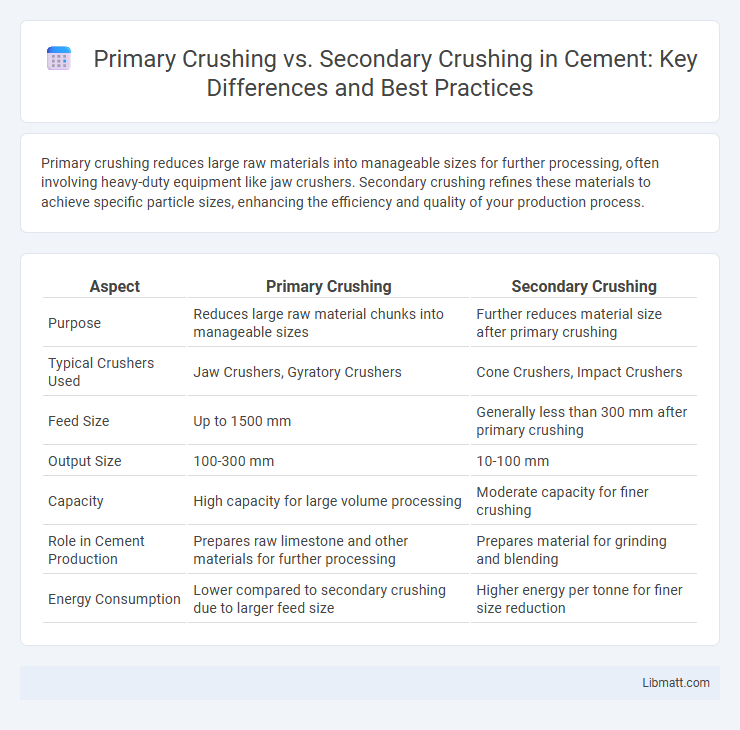

Primary crushing reduces large raw materials into manageable sizes for further processing, often involving heavy-duty equipment like jaw crushers. Secondary crushing refines these materials to achieve specific particle sizes, enhancing the efficiency and quality of your production process.

Table of Comparison

| Aspect | Primary Crushing | Secondary Crushing |

|---|---|---|

| Purpose | Reduces large raw material chunks into manageable sizes | Further reduces material size after primary crushing |

| Typical Crushers Used | Jaw Crushers, Gyratory Crushers | Cone Crushers, Impact Crushers |

| Feed Size | Up to 1500 mm | Generally less than 300 mm after primary crushing |

| Output Size | 100-300 mm | 10-100 mm |

| Capacity | High capacity for large volume processing | Moderate capacity for finer crushing |

| Role in Cement Production | Prepares raw limestone and other materials for further processing | Prepares material for grinding and blending |

| Energy Consumption | Lower compared to secondary crushing due to larger feed size | Higher energy per tonne for finer size reduction |

Overview of Primary and Secondary Crushing

Primary crushing involves the initial size reduction of raw materials using heavy-duty crushers such as jaw crushers or gyratory crushers, designed to handle large, bulky rocks directly from the mine. Secondary crushing follows, utilizing cone crushers or impact crushers to further reduce material size and prepare it for finer processing stages or direct use in production. Efficient integration of primary and secondary crushing optimizes material flow, enhances overall plant productivity, and ensures consistent output quality.

Definition of Primary Crushing

Primary crushing involves the initial stage of reducing large rocks or ore into smaller, manageable sizes for further processing or handling. This process typically employs heavy-duty equipment like jaw crushers or gyratory crushers to break down raw materials directly extracted from the mine. Your choice of primary crushing method impacts efficiency and prepares material adequately for secondary crushing stages.

Definition of Secondary Crushing

Secondary crushing refers to the process of reducing the size of material after primary crushing, typically involving crushers such as cone crushers, impact crushers, or hammer mills that further break down the output from primary crushers. This stage produces smaller, more uniform aggregate particles suitable for specific construction or industrial applications. Secondary crushers improve material gradation and efficiency in downstream processes compared to primary crushing.

Key Differences Between Primary and Secondary Crushing

Primary crushing involves the initial reduction of large, raw materials into smaller, manageable sizes, typically using jaw or gyratory crushers designed for high capacity and larger feed sizes. Secondary crushing further reduces the size of these materials using cone or impact crushers to achieve more precise particle sizes and improved product shape. Your choice between primary and secondary crushing depends on the desired output size, material type, and overall processing requirements.

Typical Equipment Used in Primary Crushing

Primary crushing typically involves large, heavy-duty machines such as jaw crushers, gyratory crushers, or impact crushers designed for handling large feed sizes and high capacity. These crushers break down raw materials into manageable chunks, preparing them for secondary crushing or further processing. Your choice of primary crushing equipment depends on the material hardness, feed size, and production requirements to optimize efficiency.

Typical Equipment Used in Secondary Crushing

Secondary crushing typically utilizes cone crushers, impact crushers, and hammer crushers designed to handle smaller feed sizes and produce finer output materials. Cone crushers are favored for their high capacity and ability to crush hard, abrasive rocks, while impact crushers excel in reducing softer materials with a high reduction ratio. Hammer crushers offer rapid material breakage with impact force, making them suitable for limestone and other similar applications in secondary crushing stages.

Applications of Primary Crushing

Primary crushing is essential for reducing large raw materials into manageable sizes for further processing in mining, quarrying, and construction industries. It is typically applied at the beginning of material handling processes, where equipment like jaw crushers and gyratory crushers handle large, tough rock to ensure optimal efficiency in subsequent crushing stages. Your operation benefits from primary crushing by significantly lowering material size and preparing it for secondary crushing, improving overall throughput and equipment longevity.

Applications of Secondary Crushing

Secondary crushing is primarily used to reduce the size of materials after primary crushing in mining, quarrying, and construction industries. It is essential for processing aggregates, mineral ores, and recycled materials to meet precise size and product specifications for further handling or final use. Secondary crushers like cone crushers, impact crushers, and hammer mills enhance product uniformity and improve the efficiency of downstream operations.

Advantages and Limitations of Primary and Secondary Crushing

Primary crushing offers the advantage of handling large, bulky raw materials efficiently, reducing them into manageable size for further processing, which is essential for protecting downstream equipment. However, its limitations include less precision and a generally coarser output compared to secondary crushing, making it unsuitable for ready-for-use materials. Secondary crushing provides finer material with improved product shape and size uniformity, enhancing your overall processing efficiency, but it requires materials already reduced by primary crushers, potentially increasing operational complexity and costs.

Choosing the Right Crushing Stage for Your Operation

Choosing the right crushing stage depends on the hardness and size of the material as well as your required output size. Primary crushing handles large, raw materials to reduce them into manageable sizes for secondary crushing, which further refines the product for processing or final use. Optimizing both primary and secondary crushing stages improves efficiency, reduces operational costs, and ensures consistent material quality for your operation.

Primary Crushing vs Secondary Crushing Infographic

libmatt.com

libmatt.com