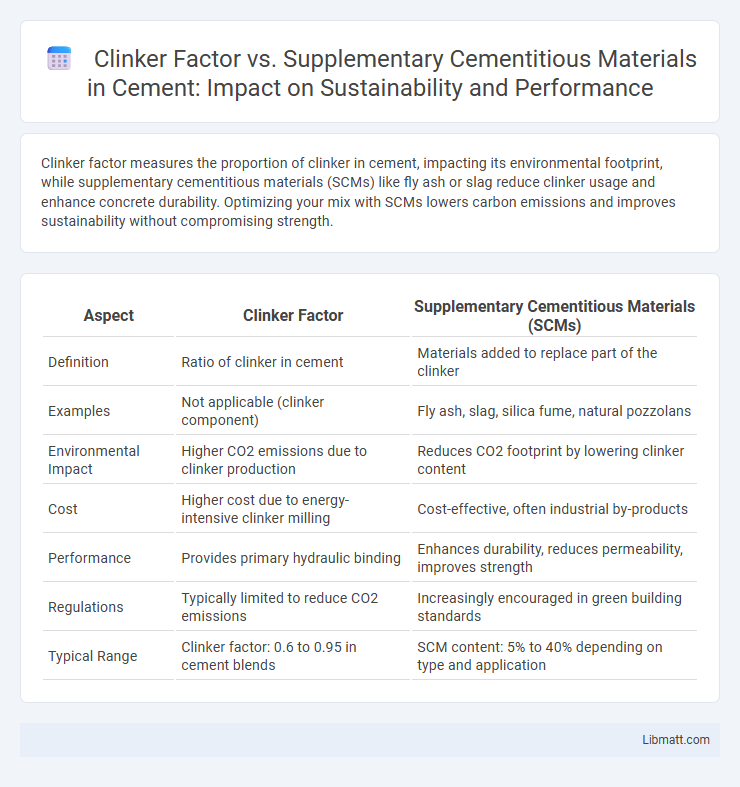

Clinker factor measures the proportion of clinker in cement, impacting its environmental footprint, while supplementary cementitious materials (SCMs) like fly ash or slag reduce clinker usage and enhance concrete durability. Optimizing your mix with SCMs lowers carbon emissions and improves sustainability without compromising strength.

Table of Comparison

| Aspect | Clinker Factor | Supplementary Cementitious Materials (SCMs) |

|---|---|---|

| Definition | Ratio of clinker in cement | Materials added to replace part of the clinker |

| Examples | Not applicable (clinker component) | Fly ash, slag, silica fume, natural pozzolans |

| Environmental Impact | Higher CO2 emissions due to clinker production | Reduces CO2 footprint by lowering clinker content |

| Cost | Higher cost due to energy-intensive clinker milling | Cost-effective, often industrial by-products |

| Performance | Provides primary hydraulic binding | Enhances durability, reduces permeability, improves strength |

| Regulations | Typically limited to reduce CO2 emissions | Increasingly encouraged in green building standards |

| Typical Range | Clinker factor: 0.6 to 0.95 in cement blends | SCM content: 5% to 40% depending on type and application |

Introduction to Clinker Factor and SCMs

Clinker factor represents the proportion of clinker in cement, directly impacting carbon emissions due to clinker production's high energy intensity. Supplementary Cementitious Materials (SCMs) such as fly ash, slag, and silica fume serve as partial clinker replacements, enhancing sustainability by reducing clinker content without compromising cement performance. The integration of SCMs lowers the clinker factor, effectively decreasing the environmental footprint of cement manufacturing.

The Environmental Impact of Clinker in Cement

Clinker production in cement manufacturing contributes significantly to CO2 emissions, accounting for approximately 70-90% of the total carbon footprint due to the calcination of limestone and energy-intensive kiln operations. Supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume reduce clinker factor by partially replacing clinker, leading to lower greenhouse gas emissions and reduced demand for raw materials. Incorporating SCMs enhances sustainability in cement production by decreasing clinker content, which directly mitigates the environmental impact associated with traditional Portland cement.

