Rapid hardening cement achieves high early strength within 3 days, making it ideal for urgent construction projects, while Ordinary Portland Cement (OPC) gains strength gradually over 28 days, providing long-term durability. You should choose rapid hardening cement when quick setting and early strength are critical, whereas OPC suits general construction requiring standard curing times.

Table of Comparison

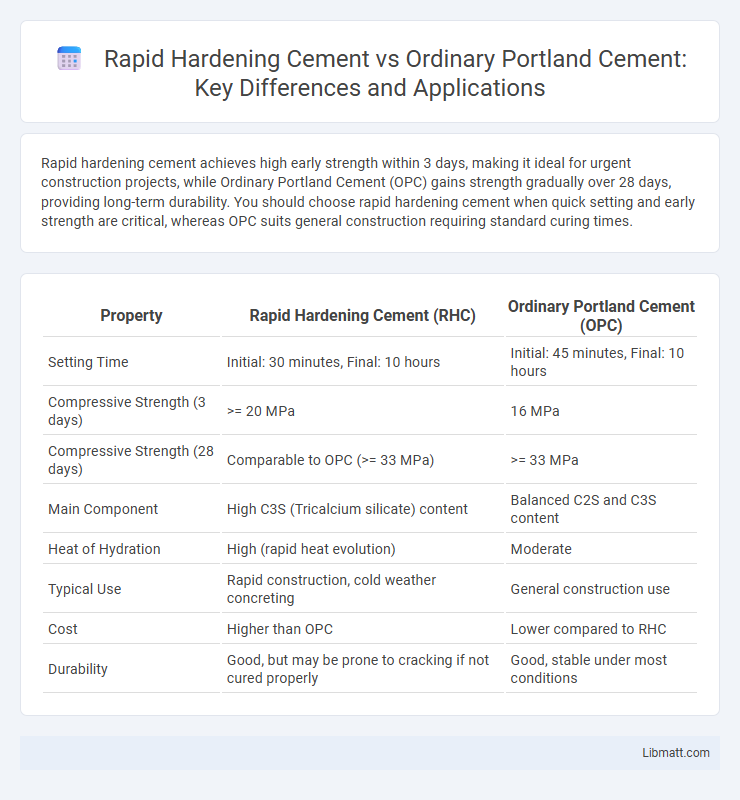

| Property | Rapid Hardening Cement (RHC) | Ordinary Portland Cement (OPC) |

|---|---|---|

| Setting Time | Initial: 30 minutes, Final: 10 hours | Initial: 45 minutes, Final: 10 hours |

| Compressive Strength (3 days) | >= 20 MPa | 16 MPa |

| Compressive Strength (28 days) | Comparable to OPC (>= 33 MPa) | >= 33 MPa |

| Main Component | High C3S (Tricalcium silicate) content | Balanced C2S and C3S content |

| Heat of Hydration | High (rapid heat evolution) | Moderate |

| Typical Use | Rapid construction, cold weather concreting | General construction use |

| Cost | Higher than OPC | Lower compared to RHC |

| Durability | Good, but may be prone to cracking if not cured properly | Good, stable under most conditions |

Introduction to Cement Types

Rapid hardening cement achieves high early strength within 3 days due to increased C3S clinker phases and finer grinding, making it ideal for time-sensitive construction. Ordinary Portland cement (OPC) has a balanced hydration rate with standard strength development over 28 days, suitable for general construction purposes. Key differences lie in their chemical composition, setting time, and early strength parameters, influencing project scheduling and structural requirements.

What is Rapid Hardening Cement?

Rapid Hardening Cement is a type of cement designed to achieve high early strength within the first few days of curing, making it ideal for projects requiring quick setting and early load-bearing capacity. Its finer grinding and higher lime content accelerate the hydration process compared to Ordinary Portland Cement, which develops strength more gradually over weeks. You can use Rapid Hardening Cement in repairs, precast work, and cold weather concreting where early strength gain is crucial.

What is Ordinary Portland Cement?

Ordinary Portland Cement (OPC) is a common type of cement widely used in construction, known for its versatility and strength development over time. It is composed primarily of clinker and gypsum, which contribute to its durability and setting characteristics. Your choice between OPC and rapid hardening cement depends on project requirements such as setting time and strength gain.

Key Composition Differences

Rapid hardening cement contains a higher percentage of tricalcium silicate (C3S) compared to Ordinary Portland cement, which accelerates its hydration process and strength gain. The increased lime (CaO) content and finer grind size in rapid hardening cement contribute to faster setting and early strength development within 3 to 7 days, unlike the slower 28-day curing period typical for Ordinary Portland cement. Your choice between these cements depends on project timelines, as rapid hardening cement is ideal for urgent repairs and early load application.

Strength Development Comparison

Rapid hardening cement achieves high early strength, reaching up to 70 MPa within 3 days, compared to Ordinary Portland Cement (OPC), which typically attains around 20 MPa in the same period. This accelerated strength gain is due to the higher C3S (tricalcium silicate) content and finer grinding of rapid hardening cement. While OPC continues to gain strength steadily over 28 days, rapid hardening cement provides a faster load-bearing capacity, making it ideal for time-sensitive construction projects.

Setting Time and Workability

Rapid hardening cement achieves initial setting within 20 to 30 minutes and final setting in 45 minutes to 1 hour, significantly faster than Ordinary Portland cement, which typically sets initially in 30 to 45 minutes and finally in 10 hours. The accelerated hydration rate of rapid hardening cement enhances early strength but can reduce workability time, requiring quicker placement and finishing. Ordinary Portland cement provides longer workability windows, allowing more flexibility during concrete mixing and application, making it suitable for complex formworks.

Applications and Use Cases

Rapid hardening cement is ideal for projects requiring quick strength gain, such as road repairs, precast concrete production, and emergency construction works, where early load application is critical. Ordinary Portland cement is widely used in general construction including residential buildings, bridges, and pavements where standard curing time is acceptable. The choice depends on project timelines, with rapid hardening cement enabling faster formwork removal and early use, while OPC is preferred for cost-effective, long-term strength development.

Durability and Longevity

Rapid hardening cement offers enhanced durability and longevity compared to Ordinary Portland Cement (OPC) due to its faster strength gain, which allows structures to achieve early load-bearing capacity and resist environmental stresses more effectively. The accelerated hydration process in rapid hardening cement reduces the risk of early-age cracking and enhances resistance to sulfate attacks and freeze-thaw cycles. Your construction projects benefit from extended service life and reduced maintenance costs when choosing rapid hardening cement over OPC for critical applications.

Cost and Availability

Rapid hardening cement generally costs 10-15% more than Ordinary Portland Cement (OPC) due to the higher quantities of clinker and finer grinding required. Availability of Rapid hardening cement is more limited compared to OPC, as it is typically produced in specialized plants and used for specific applications like urgent repairs and early strength requirements. OPC remains widely available globally and is preferred for general construction projects because of its cost-effectiveness and widespread distribution.

Choosing the Right Cement for Your Project

Rapid hardening cement achieves high early strength within 3 days, making it ideal for projects requiring quick formwork removal or fast construction schedules. Ordinary Portland cement gains strength more gradually over 28 days, offering durability and cost-effectiveness for standard construction tasks. Selecting the appropriate cement depends on project timelines, structural requirements, and environmental conditions to ensure optimal performance and longevity.

Rapid hardening cement vs Ordinary Portland cement Infographic

libmatt.com

libmatt.com