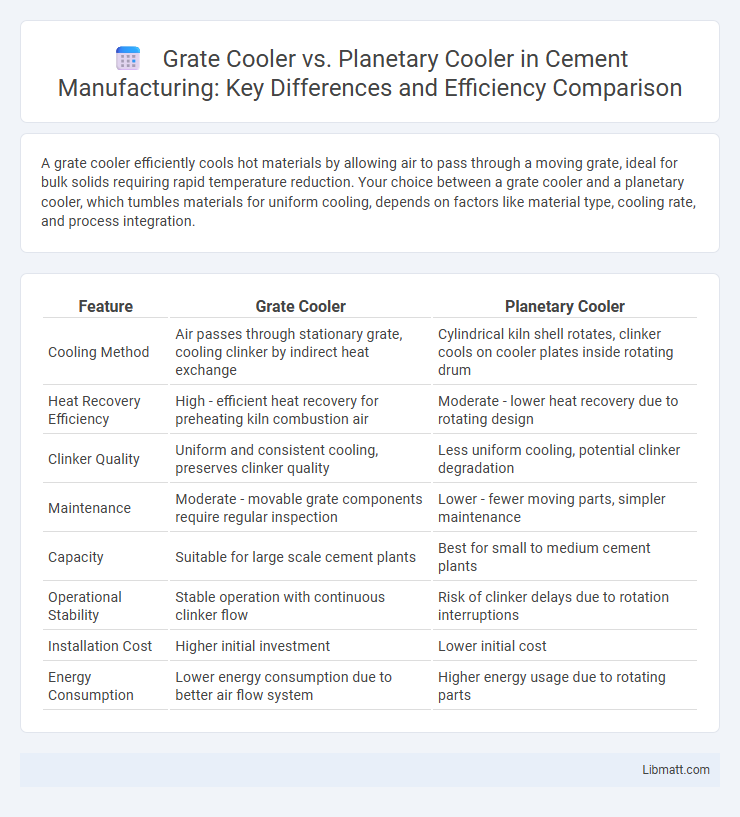

A grate cooler efficiently cools hot materials by allowing air to pass through a moving grate, ideal for bulk solids requiring rapid temperature reduction. Your choice between a grate cooler and a planetary cooler, which tumbles materials for uniform cooling, depends on factors like material type, cooling rate, and process integration.

Table of Comparison

| Feature | Grate Cooler | Planetary Cooler |

|---|---|---|

| Cooling Method | Air passes through stationary grate, cooling clinker by indirect heat exchange | Cylindrical kiln shell rotates, clinker cools on cooler plates inside rotating drum |

| Heat Recovery Efficiency | High - efficient heat recovery for preheating kiln combustion air | Moderate - lower heat recovery due to rotating design |

| Clinker Quality | Uniform and consistent cooling, preserves clinker quality | Less uniform cooling, potential clinker degradation |

| Maintenance | Moderate - movable grate components require regular inspection | Lower - fewer moving parts, simpler maintenance |

| Capacity | Suitable for large scale cement plants | Best for small to medium cement plants |

| Operational Stability | Stable operation with continuous clinker flow | Risk of clinker delays due to rotation interruptions |

| Installation Cost | Higher initial investment | Lower initial cost |

| Energy Consumption | Lower energy consumption due to better air flow system | Higher energy usage due to rotating parts |

Introduction to Clinker Cooling Systems

Clinker cooling systems play a crucial role in cement production by rapidly cooling clinker from around 1400degC to safer handling temperatures. Grate coolers use a perforated moving grate to allow air to pass through and cool the clinker efficiently, offering high heat recovery and energy savings. Planetary coolers rotate clinker in multiple tiers, providing compact design and gentle clinker handling, making your choice dependent on plant layout and specific process needs.

Overview of Grate Coolers

Grate coolers are widely used in the cement and metallurgy industries to recover heat from hot clinker or ore by passing the material over a series of moving grate plates while cooling air flows underneath. This technology enables efficient heat exchange, enhances energy recovery, and improves overall plant efficiency by preheating combustion air in the kiln or furnace process. Grate coolers feature robust mechanical design, high heat recovery rates, and adaptability to varying throughput capacities, distinguishing them from other cooling systems such as planetary coolers.

