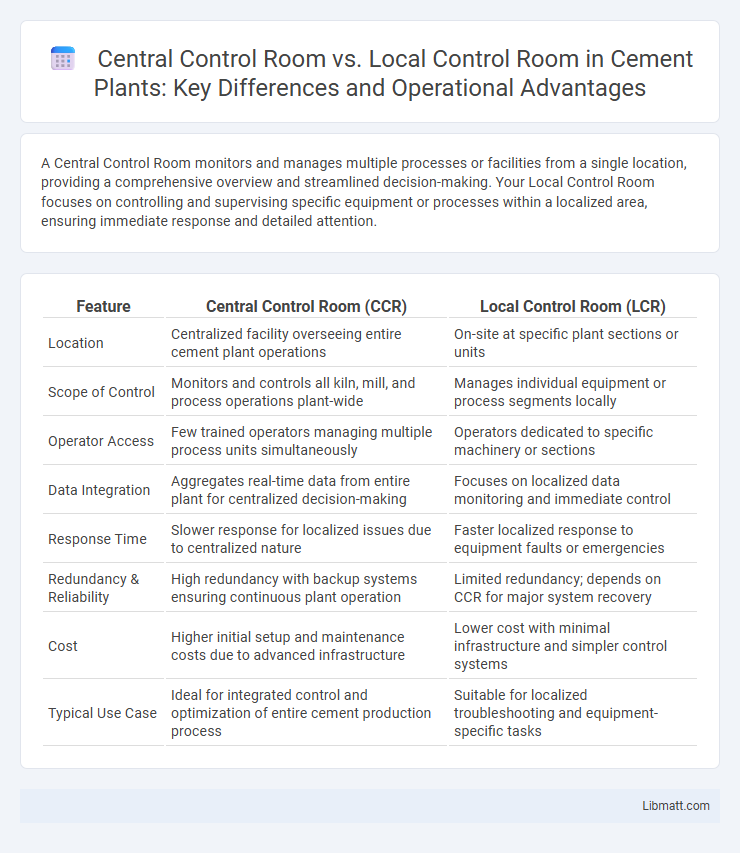

A Central Control Room monitors and manages multiple processes or facilities from a single location, providing a comprehensive overview and streamlined decision-making. Your Local Control Room focuses on controlling and supervising specific equipment or processes within a localized area, ensuring immediate response and detailed attention.

Table of Comparison

| Feature | Central Control Room (CCR) | Local Control Room (LCR) |

|---|---|---|

| Location | Centralized facility overseeing entire cement plant operations | On-site at specific plant sections or units |

| Scope of Control | Monitors and controls all kiln, mill, and process operations plant-wide | Manages individual equipment or process segments locally |

| Operator Access | Few trained operators managing multiple process units simultaneously | Operators dedicated to specific machinery or sections |

| Data Integration | Aggregates real-time data from entire plant for centralized decision-making | Focuses on localized data monitoring and immediate control |

| Response Time | Slower response for localized issues due to centralized nature | Faster localized response to equipment faults or emergencies |

| Redundancy & Reliability | High redundancy with backup systems ensuring continuous plant operation | Limited redundancy; depends on CCR for major system recovery |

| Cost | Higher initial setup and maintenance costs due to advanced infrastructure | Lower cost with minimal infrastructure and simpler control systems |

| Typical Use Case | Ideal for integrated control and optimization of entire cement production process | Suitable for localized troubleshooting and equipment-specific tasks |

Introduction to Control Room Concepts

Central Control Room (CCR) serves as the primary hub for monitoring and managing multiple operations or processes across an entire facility, enabling comprehensive oversight and coordinated decision-making. Local Control Room (LCR) operates closer to individual equipment or specific process units, allowing for immediate, hands-on control and quicker response times in localized areas. Both control rooms integrate real-time data visualization, alarm management, and communication systems to ensure operational safety and efficiency in industrial environments.

