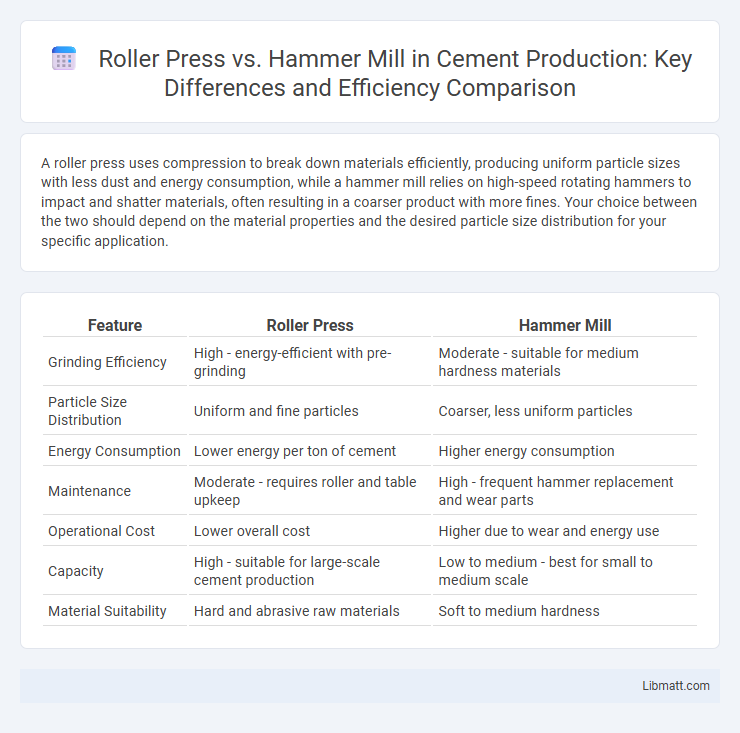

A roller press uses compression to break down materials efficiently, producing uniform particle sizes with less dust and energy consumption, while a hammer mill relies on high-speed rotating hammers to impact and shatter materials, often resulting in a coarser product with more fines. Your choice between the two should depend on the material properties and the desired particle size distribution for your specific application.

Table of Comparison

| Feature | Roller Press | Hammer Mill |

|---|---|---|

| Grinding Efficiency | High - energy-efficient with pre-grinding | Moderate - suitable for medium hardness materials |

| Particle Size Distribution | Uniform and fine particles | Coarser, less uniform particles |

| Energy Consumption | Lower energy per ton of cement | Higher energy consumption |

| Maintenance | Moderate - requires roller and table upkeep | High - frequent hammer replacement and wear parts |

| Operational Cost | Lower overall cost | Higher due to wear and energy use |

| Capacity | High - suitable for large-scale cement production | Low to medium - best for small to medium scale |

| Material Suitability | Hard and abrasive raw materials | Soft to medium hardness |

Introduction to Roller Press and Hammer Mill

Roller Press and Hammer Mill are essential grinding machines used in various industries for size reduction of materials. Roller Press utilizes pressure between rotating rollers to crush materials, providing energy-efficient and uniform particle size output. Hammer Mill employs high-speed rotating hammers that impact and shatter material, making it ideal for coarse grinding of fibrous or abrasive substances.

Core Principles of Size Reduction

Roller presses reduce particle size by compressing materials between two rotating rolls, applying shear and compressive forces for efficient grinding. Hammer mills utilize high-speed rotating hammers to impact and shatter particles through repeated collisions, producing a finer and more uniform output. Both methods rely on mechanical energy but differ fundamentally in force application and material processing dynamics.

Structural Design Comparison

The roller press features two counter-rotating cylinders designed for compressive grinding, providing high pressure and energy efficiency with minimal particle size variation. The hammer mill utilizes swinging hammers attached to a rotating shaft, generating impact force to shatter materials, resulting in a more versatile particle size distribution but higher energy consumption. Structurally, the roller press's compact, heavy-duty frame supports consistent grinding pressure, while the hammer mill's open design facilitates easier maintenance and operation with variable feedstock.

Energy Efficiency Analysis

Roller presses offer higher energy efficiency compared to hammer mills by applying compressive force instead of impact, resulting in lower power consumption per ton of material processed. You can reduce operational costs significantly by choosing a roller press, as it generates less heat and minimizes material degradation. Studies show energy savings of up to 30-50% favor roller press systems over traditional hammer mills in crushing and grinding applications.

Product Fineness and Particle Size Control

Roller Press machines deliver superior product fineness with more uniform particle size distribution compared to Hammer Mills, which often produce coarser and irregular particles. The precise gap adjustment and roller pressure in a Roller Press allow for better control over particle size, enhancing the quality of your final product. For applications requiring consistent fine particles, a Roller Press offers significant advantages over the impact-based grinding of Hammer Mills.

Maintenance Requirements and Costs

Roller presses require less maintenance due to fewer moving parts and lower wear rates compared to hammer mills, resulting in reduced downtime and lower overall maintenance costs. Hammer mills experience higher wear on hammers, screens, and liners, demanding frequent replacements and more intensive labor. Cost analysis shows roller presses offer long-term savings despite higher initial investment, making them economically advantageous for continuous, high-volume operations.

Throughput and Capacity Evaluation

Roller presses typically offer higher throughput and greater capacity compared to hammer mills, making them suitable for large-scale industrial applications where consistent particle size and energy efficiency are critical. Hammer mills may have lower throughput due to their design and can require more frequent maintenance to handle high-capacity demands. Evaluating your specific processing requirements will help determine if the roller press's enhanced capacity aligns better with your production goals.

Suitable Materials and Feed Characteristics

Roller presses excel at grinding hard, abrasive materials like limestone, clinker, and cement raw mix, offering uniform particle size and energy efficiency. Hammer mills handle softer or fibrous materials such as wood chips, grains, and biomass, accommodating higher moisture content and providing coarse to medium grind. Understanding your feed's hardness, moisture, and particle size will help select the ideal milling equipment for optimal processing performance.

Environmental and Noise Considerations

Roller presses generate less noise and produce fewer dust emissions compared to hammer mills, making them more environmentally friendly for industrial applications. Hammer mills tend to create higher levels of airborne particulate matter and significant noise pollution, which can impact worker health and require extensive noise control measures. If reducing your operation's environmental footprint and maintaining a quieter workspace are priorities, a roller press offers clear advantages.

Application Scenarios: Choosing the Right Equipment

Roller presses excel in grinding abrasive materials and processing raw minerals with high moisture content, making them ideal for cement and mining industries. Hammer mills are preferred for pulverizing softer materials such as biomass, agricultural waste, and limestone due to their ability to achieve finer particle sizes. Selecting the right equipment depends on material hardness, moisture level, and desired output size to optimize operational efficiency and product quality.

Roller Press vs Hammer Mill Infographic

libmatt.com

libmatt.com