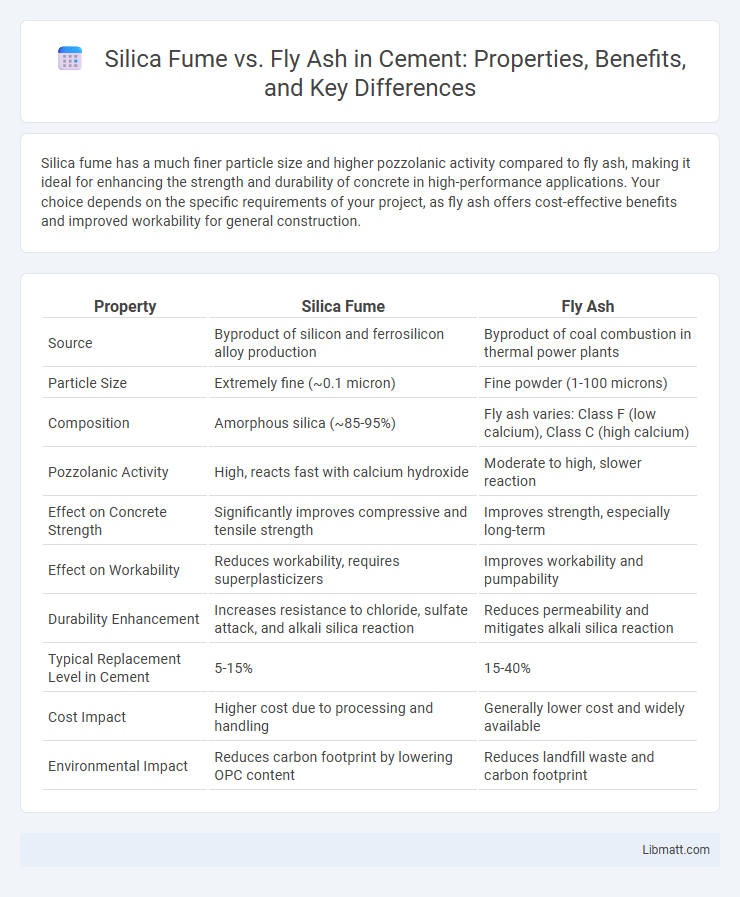

Silica fume has a much finer particle size and higher pozzolanic activity compared to fly ash, making it ideal for enhancing the strength and durability of concrete in high-performance applications. Your choice depends on the specific requirements of your project, as fly ash offers cost-effective benefits and improved workability for general construction.

Table of Comparison

| Property | Silica Fume | Fly Ash |

|---|---|---|

| Source | Byproduct of silicon and ferrosilicon alloy production | Byproduct of coal combustion in thermal power plants |

| Particle Size | Extremely fine (~0.1 micron) | Fine powder (1-100 microns) |

| Composition | Amorphous silica (~85-95%) | Fly ash varies: Class F (low calcium), Class C (high calcium) |

| Pozzolanic Activity | High, reacts fast with calcium hydroxide | Moderate to high, slower reaction |

| Effect on Concrete Strength | Significantly improves compressive and tensile strength | Improves strength, especially long-term |

| Effect on Workability | Reduces workability, requires superplasticizers | Improves workability and pumpability |

| Durability Enhancement | Increases resistance to chloride, sulfate attack, and alkali silica reaction | Reduces permeability and mitigates alkali silica reaction |

| Typical Replacement Level in Cement | 5-15% | 15-40% |

| Cost Impact | Higher cost due to processing and handling | Generally lower cost and widely available |

| Environmental Impact | Reduces carbon footprint by lowering OPC content | Reduces landfill waste and carbon footprint |

Introduction to Silica Fume and Fly Ash

Silica fume is an ultrafine byproduct of silicon metal or ferrosilicon alloy production, known for its high silica content and pozzolanic properties, which enhance concrete strength and durability. Fly ash, a residue from coal combustion in power plants, contains spherical particles rich in silica and alumina that improve workability and long-term strength of concrete. Both materials play crucial roles as supplementary cementitious materials in sustainable construction, reducing cement usage and environmental impact.