Defining Central Control Room

A Central Control Room (CCR) serves as the primary hub for monitoring and managing operations across multiple sites or processes within an industrial facility, utilizing centralized data collection and control systems. Unlike a Local Control Room that oversees specific, limited areas or individual units, the CCR integrates information from various sources to enable comprehensive decision-making and real-time coordination. Equipped with advanced SCADA systems, real-time data analytics, and remote access capabilities, the Central Control Room optimizes operational efficiency and enhances safety management on a facility-wide scale.

Defining Local Control Room

A Local Control Room (LCR) is a dedicated facility situated close to the operational site, designed for direct monitoring and control of specific processes or equipment. Unlike a Central Control Room, which oversees multiple sites or systems remotely, the LCR provides immediate, hands-on management to swiftly address localized issues. Your operational efficiency improves with an LCR by enabling rapid decision-making and real-time response to site-specific conditions.

Key Functional Differences

Central Control Rooms (CCRs) manage and monitor entire facilities or multiple sites using integrated systems for real-time data analysis and decision-making, prioritizing centralized oversight and coordination. Local Control Rooms (LCRs) focus on specific processes or areas within a facility, providing immediate response capabilities with direct control of localized equipment and operations. CCRs enable strategic management and long-term planning, while LCRs ensure tactical execution and quick troubleshooting at the operational level.

Advantages of Central Control Rooms

Central Control Rooms offer superior operational efficiency by integrating data from multiple sources into a single interface, enabling real-time monitoring and quicker decision-making. Enhanced communication and coordination in Central Control Rooms reduce response times during emergencies compared to isolated Local Control Rooms. The scalability and advanced analytics capabilities in Central Control Rooms support proactive maintenance and resource optimization across entire facilities or networks.

Benefits of Local Control Rooms

Local Control Rooms offer enhanced operational efficiency by providing immediate access to system data and real-time monitoring specific to the facility or process location. They reduce response times to alarms or emergencies, enabling quicker decision-making and minimizing potential risks. Decentralized control also supports tailored, site-specific adjustments and maintenance, improving overall system reliability and safety.

Challenges and Limitations

Central Control Rooms face challenges such as communication delays, risk of single-point failures, and limited situational awareness due to distance from operational sites. Local Control Rooms have limitations including restricted scope of control, less integration with overall system monitoring, and potential redundancy in resource allocation. Your operational efficiency can be impacted by these constraints, requiring a careful balance between centralized oversight and localized responsiveness.

Application Scenarios and Industries

Central Control Rooms are primarily used in large-scale industries such as oil and gas, power generation, and transportation, where integrated monitoring and centralized decision-making across multiple sites is crucial. Local Control Rooms are prevalent in manufacturing plants, water treatment facilities, and smaller industrial operations, allowing on-site operators to manage and respond promptly to process variations. Both setups optimize operational efficiency but differ in scope, with Central Control Rooms supporting strategic oversight and Local Control Rooms focusing on immediate process control.

Emerging Trends in Control Room Design

Emerging trends in control room design emphasize the integration of centralized and local control rooms through advanced digital twin technology and AI-driven analytics to enhance operational efficiency and real-time decision-making. Central control rooms are evolving into dynamic hubs equipped with high-resolution video walls and augmented reality interfaces that provide comprehensive system overviews, while local control rooms adopt modular, ergonomic workstations tailored for situational responsiveness. The growing use of cloud-based platforms facilitates seamless data sharing between central and local control environments, promoting collaborative incident management and predictive maintenance strategies.

Choosing the Right Control Room Solution

Choosing the right control room solution depends on your facility's scale, complexity, and operational requirements. Central Control Rooms consolidate monitoring and management in a single location, enhancing coordination for large industrial plants, while Local Control Rooms provide focused, immediate control for specific areas or equipment. Assessing factors like response time, communication needs, and system integration ensures optimal performance and safety.

Central Control Room vs Local Control Room Infographic

libmatt.com

libmatt.com