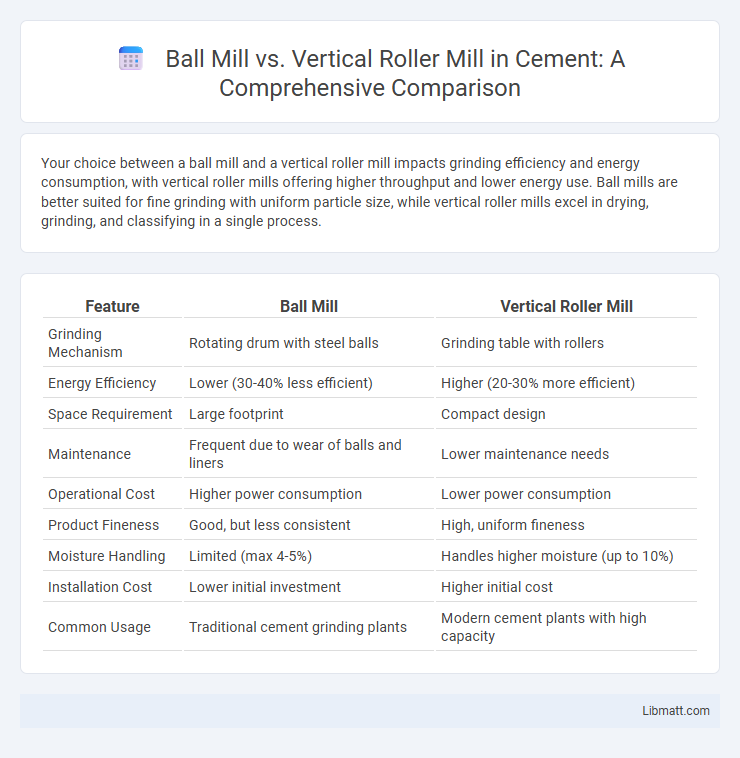

Your choice between a ball mill and a vertical roller mill impacts grinding efficiency and energy consumption, with vertical roller mills offering higher throughput and lower energy use. Ball mills are better suited for fine grinding with uniform particle size, while vertical roller mills excel in drying, grinding, and classifying in a single process.

Table of Comparison

| Feature | Ball Mill | Vertical Roller Mill |

|---|---|---|

| Grinding Mechanism | Rotating drum with steel balls | Grinding table with rollers |

| Energy Efficiency | Lower (30-40% less efficient) | Higher (20-30% more efficient) |

| Space Requirement | Large footprint | Compact design |

| Maintenance | Frequent due to wear of balls and liners | Lower maintenance needs |

| Operational Cost | Higher power consumption | Lower power consumption |

| Product Fineness | Good, but less consistent | High, uniform fineness |

| Moisture Handling | Limited (max 4-5%) | Handles higher moisture (up to 10%) |

| Installation Cost | Lower initial investment | Higher initial cost |

| Common Usage | Traditional cement grinding plants | Modern cement plants with high capacity |

Introduction to Ball Mills and Vertical Roller Mills

Ball mills and vertical roller mills are essential grinding equipment in the cement and mining industries, used to reduce raw materials into fine powders for further processing. Ball mills consist of a rotating cylindrical shell filled with steel balls that grind materials through impact and attrition, while vertical roller mills employ rollers that crush materials against a rotating grinding table using high pressure. Vertical roller mills offer advantages in energy efficiency and space-saving designs compared to traditional ball mills, making them increasingly popular in modern industrial applications.

Key Differences in Design and Structure

Ball mills utilize rotating cylindrical shells filled with grinding media to crush materials through impact and attrition, while vertical roller mills employ rotating rollers on a grinding table, applying pressure and shear for grinding. The ball mill design is characterized by horizontal alignment and reliance on cascading motion inside the drum, whereas vertical roller mills are vertically oriented with integrated separation systems improving grinding efficiency. You'll find vertical roller mills generally more compact with lower energy consumption, contrasting with the more traditional, bulkier structure of ball mills.

Grinding Efficiency and Particle Size Distribution

Vertical roller mills offer higher grinding efficiency by utilizing compressive forces that reduce energy consumption compared to ball mills, which rely on impact and attrition. The particle size distribution in vertical roller mills is narrower and more uniform, resulting in improved product quality and consistency. Your choice between these mills affects operational costs and product fineness, with vertical roller mills generally preferred for producing finer particles at lower energy use.

Energy Consumption Comparison

Vertical roller mills consume significantly less energy than ball mills due to their efficient grinding mechanism and lower power requirements. Ball mills typically require more electricity because they use rotating cylinders filled with grinding media, resulting in higher friction and heat loss. Optimizing your grinding process with a vertical roller mill can reduce energy costs and improve overall plant efficiency.

Installation and Space Requirements

Ball mills require a larger installation footprint and more structural support due to their heavy rotating drums and foundation needs, leading to increased construction costs and longer setup times. Vertical roller mills have a more compact design with a smaller footprint, allowing for easier installation and integration within existing plant layouts, which reduces space requirements and associated expenses. The vertical roller mill's modular construction also facilitates faster assembly and maintenance access compared to the extensive foundation work necessary for ball mills.

Maintenance and Operational Costs

Vertical roller mills generally offer lower maintenance and operational costs compared to ball mills due to their fewer moving parts and more efficient grinding mechanics. Ball mills require regular replacement of liners and grinding media, leading to higher downtime and maintenance expenses. The energy consumption of vertical roller mills is also significantly lower, contributing to reduced operational costs over the equipment's lifespan.

Application Areas and Material Suitability

Ball mills are widely used in cement, mining, and chemical industries for grinding hard, abrasive materials such as clinker, ores, and minerals. Vertical roller mills excel in processing raw materials with varying moisture content and are highly effective in grinding materials like limestone, slag, and coal. The vertical roller mill's energy efficiency and ability to handle larger particle sizes make it suitable for large-scale industrial applications, while ball mills are preferred for fine grinding tasks and smaller batch sizes.

Environmental Impact and Dust Control

Ball mills typically generate higher dust emissions and consume more energy compared to vertical roller mills, resulting in a larger environmental footprint. Vertical roller mills incorporate advanced dust control systems and operate at lower energy levels, reducing particulate emissions and minimizing environmental impact. Choosing your grinding equipment with vertical roller mills can contribute to enhanced dust control and improved sustainability in industrial processes.

Performance in Cement and Mining Industries

Ball mills feature a rotating cylinder filled with grinding media that crushes raw materials through impact and attrition, offering consistent particle size distribution and high grinding capacity crucial for cement and mining operations. Vertical roller mills utilize large rollers that apply pressure on the material bed, resulting in energy-efficient grinding with lower power consumption and reduced operational costs. In cement and mining industries, vertical roller mills deliver improved drying capacity and finer product quality, whereas ball mills excel in handling harder materials and achieving uniform particle size for specific processing requirements.

Final Recommendations and Selection Criteria

When choosing between a ball mill and a vertical roller mill, consider factors such as energy efficiency, maintenance costs, and product fineness requirements. Vertical roller mills offer higher energy savings and better drying capabilities, ideal for cement grinding and large-scale operations, while ball mills provide greater flexibility and simpler maintenance for diverse materials. Your final selection should balance operational costs, desired throughput, and material characteristics to optimize performance and sustainability.

Ball mill vs Vertical roller mill Infographic

libmatt.com

libmatt.com