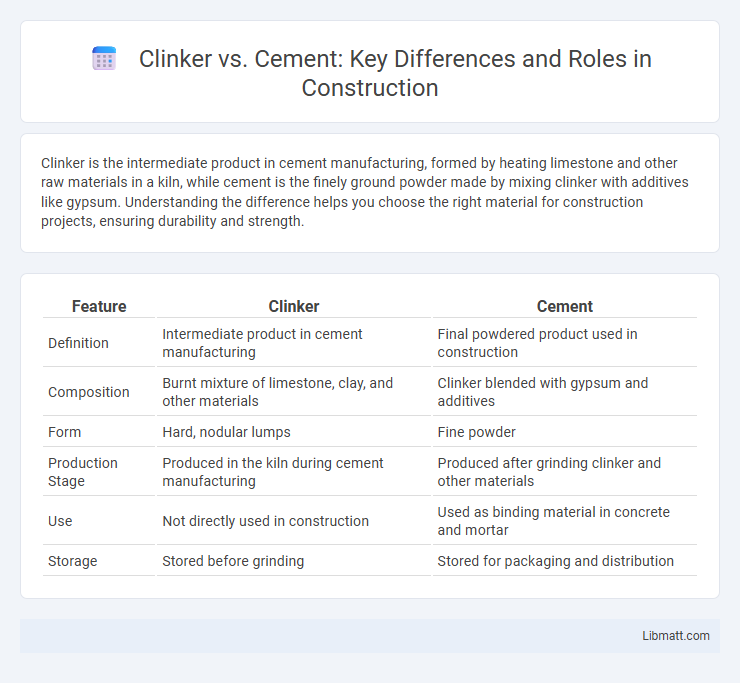

Clinker is the intermediate product in cement manufacturing, formed by heating limestone and other raw materials in a kiln, while cement is the finely ground powder made by mixing clinker with additives like gypsum. Understanding the difference helps you choose the right material for construction projects, ensuring durability and strength.

Table of Comparison

| Feature | Clinker | Cement |

|---|---|---|

| Definition | Intermediate product in cement manufacturing | Final powdered product used in construction |

| Composition | Burnt mixture of limestone, clay, and other materials | Clinker blended with gypsum and additives |

| Form | Hard, nodular lumps | Fine powder |

| Production Stage | Produced in the kiln during cement manufacturing | Produced after grinding clinker and other materials |

| Use | Not directly used in construction | Used as binding material in concrete and mortar |

| Storage | Stored before grinding | Stored for packaging and distribution |

Introduction to Clinker and Cement

Clinker is a solid material produced by sintering limestone and other raw materials in a kiln at high temperatures, serving as the primary ingredient in cement production. Cement is a finely ground powder that combines clinker with additives such as gypsum to control setting time and improve performance in construction applications. Understanding the differences between clinker and cement helps you evaluate cement quality and its suitability for specific building projects.

What is Clinker?

Clinker is a nodular material produced in the kiln during the cement manufacturing process and serves as the primary ingredient in cement. It consists mainly of calcium silicates formed by heating limestone and clay at high temperatures, typically around 1450degC. The clinker is then ground into a fine powder and mixed with gypsum to create ordinary Portland cement, which is essential for concrete production.

What is Cement?

Cement is a finely ground powder made primarily from clinker, gypsum, and other additives that act as a binder when mixed with water, sand, and aggregates to form concrete. Clinker consists of lumps produced by heating limestone and other materials in a kiln, which are then ground to produce cement. Your construction projects depend on the correct use of cement to ensure strength, durability, and structural integrity.

Production Process: Clinker vs Cement

Clinker is produced by heating limestone and other raw materials in a rotary kiln at temperatures around 1450degC, resulting in nodules of reactive material. Cement is then created by grinding clinker with gypsum and other additives to achieve the final fine powder consistency. The production process differentiates clinker as the intermediate product, while cement is the finished material used in construction.

Key Chemical Composition Differences

Clinker primarily consists of calcium silicates, notably tricalcium silicate (C3S) and dicalcium silicate (C2S), which are responsible for strength development in cement. Cement contains clinker particles combined with additives like gypsum to control setting time and other minerals that influence durability and workability. Understanding these key chemical composition differences helps optimize Your concrete mix design for performance and longevity.

Physical Properties: Clinker vs Cement

Clinker exhibits a rough, nodular texture with high hardness and is the intermediate product formed after the calcination of raw materials in cement production, whereas cement is a fine, powdery substance resulting from grinding clinker with gypsum and other additives. The particle size of cement is significantly smaller than clinker, which enhances its reactivity and allows for easier mixing with water to form a workable paste. Your choice between clinker and cement impacts the final strength, setting time, and durability of concrete, given the distinct physical characteristics of each material.

Uses and Applications

Clinker serves as the primary raw material in the production of cement, influencing the strength and durability of the final product used in construction. Cement, made by grinding clinker with gypsum and other additives, is essential for creating concrete, mortar, and grout, widely applied in building foundations, infrastructure projects, and road construction. The choice between clinker and cement depends on the stage of the manufacturing process and the specific requirements of construction applications.

Environmental Impact Comparison

Clinker production generates significantly higher CO2 emissions compared to cement, primarily due to the calcination process and fossil fuel consumption in kilns. Cement mixes clinker with additives like gypsum or fly ash, which can reduce overall carbon footprint by lowering clinker content per ton of cement produced. Innovations in alternative binders and supplementary cementitious materials contribute to reducing the environmental impact of cement manufacturing, promoting more sustainable construction materials.

Cost and Economic Considerations

Clinker production incurs higher energy costs due to the intensive calcination process, increasing overall cement manufacturing expenses. Cement, being a mixture of clinker and other additives like gypsum and slag, offers a cost-effective alternative by reducing clinker content, thus lowering production costs and environmental impact. Economically, optimizing clinker to cement ratios enhances profitability while meeting quality standards and regulatory requirements.

Conclusion: Choosing Between Clinker and Cement

Clinker serves as the primary component in cement production, where it is ground and mixed with additives to form cement. Selecting between clinker and cement depends largely on the application stage: clinker is ideal for manufacturers aiming to produce custom cement blends, while cement is suited for direct construction use. Understanding the specific project requirements and processing capabilities ensures optimal material choice for enhanced structural performance and durability.

Clinker vs Cement Infographic

libmatt.com

libmatt.com