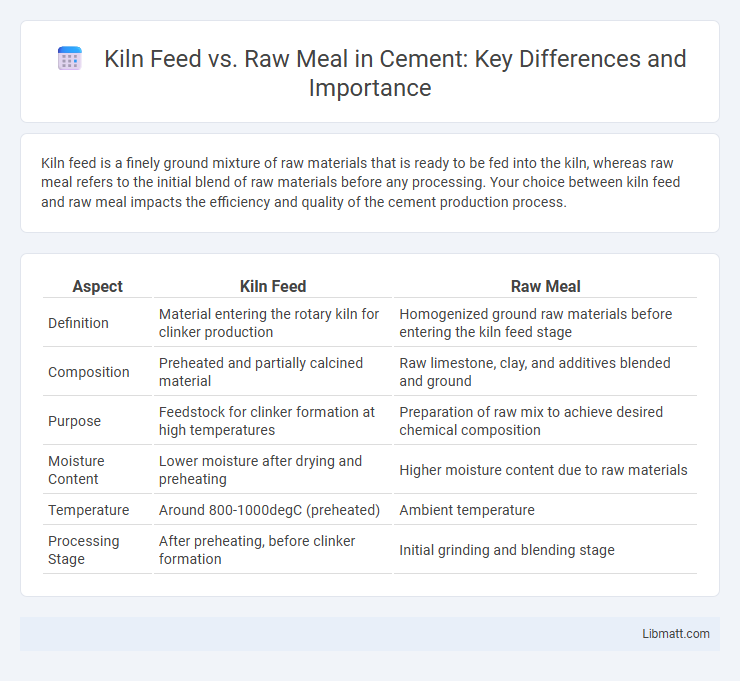

Kiln feed is a finely ground mixture of raw materials that is ready to be fed into the kiln, whereas raw meal refers to the initial blend of raw materials before any processing. Your choice between kiln feed and raw meal impacts the efficiency and quality of the cement production process.

Table of Comparison

| Aspect | Kiln Feed | Raw Meal |

|---|---|---|

| Definition | Material entering the rotary kiln for clinker production | Homogenized ground raw materials before entering the kiln feed stage |

| Composition | Preheated and partially calcined material | Raw limestone, clay, and additives blended and ground |

| Purpose | Feedstock for clinker formation at high temperatures | Preparation of raw mix to achieve desired chemical composition |

| Moisture Content | Lower moisture after drying and preheating | Higher moisture content due to raw materials |

| Temperature | Around 800-1000degC (preheated) | Ambient temperature |

| Processing Stage | After preheating, before clinker formation | Initial grinding and blending stage |

Introduction to Kiln Feed and Raw Meal

Kiln feed and raw meal are essential components in cement manufacturing, with kiln feed being the homogenized blend of raw meal prepared for the rotary kiln. Raw meal consists of finely ground raw materials including limestone, clay, and additives, calibrated to achieve the desired chemical composition. The precise control and preparation of raw meal influence kiln feed quality, directly impacting clinker formation and overall cement performance.

Definition of Kiln Feed

Kiln feed is the finely ground mixture of raw materials, primarily limestone, clay, and sand, prepared for the kiln in cement production. It differs from raw meal, which refers to the initial blended and homogenized raw materials before drying and grinding into kiln feed. Kiln feed quality directly influences clinker formation and cement quality, making its precise composition critical in the manufacturing process.

Definition of Raw Meal

Raw meal is a finely ground mixture of raw materials such as limestone, clay, and sand that serves as the primary input for the kiln feed in cement manufacturing. It undergoes blending and homogenization to ensure chemical consistency before being fed into the kiln for clinker production. Your understanding of raw meal is crucial for optimizing the kiln feed process and improving cement quality.

Key Differences Between Kiln Feed and Raw Meal

Kiln feed and raw meal differ primarily in particle size and moisture content, with kiln feed being finer and drier to ensure optimal burning in the kiln. Raw meal is a homogenized blend of raw materials before heating, whereas kiln feed is processed and conditioned raw meal ready for the kiln. The transformation from raw meal to kiln feed enhances calcination efficiency and clinker quality in cement production.

Importance of Kiln Feed in Cement Production

Kiln feed plays a crucial role in cement production by ensuring the homogeneity of raw materials before entering the kiln, directly impacting the clinker quality and energy efficiency. Unlike raw meal, kiln feed is the processed and blended mixture optimized for consistent chemical composition, supporting stable kiln operation. Proper control of kiln feed composition reduces fuel consumption and improves product strength, making it indispensable for efficient cement manufacturing.

Composition of Raw Meal

Raw meal is a carefully blended mixture of various raw materials such as limestone, clay, shale, and sand, primarily composed of calcium carbonate, silica, alumina, and iron oxide. This precise composition ensures the correct chemical balance for clinker formation in the kiln, affecting the quality and efficiency of your cement production. The kiln feed is essentially the processed raw meal after homogenization and grinding, optimized for stable kiln operation and consistent output.

Processing Steps: From Raw Meal to Kiln Feed

Raw meal is produced by grinding and homogenizing raw materials such as limestone, clay, and sand to create a consistent blend suitable for cement production. This raw meal undergoes drying and fine grinding to achieve the necessary particle size and moisture content before being transferred as kiln feed. Kiln feed refers to the conditioned raw meal ready for insertion into the rotary kiln, where it will undergo calcination and clinker formation.

Quality Control in Raw Meal and Kiln Feed Preparation

Quality control in raw meal and kiln feed preparation centers on precise particle size distribution, chemical composition, and moisture content to ensure consistent kiln performance and clinker quality. Advanced analytical techniques such as X-ray fluorescence (XRF) and near-infrared (NIR) spectroscopy enable real-time monitoring and adjustments, minimizing deviations and reducing the risk of kiln blockages. Maintaining homogeneity and stability in raw meal ensures optimal combustion and clinker formation, directly impacting cement strength and production efficiency.

Impact of Kiln Feed and Raw Meal on Clinker Formation

Kiln feed and raw meal composition critically influence clinker mineralogy and quality during cement production. Variations in chemical components such as CaO, SiO2, Al2O3, and Fe2O3 in kiln feed affect the formation temperature and stability of key clinker phases like alite and belite. Precise control of raw meal granulometry and chemical uniformity enhances clinker formation efficiency, reducing energy consumption and improving cement strength.

Optimizing Kiln Feed and Raw Meal for Efficiency

Optimizing kiln feed and raw meal composition directly enhances clinker production efficiency by ensuring consistent chemical homogeneity and particle size distribution. Precise control of the CaO/SiO2 ratio and moisture content in your raw meal minimizes energy consumption and reduces kiln coating formation, leading to smoother kiln operation. Tailoring raw meal blending based on real-time material analysis improves burnability, maximizing fuel efficiency and overall kiln performance.

Kiln feed vs Raw meal Infographic

libmatt.com

libmatt.com