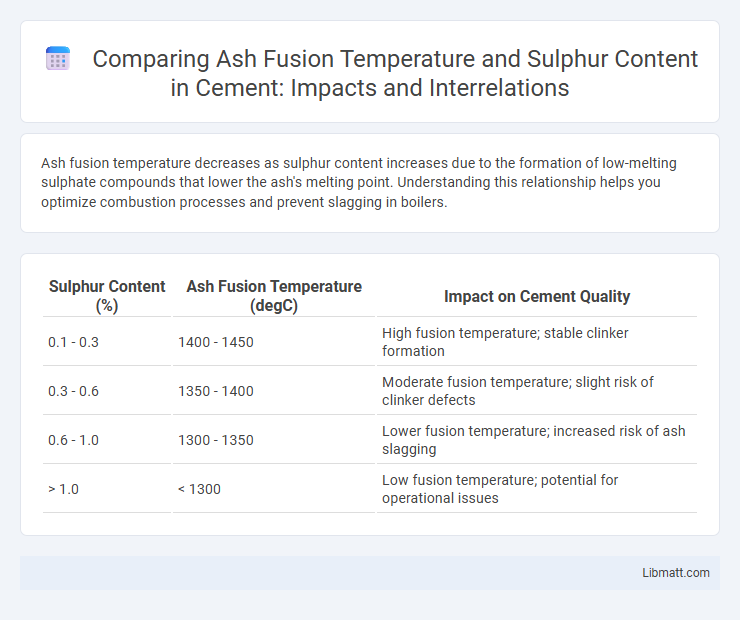

Ash fusion temperature decreases as sulphur content increases due to the formation of low-melting sulphate compounds that lower the ash's melting point. Understanding this relationship helps you optimize combustion processes and prevent slagging in boilers.

Table of Comparison

| Sulphur Content (%) | Ash Fusion Temperature (degC) | Impact on Cement Quality |

|---|---|---|

| 0.1 - 0.3 | 1400 - 1450 | High fusion temperature; stable clinker formation |

| 0.3 - 0.6 | 1350 - 1400 | Moderate fusion temperature; slight risk of clinker defects |

| 0.6 - 1.0 | 1300 - 1350 | Lower fusion temperature; increased risk of ash slagging |

| > 1.0 | < 1300 | Low fusion temperature; potential for operational issues |

Introduction to Ash Fusion Temperature and Sulphur Content

Ash fusion temperature measures the melting point of ash formed from mineral residues in fuels, critical for preventing slagging in combustion systems. Sulphur content in fuel influences ash chemistry, affecting fusion temperatures and causing operational issues like clinker formation. Understanding the relationship between ash fusion temperature and sulphur content helps optimize fuel selection and combustion efficiency for your system.

Significance of Ash Fusion Temperature in Fuel Quality

Ash fusion temperature directly impacts fuel quality by indicating the temperature at which ash melts and can cause slagging or fouling in combustion systems. Higher sulphur content in fuel often lowers the ash fusion temperature, increasing the risk of operational issues and equipment damage. Understanding this relationship helps you select fuels that minimize maintenance costs and improve overall combustion efficiency.

Understanding Sulphur Content in Solid Fuels

Sulphur content in solid fuels significantly influences the ash fusion temperature, which determines the behavior of ash during combustion. Higher sulphur levels typically lower the ash fusion temperature, causing earlier melting and slagging issues in furnaces and boilers. Understanding this relationship helps you optimize fuel selection and combustion conditions to prevent operational problems and extend equipment lifespan.

Chemical Composition Influencing Ash Fusion Temperature

The chemical composition of ash, particularly the content of silica, alumina, iron oxides, and calcium oxide, directly influences the ash fusion temperature, with higher concentrations of fluxing agents like calcium and iron oxides typically lowering the melting point. Sulfur content affects the formation of sulfates in ash, which can modify the ash fusion characteristics by altering the crystalline phases and thus either increasing or decreasing the ash fusion temperature depending on the interaction with other oxides. Understanding the precise relationship between sulfur content and ash fusion behavior is critical for optimizing combustion efficiency and preventing slagging problems in industrial furnaces and boilers.

The Impact of Sulphur Content on Ash Fusibility

Sulphur content significantly influences ash fusion temperature by lowering the melting point of ash in coal combustion. Higher sulphur levels promote the formation of low-melting-point compounds, causing ash to become fusible at lower temperatures and increasing the risk of slagging and fouling in boilers. Understanding this relationship helps you optimize fuel selection and boiler operation to minimize maintenance and improve efficiency.

Mechanisms Linking Sulphur with Ash Melting Behavior

Sulphur influences ash fusion temperature by forming sulfates and sulfides that alter the chemical composition of ash, promoting lower melting points. The interaction of sulphur with alkali metals, such as potassium and sodium, leads to the formation of low-melting eutectics, which enhances ash liquefaction during combustion. Understanding these mechanisms helps you predict and control ash behavior for optimized fuel performance and reduced slagging risks.

Laboratory Methods for Measuring Ash Fusion Temperature

Laboratory methods for measuring ash fusion temperature typically involve heating a prepared ash sample in a high-temperature furnace while observing physical changes such as shrinkage, rounding, and melting at defined temperature points: initial deformation, softening, hemispherical, and flow temperatures. Optical and video-based heating stages provide precise measurement of these characteristic temperatures, critical for understanding ash behavior in combustion and gasification processes. Standardized techniques like ASTM D1857 use controlled conditions and sample shapes to ensure reproducible and accurate results reflecting the influence of sulphur content on ash fusion behavior.

Correlation Studies: Sulphur Content vs. Ash Fusion Temperature

Correlation studies between sulphur content and ash fusion temperature reveal that higher sulphur concentrations often lead to the formation of low-melting-point sulfates, which decrease the ash fusion temperature. This relationship is critical for coal combustion processes, as it affects slagging and fouling tendencies in boilers. Understanding the impact of sulphur on ash fusion characteristics helps optimize fuel selection and combustion conditions for improved thermal efficiency and reduced operational issues.

Implications for Industrial Combustion and Boiler Operations

Higher sulphur content in fuel increases ash fusion temperature, impacting slagging and fouling tendencies in industrial combustion and boiler operations. Elevated ash fusion temperatures necessitate more robust refractory materials and adjusted combustion temperatures to prevent deposit formation and corrosion. Understanding this relationship optimizes boiler efficiency, reduces maintenance costs, and extends operational lifespan in power plants and heavy industries.

Strategies to Manage High Sulphur and Low Ash Fusion Issues

Managing high sulphur content and low ash fusion temperatures in coal requires strategic blending of low-sulphur, high ash fusion coals to achieve desired combustion properties. Employing additives such as fluxing agents can elevate ash fusion temperatures, reducing slagging and fouling risks during thermal processes. Monitoring and adjusting combustion parameters optimizes operational efficiency and prolongs boiler lifespan by preventing corrosion linked to sulphur oxide formation.

Ash Fusion Temperature vs Sulphur Content Infographic

libmatt.com

libmatt.com