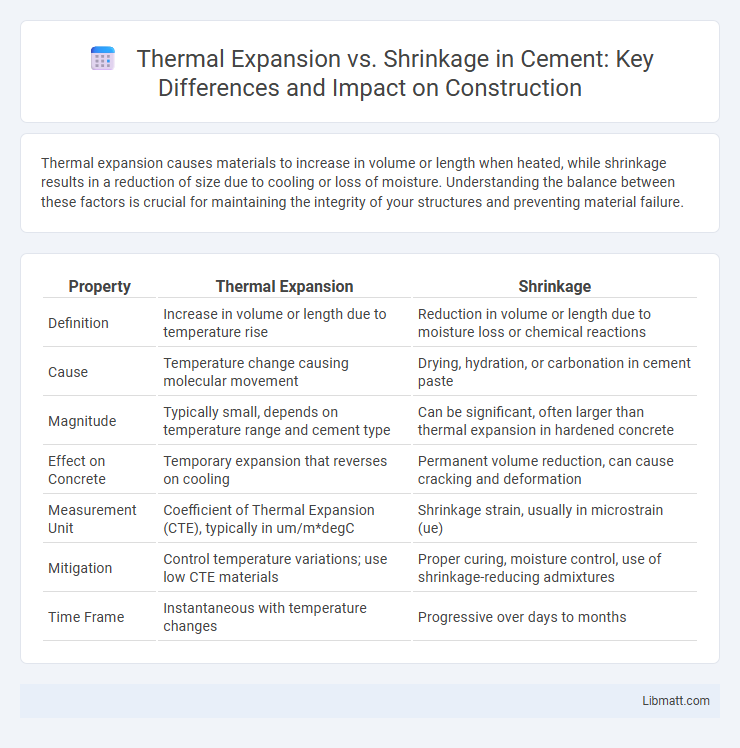

Thermal expansion causes materials to increase in volume or length when heated, while shrinkage results in a reduction of size due to cooling or loss of moisture. Understanding the balance between these factors is crucial for maintaining the integrity of your structures and preventing material failure.

Table of Comparison

| Property | Thermal Expansion | Shrinkage |

|---|---|---|

| Definition | Increase in volume or length due to temperature rise | Reduction in volume or length due to moisture loss or chemical reactions |

| Cause | Temperature change causing molecular movement | Drying, hydration, or carbonation in cement paste |

| Magnitude | Typically small, depends on temperature range and cement type | Can be significant, often larger than thermal expansion in hardened concrete |

| Effect on Concrete | Temporary expansion that reverses on cooling | Permanent volume reduction, can cause cracking and deformation |

| Measurement Unit | Coefficient of Thermal Expansion (CTE), typically in um/m*degC | Shrinkage strain, usually in microstrain (ue) |

| Mitigation | Control temperature variations; use low CTE materials | Proper curing, moisture control, use of shrinkage-reducing admixtures |

| Time Frame | Instantaneous with temperature changes | Progressive over days to months |

Introduction to Thermal Expansion and Shrinkage

Thermal expansion and shrinkage describe how materials change size in response to temperature variations, with expansion occurring when materials heat up and shrinkage happening as they cool down. These phenomena are critical in engineering and construction, where precise measurements can prevent structural damage or failure. Understanding thermal expansion and shrinkage helps you design systems that accommodate these predictable changes, ensuring durability and safety.

Understanding Thermal Expansion: Definition and Principles

Thermal expansion refers to the increase in a material's volume or length when its temperature rises, caused by the increased kinetic energy of atoms leading to greater atomic spacing. The degree of expansion depends on the material's coefficient of thermal expansion, temperature change, and initial dimensions. Understanding these principles is crucial for engineering applications where dimensional stability under temperature fluctuations is essential.

What is Shrinkage? Causes and Mechanisms

Shrinkage refers to the reduction in volume or dimensions of materials as they cool or dry, primarily caused by the loss of moisture or the contraction of molecular structures. Common mechanisms include moisture evaporation in concrete, thermal contraction in metals during cooling, and polymer chain relaxation in plastics. Understanding shrinkage is crucial for predicting material behavior and preventing structural defects in construction and manufacturing processes.

Key Differences Between Thermal Expansion and Shrinkage

Thermal expansion is the increase in a material's volume or length when heated, whereas shrinkage refers to the decrease in size, often occurring during cooling or solidification. Key differences include expansion resulting from heat energy causing atomic vibrations to increase spacing, while shrinkage typically happens due to loss of heat or drying, leading to contraction. Understanding these properties is essential for managing material behavior in applications like construction, manufacturing, and engineering to ensure Your designs accommodate dimensional changes.

Material Properties Influencing Expansion and Shrinkage

Thermal expansion and shrinkage depend heavily on material properties such as the coefficient of thermal expansion, which varies significantly between metals, ceramics, and polymers. Materials with higher coefficients, like aluminum and rubber, exhibit greater dimensional changes with temperature fluctuations, while materials with low coefficients, such as glass and concrete, demonstrate minimal expansion or shrinkage. The microstructure, moisture content, and crystalline or amorphous nature of the material also influence its response to temperature changes by affecting atomic bond flexibility and molecular mobility.

Effects of Temperature Changes on Materials

Temperature changes cause thermal expansion in materials as atoms vibrate more at higher temperatures, increasing the material's volume. Conversely, cooling leads to shrinkage due to decreased atomic vibration and contraction of the material's structure. These dimensional changes impact mechanical properties, structural integrity, and performance in applications like construction, manufacturing, and electronics.

Real-World Examples of Expansion and Shrinkage

Railway tracks expand in hot weather, requiring gaps known as expansion joints to prevent buckling, while concrete structures shrink as they cure, leading to potential cracking if not properly controlled. Bridges often incorporate expansion joints to absorb thermal expansion during summer and contraction in winter, ensuring structural integrity. Wood furniture and flooring can shrink in low humidity environments, causing gaps, and expand in high humidity, leading to warping or buckling.

Engineering Solutions to Manage Expansion and Shrinkage

Engineering solutions to manage thermal expansion and shrinkage include the use of expansion joints, flexible materials, and control of temperature fluctuations within structures. Accurate material selection and precise design calculations ensure that thermal stresses are minimized, preventing structural damage and maintaining durability. Your project benefits from integrated systems that accommodate dimensional changes, enhancing safety and longevity.

Testing Methods for Measuring Expansion and Shrinkage

Thermal expansion and shrinkage are commonly measured using dilatometers, which provide precise dimensional changes under controlled temperature variations. Laser interferometry offers non-contact, high-resolution measurements essential for detecting minute expansions and contractions in materials. Thermomechanical analysis (TMA) complements these methods by applying mechanical loads while monitoring dimensional changes, enabling comprehensive evaluation of thermal behavior.

Conclusion: Importance in Design and Material Selection

Thermal expansion and shrinkage significantly influence material behavior under temperature variations, making accurate predictions essential for structural integrity. Designers must consider expansion coefficients and shrinkage rates to prevent deformation, cracks, or failure in components exposed to thermal cycles. Your material selection should align with operational temperature ranges and mechanical demands to ensure long-term durability and performance.

Thermal expansion vs Shrinkage Infographic

libmatt.com

libmatt.com