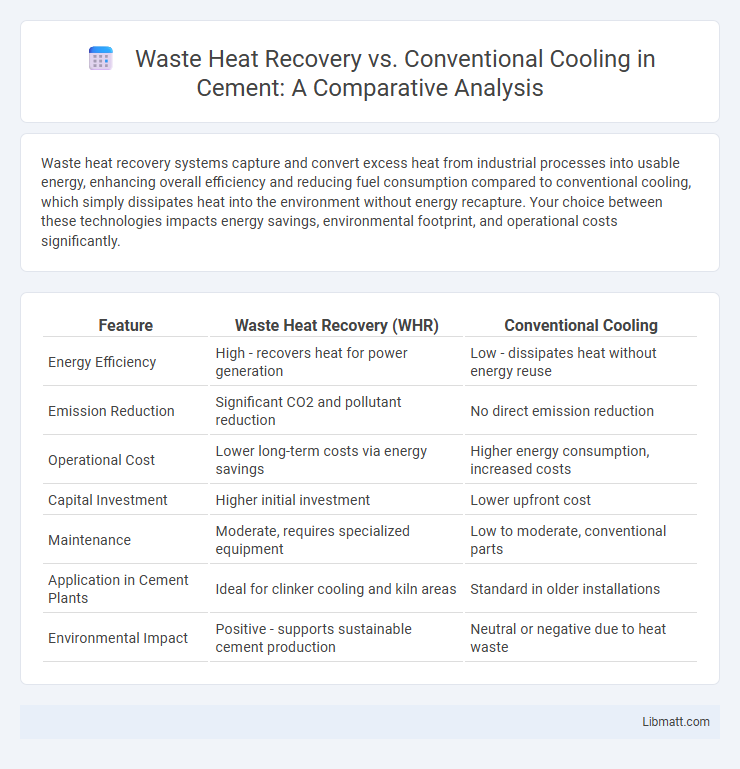

Waste heat recovery systems capture and convert excess heat from industrial processes into usable energy, enhancing overall efficiency and reducing fuel consumption compared to conventional cooling, which simply dissipates heat into the environment without energy recapture. Your choice between these technologies impacts energy savings, environmental footprint, and operational costs significantly.

Table of Comparison

| Feature | Waste Heat Recovery (WHR) | Conventional Cooling |

|---|---|---|

| Energy Efficiency | High - recovers heat for power generation | Low - dissipates heat without energy reuse |

| Emission Reduction | Significant CO2 and pollutant reduction | No direct emission reduction |

| Operational Cost | Lower long-term costs via energy savings | Higher energy consumption, increased costs |

| Capital Investment | Higher initial investment | Lower upfront cost |

| Maintenance | Moderate, requires specialized equipment | Low to moderate, conventional parts |

| Application in Cement Plants | Ideal for clinker cooling and kiln areas | Standard in older installations |

| Environmental Impact | Positive - supports sustainable cement production | Neutral or negative due to heat waste |

Introduction to Waste Heat Recovery and Conventional Cooling

Waste heat recovery captures and repurposes excess thermal energy from industrial processes to improve energy efficiency and reduce fuel consumption. Conventional cooling systems, such as vapor-compression chillers, rely on external energy input to remove heat and maintain temperature control but often waste excess heat to the environment. Integrating waste heat recovery with cooling processes can significantly lower operational costs and reduce greenhouse gas emissions compared to traditional cooling methods.

Principles of Waste Heat Recovery Systems

Waste heat recovery systems capture and reuse excess thermal energy generated by industrial processes, converting it into useful forms like electricity or heating, thereby enhancing energy efficiency. Conventional cooling methods dissipate heat to the environment using air or water-based cooling systems but do not reclaim energy for reuse. Waste heat recovery relies on components such as heat exchangers, thermoelectric generators, or absorption chillers to transform waste heat into valuable output, significantly reducing operational costs and environmental impact.

Conventional Cooling Methods Explained

Conventional cooling methods primarily rely on vapor compression and absorption systems to manage heat dissipation in industrial and commercial applications. These systems consume significant energy by using refrigeration cycles that transfer heat from one area to another, often leading to increased operational costs. Understanding how your current cooling setup operates is essential when considering more energy-efficient alternatives like waste heat recovery.

Energy Efficiency Comparison

Waste heat recovery systems significantly improve energy efficiency by capturing and reusing excess thermal energy that conventional cooling systems typically lose. While standard cooling methods rely heavily on electricity to remove heat, waste heat recovery reduces operational costs by converting waste heat into usable power or preheating fluids, thereby lowering overall energy consumption. Your facility can achieve substantial energy savings and reduced carbon emissions by integrating waste heat recovery technologies in place of traditional cooling approaches.

Environmental Impact Assessment

Waste heat recovery systems significantly reduce greenhouse gas emissions by capturing and reusing thermal energy that would otherwise be lost, lowering the demand for fossil fuel-based energy sources. Conventional cooling methods often rely on electricity from non-renewable resources and use refrigerants that can contribute to ozone depletion and global warming. Environmental impact assessments show that integrating waste heat recovery can lead to decreased carbon footprints, reduced energy consumption, and improved sustainability compared to traditional cooling technologies.

Cost Implications and ROI

Waste Heat Recovery (WHR) systems often require higher upfront investment compared to Conventional Cooling due to advanced technology and integration costs, but they significantly reduce energy expenses by utilizing waste heat for power generation or preheating. Conventional Cooling systems may have lower initial costs but incur higher operational costs due to continuous energy consumption, impacting long-term savings. Evaluating Your ROI favors WHR when energy prices are high or sustainability incentives apply, as the payback period shortens through improved efficiency and reduced utility bills.

Technological Challenges and Solutions

Waste heat recovery systems face technological challenges such as low-temperature heat capture efficiency and integration complexities with existing conventional cooling infrastructure. Advanced heat exchangers and hybrid absorption-compression cooling technologies address these inefficiencies by enhancing thermal energy utilization and reducing operational costs. Understanding these solutions can help you optimize energy savings while overcoming barriers posed by conventional cooling methods.

Industry Applications: Waste Heat Recovery vs Conventional Cooling

Waste heat recovery systems capture and reuse energy from industrial processes, significantly reducing operational costs and lowering carbon emissions compared to conventional cooling methods that primarily dissipate heat into the environment. Industries such as steel manufacturing, chemical plants, and power generation benefit from integrating waste heat recovery by enhancing energy efficiency and minimizing reliance on external energy sources. Conventional cooling remains prevalent for maintaining equipment temperatures, but waste heat recovery offers a sustainable, economically advantageous alternative by converting excess heat into usable energy.

Future Trends in Cooling and Heat Recovery

Future trends in cooling and heat recovery emphasize integrating waste heat recovery systems with advanced conventional cooling technologies to enhance energy efficiency and reduce carbon emissions. Innovations like adsorption chillers, thermoelectric generators, and combined heat and power (CHP) systems are driving the shift towards sustainable thermal management solutions. Your facility can benefit from adopting these cutting-edge technologies, optimizing energy use while supporting environmental goals.

Conclusion: Choosing the Right Solution

Choosing the right solution between waste heat recovery and conventional cooling depends on your specific operational goals and energy efficiency priorities. Waste heat recovery systems optimize energy use by capturing and reusing residual heat, significantly reducing fuel consumption and emissions. Your decision should consider long-term cost savings, environmental impact, and the compatibility of each system with your existing infrastructure.

Waste Heat Recovery vs Conventional Cooling Infographic

libmatt.com

libmatt.com