OPC (Organic Photoconductor) plays a crucial role in laser printers and copiers by transferring toner onto paper using electrostatic charges, while PPC (Primary Photoconductor) refers specifically to the main photoconductive drum that holds the charge in the imaging process. Understanding the differences between OPC and PPC helps you maintain and optimize the performance of your printing devices more effectively.

Table of Comparison

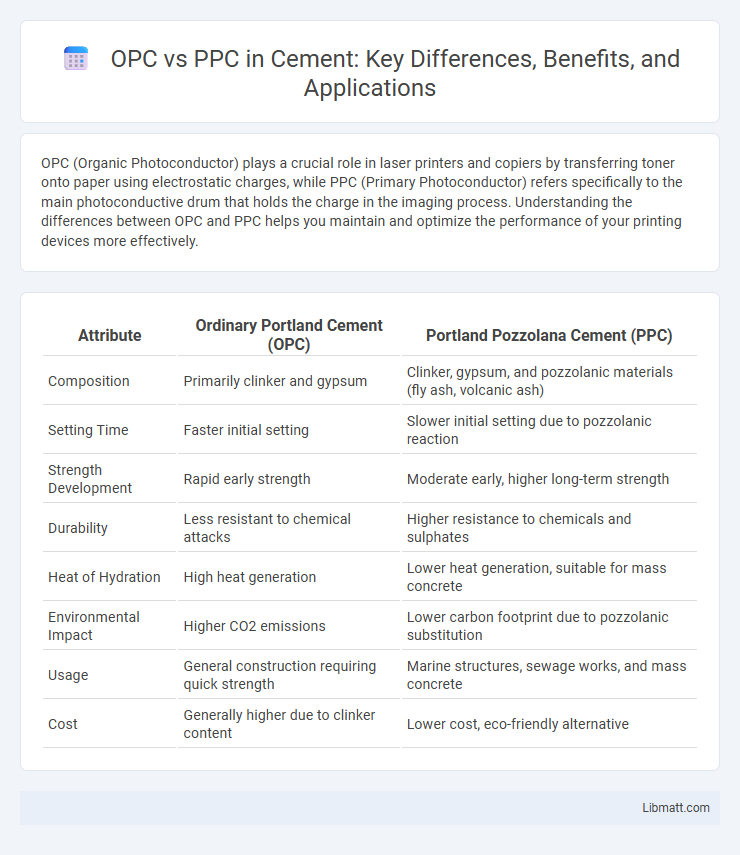

| Attribute | Ordinary Portland Cement (OPC) | Portland Pozzolana Cement (PPC) |

|---|---|---|

| Composition | Primarily clinker and gypsum | Clinker, gypsum, and pozzolanic materials (fly ash, volcanic ash) |

| Setting Time | Faster initial setting | Slower initial setting due to pozzolanic reaction |

| Strength Development | Rapid early strength | Moderate early, higher long-term strength |

| Durability | Less resistant to chemical attacks | Higher resistance to chemicals and sulphates |

| Heat of Hydration | High heat generation | Lower heat generation, suitable for mass concrete |

| Environmental Impact | Higher CO2 emissions | Lower carbon footprint due to pozzolanic substitution |

| Usage | General construction requiring quick strength | Marine structures, sewage works, and mass concrete |

| Cost | Generally higher due to clinker content | Lower cost, eco-friendly alternative |

Introduction to OPC and PPC

OPC (Other People's Content) and PPC (Pay-Per-Click) represent two distinct digital marketing strategies. OPC involves leveraging content created by others to engage audiences and drive traffic, often through sharing or repurposing valuable resources. PPC, on the other hand, is a paid advertising model where advertisers pay a fee each time their ad is clicked, optimizing visibility and targeting specific user intent for immediate results. Your choice between OPC and PPC depends on your marketing goals and budget allocation.

Definition and Composition of OPC

Ordinary Portland Cement (OPC) is a basic type of cement widely used in construction, primarily composed of clinker and a small amount of gypsum. The clinker is produced by heating limestone, clay, and other raw materials in a kiln to form compounds such as tricalcium silicate and dicalcium silicate, which provide cement with its binding properties. Its chemical composition typically includes calcium oxide, silicon dioxide, aluminum oxide, and iron oxide, making it distinct from Portland Pozzolana Cement (PPC), which contains additional pozzolanic materials like fly ash or volcanic ash.