Chemical Composition Comparison

Silica fume contains over 85% amorphous silicon dioxide (SiO2), making it highly reactive in pozzolanic reactions, while fly ash typically has 40-60% silica along with significant alumina (Al2O3) and iron oxide (Fe2O3) content. The high silica content in silica fume enhances your concrete's strength and durability by producing additional calcium silicate hydrate (C-S-H) gel. Fly ash's diverse chemical makeup contributes to workability and long-term strength gain but offers lower early-age strength compared to silica fume.

Physical Properties and Particle Size

Silica fume consists of ultrafine spherical particles with an average diameter of about 0.1 to 0.2 microns, significantly smaller than fly ash particles which typically range from 1 to 150 microns and exhibit a more irregular shape. The high surface area of silica fume, approximately 20,000 m2/kg, enhances its pozzolanic reactivity compared to fly ash, whose surface area generally ranges from 300 to 600 m2/kg. These physical differences influence workability, water demand, and the microstructure development in concrete applications.

Production Processes and Sources

Silica fume is a byproduct of the high-temperature reduction of quartz in electric arc furnaces during silicon or ferrosilicon alloy production, resulting in an ultrafine powder rich in amorphous silicon dioxide. Fly ash is produced from the combustion of pulverized coal in thermal power plants, consisting mainly of spherical glassy particles with varying silica and alumina content depending on the coal source. Both materials serve as supplementary cementitious materials but originate from distinct industrial processes tied to metallurgy and energy production.

Effects on Concrete Strength and Durability

Silica fume significantly enhances concrete strength and durability by filling micro-pores and refining the microstructure, resulting in higher compressive strength and reduced permeability. Fly ash improves workability and long-term strength gain while reducing heat of hydration, contributing to enhanced durability and resistance to chemical attack. Your concrete mix can benefit from silica fume for rapid strength development and fly ash for improved durability and sustainability.

Workability and Setting Time Differences

Silica fume significantly reduces workability due to its fine particles and high surface area, which demand more water or superplasticizers to maintain slump, whereas fly ash improves workability by acting as a lubricant between cement particles. Setting time is shortened with silica fume because of its high pozzolanic reactivity, accelerating cement hydration, while fly ash typically delays setting time as it reacts slower than cement. These differences influence the choice of admixtures and mixing procedures in concrete production to achieve desired performance characteristics.

Environmental Impact and Sustainability

Silica fume significantly reduces carbon footprint by enhancing concrete durability and lowering cement demand, thus minimizing CO2 emissions. Fly ash, a coal combustion byproduct, contributes to waste reutilization and decreases landfill dependency, promoting sustainable construction practices. Both materials improve environmental sustainability by reducing raw material consumption and enhancing concrete performance.

Cost Considerations and Availability

Silica fume generally has a higher cost than fly ash due to its more complex production process and lower availability, often sourced as a byproduct of silicon and ferrosilicon alloy manufacturing. Fly ash is more widely available and cost-effective, especially in regions with abundant coal-fired power plants, making it a preferred choice for large-scale concrete projects. Your selection between silica fume and fly ash should consider both budget constraints and local supply to optimize project cost-efficiency and performance.

Applications in Modern Construction

Silica fume and fly ash are key supplementary cementitious materials used to enhance concrete performance in modern construction. Silica fume significantly improves concrete strength and durability, making it ideal for high-performance structures like bridges, tunnels, and high-rise buildings. Fly ash enhances workability and reduces permeability, often used in large-scale projects such as dams, pavements, and mass concrete pours, providing your construction with improved sustainability and long-term durability.

Choosing Between Silica Fume and Fly Ash

Choosing between silica fume and fly ash depends on the desired concrete properties: silica fume enhances strength and durability by significantly reducing permeability, making it ideal for high-performance concrete applications, while fly ash improves workability and reduces heat of hydration, beneficial for mass concrete and sustainability goals. Silica fume is more expensive and requires careful handling due to its fine particle size, whereas fly ash is more cost-effective and widely available from coal combustion byproducts. Consider project requirements such as exposure conditions, strength targets, and environmental impact when selecting the appropriate pozzolanic material.

Silica fume vs Fly ash Infographic

libmatt.com

libmatt.com