Overview of Planetary Coolers

Planetary coolers are thermodynamic devices designed to reduce the temperature of hot materials by transferring heat through a revolving cylindrical drum with internal flights, promoting efficient cooling and uniform material flow. Compared to grate coolers, which use a fixed grate bed with air passing through stationary material, planetary coolers offer enhanced thermal efficiency and compact design suitable for handling clinker in cement plants. Their rotating mechanism enables continuous cooling with reduced dust generation and maintenance requirements, improving overall plant operation.

Key Differences Between Grate and Planetary Coolers

Grate coolers use a stationary grate with moving hot material, allowing uniform cooling by air flow from below, while planetary coolers involve rotating arms that tumble material for enhanced heat exchange. Grate coolers are ideal for granular and pelletized products requiring steady cooling, whereas planetary coolers excel in handling sticky or cohesive materials due to continuous mixing. Key differences include mechanical design, material agitation method, and suitability for specific feedstock types impacting thermal efficiency and operational flexibility.

Efficiency Comparison: Grate vs Planetary Coolers

Grate coolers exhibit higher thermal efficiency by enabling direct air contact with hot material, facilitating rapid heat exchange and improved cooling rates compared to planetary coolers. Planetary coolers, while offering uniform cooling through tumbling action, tend to have longer residence times and lower heat transfer coefficients, resulting in reduced overall efficiency. Industrial data shows grate coolers can achieve energy savings up to 15% over planetary coolers due to enhanced heat recovery and downstream process integration.

Energy Consumption Analysis

Grate coolers typically consume more energy due to higher airflow requirements and longer cooling times, whereas planetary coolers offer improved energy efficiency by utilizing rotating trays that enhance heat transfer and reduce cooling duration. Your choice between these two cooler types can significantly impact overall operational energy costs, with planetary coolers generally providing lower power consumption and better thermal performance. Understanding the specific process demands and energy profiles of each cooler type is crucial for optimizing energy usage in material cooling systems.

Maintenance Requirements and Longevity

Grate coolers require regular inspection and cleaning of moving grate plates to prevent buildup and ensure efficient cooling, with maintenance often involving lubrication and adjustment of mechanical parts. Planetary coolers, featuring rotating drums with internal lifters, typically experience less wear and require less frequent maintenance, contributing to longer operational life and reduced downtime. The robust design of planetary coolers generally results in enhanced longevity compared to grate coolers, especially in high-capacity industrial applications.

Cost Implications and Investment Considerations

Grate coolers generally require lower initial capital investment compared to planetary coolers but may incur higher maintenance costs due to their moving parts and exposure to abrasive materials. Planetary coolers feature a compact design that often demands higher upfront expenditure but benefits from reduced operational costs through improved heat recovery and less mechanical wear. Evaluating the total cost of ownership, including installation, maintenance, and energy efficiency, is crucial for informed investment decisions in industrial cooling solutions.

Environmental Impact and Emissions

Grate coolers generally produce higher emissions due to increased air leakage and less efficient heat recovery, leading to greater environmental impact compared to planetary coolers. Planetary coolers offer better combustion gas containment and improved energy efficiency, which reduces pollutant release and lowers your facility's carbon footprint. Choosing a planetary cooler can enhance sustainability efforts by minimizing particulate matter and nitrogen oxide emissions during the cooling process.

Selecting the Right Cooler for Your Cement Plant

Selecting the right cooler for your cement plant involves evaluating the Grate cooler's high cooling efficiency, robust heat recovery, and uniform clinker cooling, ideal for energy savings and product quality. Planetary coolers offer simpler design, lower maintenance, and effective handling of variable clinker sizes but may have lower heat recovery efficiency. Understanding your plant's capacity, fuel type, and maintenance capabilities will help ensure your cooler choice optimizes performance and operational costs.

Grate cooler vs Planetary cooler Infographic

libmatt.com

libmatt.com