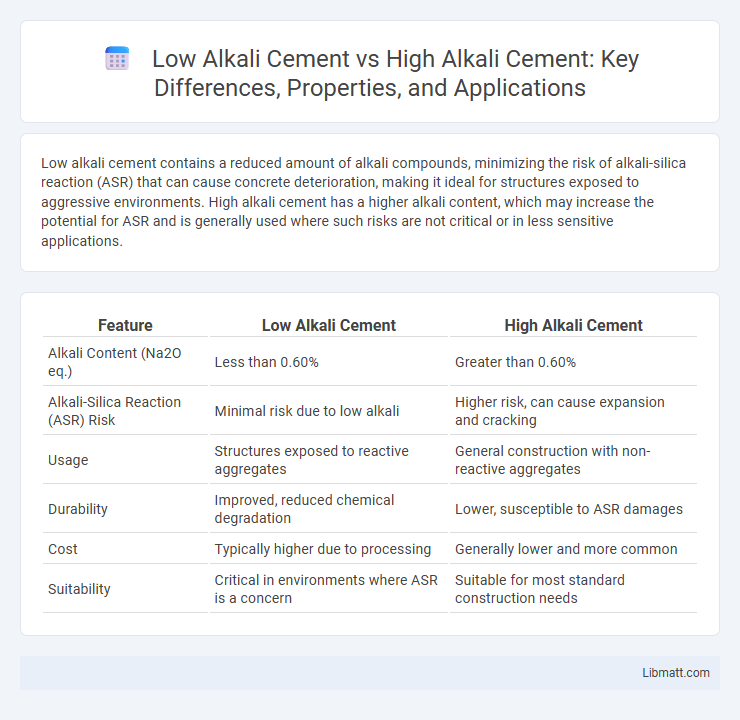

Low alkali cement contains a reduced amount of alkali compounds, minimizing the risk of alkali-silica reaction (ASR) that can cause concrete deterioration, making it ideal for structures exposed to aggressive environments. High alkali cement has a higher alkali content, which may increase the potential for ASR and is generally used where such risks are not critical or in less sensitive applications.

Table of Comparison

| Feature | Low Alkali Cement | High Alkali Cement |

|---|---|---|

| Alkali Content (Na2O eq.) | Less than 0.60% | Greater than 0.60% |

| Alkali-Silica Reaction (ASR) Risk | Minimal risk due to low alkali | Higher risk, can cause expansion and cracking |

| Usage | Structures exposed to reactive aggregates | General construction with non-reactive aggregates |

| Durability | Improved, reduced chemical degradation | Lower, susceptible to ASR damages |

| Cost | Typically higher due to processing | Generally lower and more common |

| Suitability | Critical in environments where ASR is a concern | Suitable for most standard construction needs |

Introduction to Alkali Content in Cement

Alkali content in cement primarily refers to the concentration of sodium oxide (Na2O) and potassium oxide (K2O) expressed as Na2O equivalent, which significantly influences cement's chemical properties and durability. Low alkali cement typically contains less than 0.6% Na2O equivalent, reducing the risk of alkali-silica reaction (ASR) and enhancing long-term structural integrity, especially in concrete exposed to reactive aggregates. High alkali cement, with greater than 0.6% Na2O equivalent, may accelerate early strength development but poses higher susceptibility to ASR, leading to potential expansion and cracking in concrete.

Defining Low Alkali Cement

Low alkali cement contains less than 0.60% equivalent sodium oxide (Na2O) and potassium oxide (K2O), reducing the risk of alkali-silica reaction (ASR) in concrete structures. This cement type is preferred in environments prone to ASR, as it limits expansive reactions between alkalis and reactive silica in aggregates. High alkali cement exceeds this alkali content threshold, increasing the potential for durability issues in concrete due to internal chemical reactions.

Defining High Alkali Cement

High alkali cement contains a higher concentration of alkalis, typically sodium oxide (Na2O) and potassium oxide (K2O), exceeding 0.6% by weight, which can trigger alkali-silica reaction (ASR) in concrete. This type of cement is more reactive with certain aggregates, potentially leading to expansion and cracking over time. You should select low alkali cement when durability and resistance to ASR are critical for your construction project.

Chemical Composition Differences

Low alkali cement contains less than 0.6% equivalent sodium oxide (Na2O) and potassium oxide (K2O), reducing the risk of alkali-silica reaction (ASR) in concrete. High alkali cement typically has alkali content above 0.6%, which can promote ASR by reacting with silica in aggregates, leading to expansion and cracking. The primary chemical difference lies in the total alkali content, directly influencing durability and performance in concrete structures.

Impact on Concrete Durability

Low alkali cement minimizes the risk of alkali-silica reaction (ASR), enhancing the long-term durability of concrete by reducing internal expansion and cracking. High alkali cement increases the availability of alkalis, which can react with reactive aggregates leading to ASR-induced deterioration and compromised structural integrity. Concrete made with low alkali cement demonstrates improved resistance to moisture ingress, chemical attack, and freeze-thaw cycles, thereby extending its service life in aggressive environments.

Effects on Alkali-Silica Reaction (ASR)

Low alkali cement significantly reduces the risk of Alkali-Silica Reaction (ASR) by limiting the availability of alkalis that react with silica in aggregates, thereby enhancing concrete durability and minimizing expansion and cracking. High alkali cement increases the potential for ASR due to its elevated alkali content, which accelerates the formation of expansive gel in reactive aggregates, leading to severe structural damage over time. Using low alkali cement is a critical strategy in ASR-prone environments to control microcracking and extend the lifespan of concrete structures.

Suitability for Different Construction Environments

Low alkali cement is ideal for construction environments where minimizing alkali-silica reaction (ASR) is critical, such as in concrete exposed to moisture or sulfate-rich soils. High alkali cement may be suitable for dry, controlled environments but poses risks of durability issues in aggressive conditions. Your choice between the two should consider the chemical exposure and long-term performance requirements of the specific construction site.

Influence on Setting Time and Workability

Low alkali cement typically offers improved setting time stability and enhanced workability by reducing the risk of alkali-silica reaction, which can cause expansion and cracking. High alkali cement may accelerate setting time but can lead to diminished workability and long-term durability issues due to increased chemical activity. Your choice between the two cements should consider project requirements for setting performance and desired workability characteristics.

Cost and Availability Considerations

Low alkali cement generally incurs higher production costs due to specialized raw materials and stricter quality control processes compared to high alkali cement. High alkali cement is more widely available and cost-effective, benefiting from mass production and standard raw materials, making it a preferred choice for budget-sensitive construction projects. The choice between the two often hinges on balancing upfront cost savings against potential long-term durability concerns related to alkali-silica reactions.

Conclusion: Selecting the Right Cement Type

Choosing between low alkali cement and high alkali cement depends on the specific requirements of your construction project, such as durability and resistance to alkali-silica reaction (ASR). Low alkali cement is ideal for structures exposed to reactive aggregates or aggressive environments, reducing the risk of cracking and long-term damage. High alkali cement may be suitable for general applications where ASR is not a concern, offering cost-effectiveness and standard performance.

Low alkali cement vs High alkali cement Infographic

libmatt.com

libmatt.com