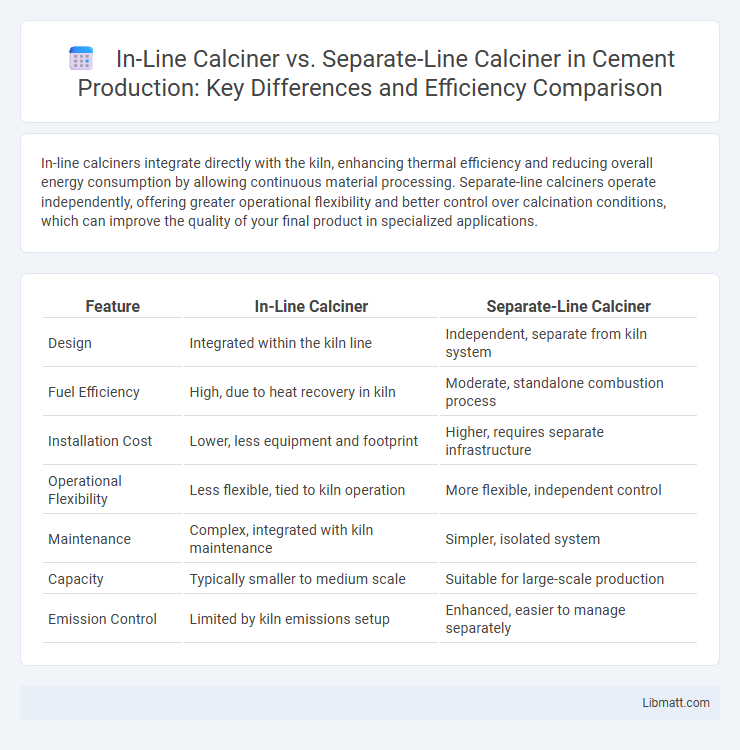

In-line calciners integrate directly with the kiln, enhancing thermal efficiency and reducing overall energy consumption by allowing continuous material processing. Separate-line calciners operate independently, offering greater operational flexibility and better control over calcination conditions, which can improve the quality of your final product in specialized applications.

Table of Comparison

| Feature | In-Line Calciner | Separate-Line Calciner |

|---|---|---|

| Design | Integrated within the kiln line | Independent, separate from kiln system |

| Fuel Efficiency | High, due to heat recovery in kiln | Moderate, standalone combustion process |

| Installation Cost | Lower, less equipment and footprint | Higher, requires separate infrastructure |

| Operational Flexibility | Less flexible, tied to kiln operation | More flexible, independent control |

| Maintenance | Complex, integrated with kiln maintenance | Simpler, isolated system |

| Capacity | Typically smaller to medium scale | Suitable for large-scale production |

| Emission Control | Limited by kiln emissions setup | Enhanced, easier to manage separately |

Introduction to Calciners in Cement Production

Calciners play a critical role in cement production by heating raw materials to initiate the chemical decomposition of calcium carbonate into calcium oxide and carbon dioxide, a process essential for clinker formation. In-line calciners are integrated directly within the kiln system, enhancing energy efficiency and reducing thermal losses, while separate-line calciners operate independently, allowing for flexibility in processing capacity and maintenance. Your choice between in-line and separate-line calciners impacts the overall thermal efficiency, operational control, and integration within the cement manufacturing process.

Overview of In-Line Calciner Technology

In-Line Calciner technology integrates the calcination process directly within the cement kiln system, enhancing thermal efficiency and reducing fuel consumption. This method allows for precise control of temperature and residence time, improving clinker quality while minimizing emissions. Your plant can benefit from streamlined operations and lower operational costs by adopting In-Line Calciner systems over Separate-Line alternatives.

Overview of Separate-Line Calciner Technology

Separate-line calciner technology uses an independent calcining unit apart from the preheater tower, allowing precise temperature control and improved fuel efficiency in cement production. This system enhances clinker quality by minimizing gas contamination and offers flexibility to process various raw meal compositions. Your plant can benefit from reduced operational costs and easier maintenance due to the modular design of the separate-line calciner.

Key Differences Between In-Line and Separate-Line Calciners

In-line calciners integrate directly with the kiln system, enhancing heat recovery and reducing overall fuel consumption, whereas separate-line calciners operate independently, offering more operational flexibility but often requiring higher energy input. In-line calciners typically provide better control over clinker quality due to synchronous processing, while separate-line calciners allow for easier maintenance and process adjustments without impacting the kiln. The choice between in-line and separate-line calciners significantly affects cement plant efficiency, emissions, and production costs.

Energy Efficiency Comparison

In-line calciners integrate the calcination process within the kiln system, significantly reducing energy consumption by utilizing the kiln's existing heat, whereas separate-line calciners require independent fuel sources, leading to higher overall energy use. You benefit from enhanced energy efficiency with in-line calciners through optimized heat recovery and reduced thermal losses compared to the standalone separate-line configuration. This makes in-line calciners a more sustainable choice for minimizing fuel costs and carbon emissions in cement production.

Impact on Emissions and Sustainability

In-line calciners integrate the calcination process directly within the kiln system, significantly reducing CO2 emissions by minimizing fuel consumption and heat loss compared to separate-line calciners. Separate-line calciners operate independently, allowing better control over calcination parameters but often resulting in higher energy usage and increased emissions due to additional heating requirements. Your choice between these systems directly affects sustainability, with in-line calciners generally offering lower environmental impact through improved thermal efficiency and reduced greenhouse gas output.

Operational Flexibility and Process Control

In-line calciners offer superior operational flexibility by integrating directly with the kiln process, enabling real-time temperature adjustments and consistent material throughput, which enhances process control precision. Separate-line calciners provide independent control over the calcination environment, allowing for optimized thermal treatment and better handling of varying feedstock compositions, thus improving overall process stability. The choice between the two impacts the ability to adapt to operational changes and maintain product quality, with in-line systems favoring seamless integration and separate-line configurations supporting specialized process adjustments.

Investment and Maintenance Considerations

In-line calciners typically require a lower initial investment due to their integrated design, reducing the need for extensive auxiliary equipment and space. Separate-line calciners often demand higher maintenance costs because of their complexity and additional transport systems between calciner and kiln, leading to increased wear and potential downtime. Your choice should weigh the balance between upfront capital savings of in-line calciners and the potentially higher long-term maintenance expenses associated with separate-line systems.

Industrial Case Studies and Performance Data

Industrial case studies comparing In-Line Calciners and Separate-Line Calciners reveal significant differences in energy efficiency and product quality, with In-Line Calciners often demonstrating up to 15% lower fuel consumption due to integrated heat recovery. Performance data from cement plants indicate that Separate-Line Calciners provide greater operational flexibility, allowing independent control of calcination and kiln processes, which can improve clinker quality under variable feed conditions. Case studies also highlight that plants utilizing In-Line Calciners report reduced capital costs and maintenance requirements, contributing to overall improved operational economics.

Choosing the Right Calciner for Your Plant

Choosing the right calciner for your plant depends on factors such as operational efficiency, maintenance requirements, and space constraints. In-line calciners integrate directly with the kiln system, offering better heat recovery and streamlined operation, while separate-line calciners allow for more flexible control and ease of maintenance. Your decision should weigh the benefits of energy savings and simplified processes against the potential advantages of operational flexibility and reduced downtime.

In-Line Calciner vs Separate-Line Calciner Infographic

libmatt.com

libmatt.com