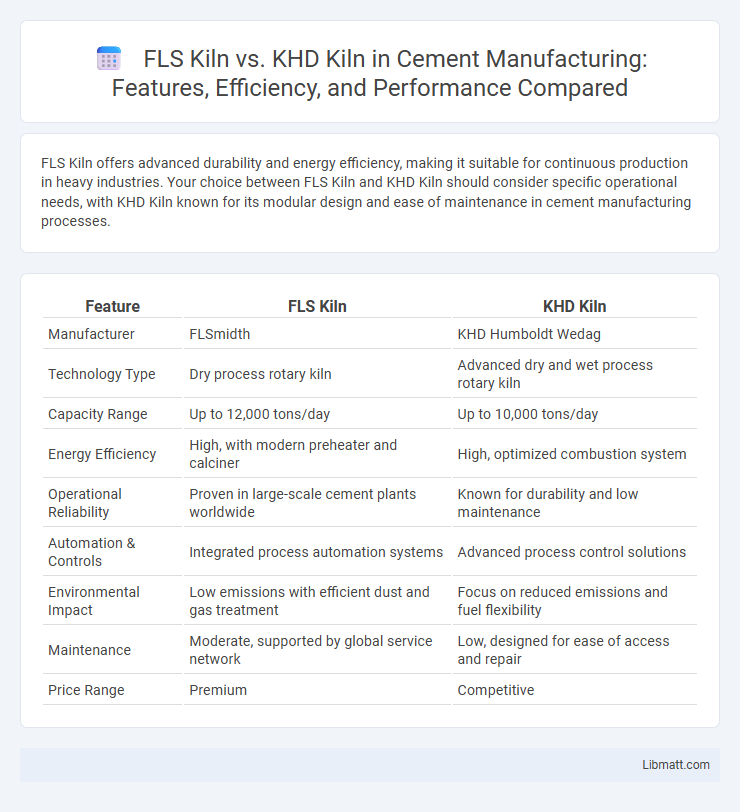

FLS Kiln offers advanced durability and energy efficiency, making it suitable for continuous production in heavy industries. Your choice between FLS Kiln and KHD Kiln should consider specific operational needs, with KHD Kiln known for its modular design and ease of maintenance in cement manufacturing processes.

Table of Comparison

| Feature | FLS Kiln | KHD Kiln |

|---|---|---|

| Manufacturer | FLSmidth | KHD Humboldt Wedag |

| Technology Type | Dry process rotary kiln | Advanced dry and wet process rotary kiln |

| Capacity Range | Up to 12,000 tons/day | Up to 10,000 tons/day |

| Energy Efficiency | High, with modern preheater and calciner | High, optimized combustion system |

| Operational Reliability | Proven in large-scale cement plants worldwide | Known for durability and low maintenance |

| Automation & Controls | Integrated process automation systems | Advanced process control solutions |

| Environmental Impact | Low emissions with efficient dust and gas treatment | Focus on reduced emissions and fuel flexibility |

| Maintenance | Moderate, supported by global service network | Low, designed for ease of access and repair |

| Price Range | Premium | Competitive |

Introduction to Rotary Kilns: FLS vs KHD

Rotary kilns from FLS and KHD are engineered to optimize thermal processing in cement and mineral industries, featuring robust designs for continuous operation. FLS kilns emphasize energy efficiency and modular construction, enabling easy maintenance and scalability, while KHD kilns are renowned for their precise temperature control and advanced refractory lining technology. Both manufacturers provide tailored solutions that enhance fuel consumption and product quality, addressing diverse industrial requirements.

Core Design Differences: FLS Kiln vs KHD Kiln

FLS Kiln features a modular design with a focus on energy efficiency and ease of maintenance, allowing for quick replacement of key components and optimized heat recovery systems. KHD Kiln emphasizes robust construction with integrated process control technologies and high heat transfer efficiency, designed to enhance reliability and operational performance in heavy-duty applications. Understanding these core design differences helps you select the kiln best suited for your specific industrial requirements and process conditions.

Energy Efficiency Comparison

FLS Kilns generally offer advanced energy-saving technologies, including optimized heat recovery systems that reduce fuel consumption by up to 15%, while KHD Kilns emphasize thermal insulation improvements for consistent energy retention. Both brands incorporate state-of-the-art control systems to monitor and adjust fuel usage in real-time, leading to improved operational efficiency. When evaluating energy efficiency for your specific needs, consider the process heat recovery capabilities and fuel optimization features each kiln provides to maximize cost savings.

Process Control and Automation Features

FLS kilns offer advanced process control systems with real-time monitoring, adaptive algorithms, and user-friendly interfaces that optimize thermal efficiency and product quality. KHD kilns integrate high-precision automation technologies, including PLC-based controls and predictive maintenance tools, enhancing operational stability and reducing downtime. Both systems utilize data-driven analytics to ensure consistent output and energy savings, but KHD emphasizes modular automation for scalable customization.

Maintenance and Durability Evaluation

FLS Kilns are renowned for their robust construction and ease of maintenance, featuring modular designs that allow quick part replacements and reduced downtime. KHD Kilns offer advanced durability with high-quality materials designed to withstand extreme thermal and mechanical stress, minimizing long-term wear and maintenance frequency. Your choice between FLS and KHD should consider maintenance accessibility and the kiln's expected operational lifespan to optimize performance and cost-efficiency.

Output Quality and Material Consistency

FLS Kilns are renowned for delivering superior output quality with precise temperature control, ensuring consistent material properties throughout the production cycle. KHD Kilns offer advanced innovation in combustion technology, providing stable heat distribution that maintains uniformity in raw material transformation. For your operations, choosing between FLS and KHD Kilns means prioritizing either meticulous material consistency or enhanced thermal performance to meet output quality standards.

Environmental Impact and Compliance

FLS Kilns utilize advanced combustion systems that reduce NOx and CO2 emissions, ensuring compliance with stringent environmental regulations such as the EU Industrial Emissions Directive. KHD Kilns are equipped with efficient heat recovery and exhaust gas treatment technologies, minimizing particulate matter and sulfur oxide releases to meet global emission standards. Both systems integrate real-time monitoring to optimize energy use and maintain regulatory compliance, supporting sustainable cement production.

Operational Costs and Lifecycle Value

FLS Kilns typically offer lower operational costs due to higher fuel efficiency and simplified maintenance processes, resulting in reduced downtime and resource consumption. KHD Kilns, while sometimes having higher upfront investment, provide significant lifecycle value through robust construction and advanced control systems that enhance durability and process stability over time. Your choice depends on balancing immediate cost savings with long-term performance and total cost of ownership considerations.

User Experiences and Industry Case Studies

User experiences with FLS Kiln often highlight its robust reliability and ease of maintenance, translating to reduced downtime in cement production facilities. Industry case studies reveal that KHD Kiln systems excel in energy efficiency and process automation, leading to significant fuel savings and enhanced product quality. Your choice between FLS and KHD Kiln should consider long-term operational costs and the specific needs demonstrated in similar industrial applications.

Choosing the Right Kiln: FLS or KHD?

Selecting the right kiln between FLS and KHD hinges on factors such as production capacity, energy efficiency, and maintenance requirements. FLS kilns are renowned for their robust design and high throughput, making them ideal for large-scale cement manufacturing. Conversely, KHD kilns offer advanced process control and lower energy consumption, appealing to operations prioritizing sustainability and precise operational management.

FLS Kiln vs KHD Kiln Infographic

libmatt.com

libmatt.com