Soft burning produces slower, cooler flames ideal for delicate ceramics or slow cooking, preserving texture and preventing damage. Hard burning generates high heat with rapid combustion, suitable for metalworking or situations requiring intense temperature and quick results.

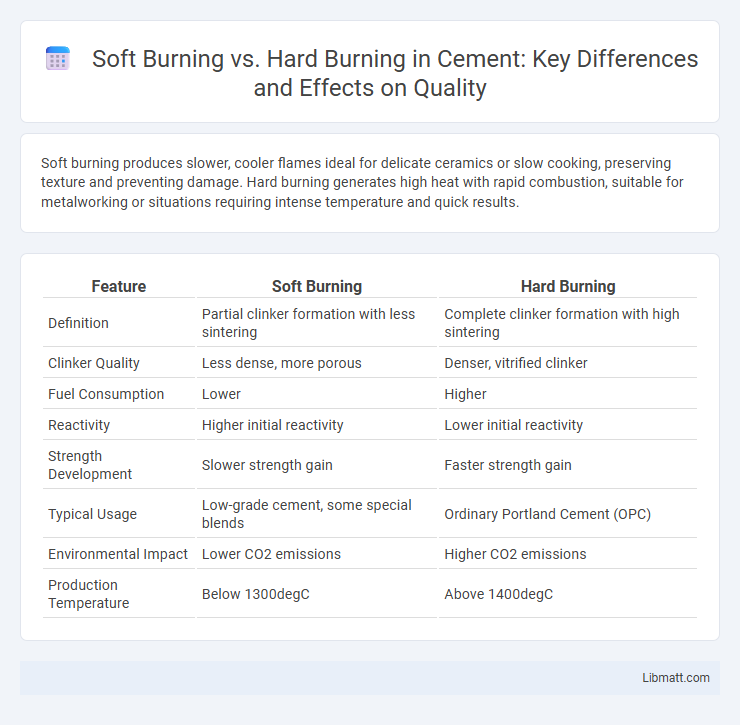

Table of Comparison

| Feature | Soft Burning | Hard Burning |

|---|---|---|

| Definition | Partial clinker formation with less sintering | Complete clinker formation with high sintering |

| Clinker Quality | Less dense, more porous | Denser, vitrified clinker |

| Fuel Consumption | Lower | Higher |

| Reactivity | Higher initial reactivity | Lower initial reactivity |

| Strength Development | Slower strength gain | Faster strength gain |

| Typical Usage | Low-grade cement, some special blends | Ordinary Portland Cement (OPC) |

| Environmental Impact | Lower CO2 emissions | Higher CO2 emissions |

| Production Temperature | Below 1300degC | Above 1400degC |

Introduction to Soft Burning and Hard Burning

Soft burning refers to a controlled firing process in ceramics and brick production where the temperature is kept relatively low to preserve the structural integrity and reduce shrinkage. Hard burning involves higher temperatures that vitrify the material, resulting in increased strength, density, and durability, often used for industrial-grade bricks and tiles. Understanding the differences in temperature ranges and outcomes helps optimize material properties for specific construction and artistic applications.

Defining Soft Burning: Key Characteristics

Soft burning refers to the slow, low-temperature combustion process that minimizes the release of pollutants and preserves material integrity. Key characteristics include lower heat output, reduced flame intensity, and production of less smoke compared to hard burning. Your choice of soft burning methods can enhance energy efficiency while maintaining environmental standards.

Understanding Hard Burning: Essential Features

Hard burning involves using higher temperatures and slower cooling rates during heat treatment, resulting in increased hardness, strength, and wear resistance of materials. Essential features of hard burning include the formation of a martensitic microstructure and reduced ductility, making it ideal for applications requiring durable, impact-resistant components. Understanding these characteristics helps you select the appropriate process to enhance material performance in demanding environments.

Key Differences Between Soft and Hard Burning

Soft burning occurs at lower temperatures, resulting in slower chemical reactions and reduced thermal stress on materials, making it ideal for delicate components or ceramics. Hard burning uses higher temperatures, producing faster sintering and stronger mechanical properties, but with increased risk of cracking or warping. Understanding these key differences helps you select the appropriate firing technique based on material tolerance and desired durability.

Effects on Material Properties: Soft vs Hard Burning

Soft burning results in a porous and less dense ceramic structure, which enhances thermal insulation but reduces mechanical strength and wear resistance. Hard burning produces a dense, high-strength ceramic with superior hardness and durability, improving resistance to abrasion and thermal shock. The choice between soft and hard burning directly affects the final product's performance in applications requiring either flexibility and insulation or toughness and longevity.

Industrial Applications of Soft and Hard Burning

Soft burning techniques are widely used in industrial applications requiring precise control over material properties, such as ceramics manufacturing and heat treatment of metals, due to their lower temperature profiles that minimize thermal stress. Hard burning processes are essential in industries demanding high durability and surface hardness, including tool manufacturing, automotive components, and heavy machinery, where elevated temperatures create superior wear resistance and tensile strength. Selecting between soft and hard burning methods depends on the desired mechanical characteristics and the specific operational environment of the industrial product.

Impact on Efficiency and Energy Consumption

Soft burning reduces energy consumption by maintaining lower furnace temperatures, leading to higher fuel efficiency and less heat loss compared to hard burning. Hard burning, while producing sharper edges in ceramics or metals, requires significantly more energy, decreasing overall process efficiency. Optimizing your process with soft burning techniques can enhance energy savings without sacrificing product quality.

Safety Considerations in Soft and Hard Burning Processes

Soft burning processes typically operate at lower temperatures, reducing the risk of thermal hazards and minimizing the chance of equipment failure due to overheating. Hard burning involves higher temperatures that require stringent safety measures, including robust insulation, precise temperature controls, and protective gear to prevent burns and fires. Proper ventilation and continuous monitoring are essential in both methods to manage potentially hazardous fumes and ensure a safe working environment.

Choosing the Right Burning Method for Your Needs

Soft burning offers a gentler heat ideal for delicate ceramics, reducing the risk of cracks and ensuring smooth finishes, while hard burning utilizes higher temperatures for increased strength and durability in stoneware and porcelain. Selecting the appropriate method depends on the material's composition and desired end-use, with soft burning suited for decorative pieces and hard burning preferred for functional, heavy-use items. Understanding the thermal properties and firing temperatures helps optimize results and prevents damage during the ceramic firing process.

Future Trends in Soft and Hard Burning Technologies

Future trends in soft and hard burning technologies emphasize increased energy efficiency and environmental sustainability through advanced combustion control systems and alternative fuel integration. Innovations in sensor technology and AI-driven monitoring enable precise adjustments in burning processes, optimizing emission reductions and operational costs. Your investment in cutting-edge soft and hard burning solutions ensures alignment with tightening regulatory standards and evolving market demands.

Soft burning vs Hard burning Infographic

libmatt.com

libmatt.com