What Are Supplementary Cementitious Materials (SCMs)?

Supplementary Cementitious Materials (SCMs) are natural or industrial by-products added to concrete to enhance its properties while reducing the clinker factor, which is the proportion of clinker in cement. Common SCMs include fly ash, slag cement, and silica fume, which contribute to improved durability, strength, and sustainability of concrete by partially replacing Portland cement. Your use of SCMs lowers carbon emissions and energy consumption, making concrete production more environmentally friendly.

Reducing Clinker Factor: Key Strategies

Reducing the clinker factor in cement production is primarily achieved by incorporating supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume, which partially replace clinker without compromising concrete performance. SCMs enhance durability, reduce CO2 emissions, and improve workability while maintaining strength, making them essential in sustainable cement manufacturing. Optimizing the blend and proportion of these materials is crucial to achieving significant environmental and economic benefits in reducing the overall clinker factor.

Common Types of SCMs Used in Cement

Supplementary cementitious materials (SCMs) commonly used in cement include fly ash, silica fume, slag cement, and natural pozzolans, each contributing to reduced clinker factor and enhanced concrete properties. Fly ash improves workability and durability, while silica fume increases strength and reduces permeability. Using SCMs effectively lowers your cement's environmental footprint by decreasing the amount of clinker required without compromising performance.

Performance Benefits of Incorporating SCMs

Supplementary cementitious materials (SCMs) improve concrete performance by reducing the clinker factor, leading to enhanced durability, increased resistance to sulfate attack, and lower heat of hydration. SCMs such as fly ash, slag, and silica fume contribute to a denser microstructure and reduced permeability, which extends the lifespan of concrete structures. Your choice to incorporate SCMs can also improve sustainability by lowering carbon emissions associated with cement production.

Economic Implications of Lowering Clinker Content

Lowering clinker content through the use of supplementary cementitious materials (SCMs) like fly ash, slag, or silica fume significantly reduces cement production costs by decreasing energy consumption and raw material requirements. This reduction also lowers CO2 emissions, leading to potential savings in carbon taxes and enhanced compliance with environmental regulations, improving your project's overall economic sustainability. Incorporating SCMs extends the lifespan and durability of concrete, which translates to long-term maintenance savings and improved asset value.

Standards and Regulations for Clinker and SCM use

Standards and regulations governing clinker factor and supplementary cementitious materials (SCMs) are critical for ensuring concrete durability and environmental compliance. Key standards such as ASTM C595 and EN 197-1 specify permissible clinker replacement levels and material properties for SCMs including fly ash, slag, and silica fume. Regulatory frameworks emphasize reducing clinker content to lower CO2 emissions while maintaining performance criteria like compressive strength and setting time in cement production.

Global Trends in Clinker Reduction and SCM Adoption

Global trends indicate a significant shift towards reducing clinker factor in cement production to lower carbon emissions, with widespread adoption of supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume enhancing sustainability. The integration of SCMs improves concrete performance while decreasing reliance on energy-intensive clinker, aligning with international climate goals. You can leverage these innovations to optimize your cement mix designs for environmental compliance and cost efficiency.

Future Perspectives: Innovations in Clinker and SCM Technologies

Future perspectives in clinker factor reduction emphasize breakthroughs in low-carbon clinker formulations and advanced calcination methods to lower CO2 emissions during cement production. Innovations in supplementary cementitious materials (SCMs) focus on novel sources like calcined clays, industrial by-products, and engineered nano-materials that enhance cement performance while minimizing environmental impact. Integrating digital technologies and real-time monitoring systems optimizes SCM blending, enabling more sustainable, high-performance cement with reduced clinker dependency.

Clinker factor vs Supplementary cementitious materials Infographic

libmatt.com

libmatt.com