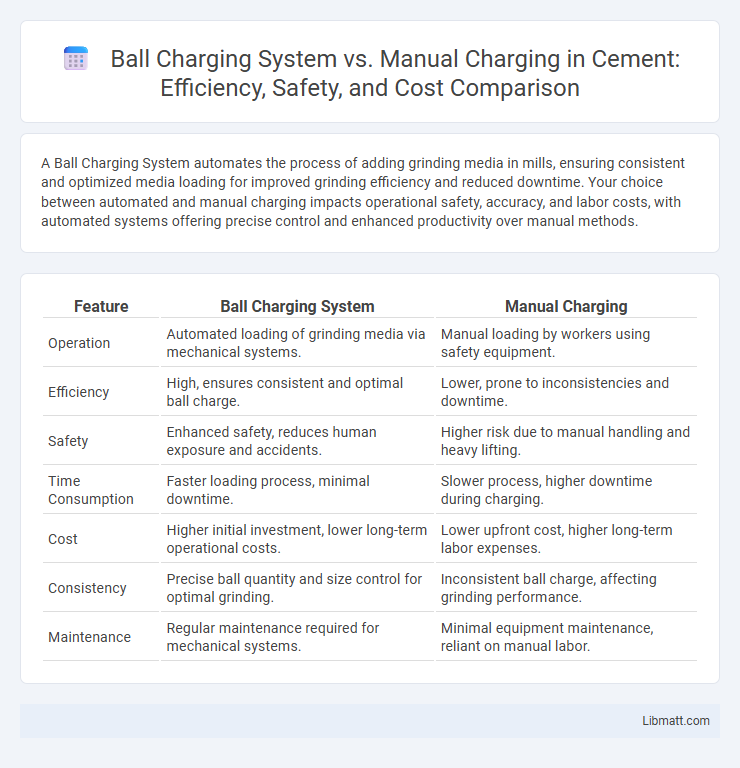

A Ball Charging System automates the process of adding grinding media in mills, ensuring consistent and optimized media loading for improved grinding efficiency and reduced downtime. Your choice between automated and manual charging impacts operational safety, accuracy, and labor costs, with automated systems offering precise control and enhanced productivity over manual methods.

Table of Comparison

| Feature | Ball Charging System | Manual Charging |

|---|---|---|

| Operation | Automated loading of grinding media via mechanical systems. | Manual loading by workers using safety equipment. |

| Efficiency | High, ensures consistent and optimal ball charge. | Lower, prone to inconsistencies and downtime. |

| Safety | Enhanced safety, reduces human exposure and accidents. | Higher risk due to manual handling and heavy lifting. |

| Time Consumption | Faster loading process, minimal downtime. | Slower process, higher downtime during charging. |

| Cost | Higher initial investment, lower long-term operational costs. | Lower upfront cost, higher long-term labor expenses. |

| Consistency | Precise ball quantity and size control for optimal grinding. | Inconsistent ball charge, affecting grinding performance. |

| Maintenance | Regular maintenance required for mechanical systems. | Minimal equipment maintenance, reliant on manual labor. |

Introduction to Ball Charging Systems

Ball charging systems automate the process of loading grinding media into mills, improving consistency and operational efficiency compared to manual charging. These systems use precise measurements and controlled mechanisms to ensure the optimal quantity and distribution of balls, reducing downtime and enhancing safety. Manual charging, while simpler, often leads to variability in loading and increased labor risks, making ball charging systems the preferred solution in modern mining and cement industries.

Overview of Manual Charging Methods

Manual charging methods in ball mills involve the direct placement of grinding media such as steel balls into the mill by hand or with simple mechanical tools, offering straightforward control over the charge volume and size distribution. These methods, though labor-intensive, allow operators to tailor the charge based on operational requirements and mill conditions, influencing grinding efficiency and wear rates. Your choice between manual and automated ball charging can impact maintenance schedules, safety, and overall milling performance.

Key Differences Between Automated and Manual Charging

Ball Charging Systems use automated control to precisely maintain optimal ball load and energy efficiency, whereas Manual Charging relies on operator judgment and periodic adjustments, leading to inconsistent performance. Automation enables real-time monitoring and adjustment, reducing downtime and improving grinding efficiency, while manual methods increase the risk of human error and suboptimal grinding conditions. Your choice impacts productivity, maintenance costs, and overall equipment lifespan due to these fundamental operational differences.

Efficiency Comparison: Ball Charging System vs Manual Charging

Ball Charging Systems offer significantly higher efficiency compared to Manual Charging by enabling precise control over ball size distribution and charging time, resulting in consistent grinding performance. Automated ball feeders reduce human error and increase operational uptime, optimizing energy consumption and improving throughput in milling processes. Studies show that ball charging automation can enhance grinding efficiency by up to 15%, translating into reduced operational costs and improved productivity.

Safety Considerations in Ball Handling

Automated Ball Charging Systems significantly enhance safety by minimizing direct human contact with heavy grinding media, reducing the risk of injuries caused by manual lifting and dropping. These systems are equipped with protective features such as controlled feed mechanisms and emergency stop functions, ensuring safer ball handling environments. You benefit from reduced ergonomic hazards and improved compliance with safety standards compared to traditional manual charging methods.

Cost Analysis: Automated vs Manual Ball Charging

Automated ball charging systems significantly reduce labor costs and minimize downtime compared to manual charging, leading to greater operational efficiency in grinding mills. Although the initial investment in an automated system is higher, the long-term savings on labor, improved safety, and consistent charging accuracy lower overall maintenance and operational expenses. Your facility can achieve better cost control and enhanced productivity by adopting automated ball charging over manual methods.

Impact on Operational Downtime

Automated Ball Charging Systems significantly reduce operational downtime by ensuring consistent, precise ball replenishment without halting grinding processes, unlike manual charging which requires equipment shutdown and exposes plants to human error. The continuous operation enabled by automated systems maintains optimal mill performance and prolongs equipment life, enhancing overall productivity. Manual charging, in contrast, extends downtime due to frequent maintenance stops and slower charging cycles, directly impacting operational efficiency.

Maintenance and Durability Factors

Ball charging systems reduce wear and maintenance costs by providing consistent and controlled media flow, minimizing liner and grinding media damage. Manual charging often results in irregular media distribution, increasing the risk of equipment wear and downtime due to inconsistent grinding performance. Automated ball charging enhances durability by ensuring optimal media size and quantity, extending mill liner life and reducing maintenance frequency.

Environmental and Workplace Implications

Ball Charging Systems reduce dust emissions and noise pollution compared to Manual Charging, enhancing air quality and worker health in industrial settings. Automated systems minimize direct human exposure to hazardous materials, lowering the risk of accidents and repetitive strain injuries. Environmental benefits include less material spillage and waste, contributing to more sustainable operational practices.

Choosing the Right Charging Method for Your Operation

Selecting the appropriate ball charging system significantly enhances grinding efficiency and operational safety in mining and cement plants. Automated ball charging systems provide precise, consistent load control and reduce labor risks compared to manual charging, which is prone to errors and safety hazards. Integrating sensor-based monitoring allows real-time adjustments, optimizing mill performance and reducing downtime costs.

Ball Charging System vs Manual Charging Infographic

libmatt.com

libmatt.com