Definition and Composition of PPC

Precipitated Calcium Carbonate (PPC) is a synthetic form of calcium carbonate created by the chemical precipitation process, primarily composed of fine calcium carbonate particles with controlled purity and particle size. Unlike Ordinary Portland Cement (OPC), which is a hydraulic binder made from clinker, gypsum, and other minerals, PPC includes a higher percentage of finely ground calcium carbonate, improving its workability and sustainability. Your construction or manufacturing applications benefit from PPC's enhanced whiteness, consistent particle distribution, and lower environmental impact compared to OPC.

Key Differences between OPC and PPC

OPC (Ordinary Portland Cement) primarily consists of clinker, gypsum, and minor additives, whereas PPC (Pozzolana Portland Cement) incorporates pozzolanic materials such as fly ash or volcanic ash, enhancing its durability and resistance to chemical attacks. OPC sets and hardens faster, making it suitable for quick construction, while PPC exhibits superior long-term strength and reduced permeability, ideal for marine and hydraulic structures. PPC's lower heat of hydration also minimizes thermal cracking compared to OPC, improving structural integrity in massive concrete pours.

Strength and Durability Comparison

OPC (Ordinary Portland Cement) exhibits high compressive strength suitable for general construction, but PPC (Portland Pozzolana Cement) offers improved durability due to its pozzolanic additives, which enhance resistance to chemical attacks and reduce permeability. PPC's slower strength gain provides better long-term performance in harsh environments, making it ideal for structures exposed to sulfate and chloride-rich conditions. Your choice between OPC and PPC should consider the specific structural demands and environmental exposure for optimal strength and durability.

Applications and Uses of OPC

OPC (Ordinary Portland Cement) is extensively used in general construction projects such as residential buildings, bridges, roads, and precast concrete products due to its balanced strength and durability. It is ideal for applications requiring moderate resistance to chemical attacks and weather conditions, making it suitable for foundations, plastering, and flooring. Compared to PPC (Pozzolana Portland Cement), OPC offers faster setting times and higher initial strength, which is critical in time-sensitive construction work.

Applications and Uses of PPC

Polypropylene carbonate (PPC) is widely used in packaging, adhesives, and coatings due to its biodegradability and excellent gas barrier properties. Its applications extend to medical devices and drug delivery systems where biocompatibility and controlled degradation are critical. Compared to OPC (ordinary Portland cement), PPC's versatility in eco-friendly materials makes it a preferred choice for sustainable product development.

Environmental Impact: OPC vs PPC

Portland Pozzolana Cement (PPC) significantly reduces carbon dioxide emissions compared to Ordinary Portland Cement (OPC) due to its use of fly ash, a byproduct from thermal power plants, which lowers the clinker content and energy consumption during production. OPC manufacturing involves higher limestone calcination, releasing more CO2, making PPC a more eco-friendly choice for sustainable construction projects. Your selection of PPC can contribute to decreased environmental impact and promote greener building practices.

Cost Comparison of OPC and PPC

Ordinary Portland Cement (OPC) generally has a lower initial cost compared to Portland Pozzolana Cement (PPC) due to simpler production processes and readily available raw materials. PPC, while slightly more expensive upfront, offers long-term savings by enhancing durability and reducing maintenance costs in concrete structures. Choosing PPC can improve your project's lifecycle cost efficiency despite the higher initial price.

Which is Better: OPC or PPC?

OPC (Ordinary Portland Cement) offers higher early strength and rapid setting, making it ideal for structural applications requiring quick load-bearing capacity. PPC (Portland Pozzolana Cement) enhances durability and resistance to chemical attacks through added pozzolanic materials, suitable for long-term projects exposed to harsh environments. Your choice depends on project requirements, prioritizing OPC for speed and strength or PPC for longevity and environmental resistance.

OPC vs PPC Infographic

libmatt.com

libmatt.com