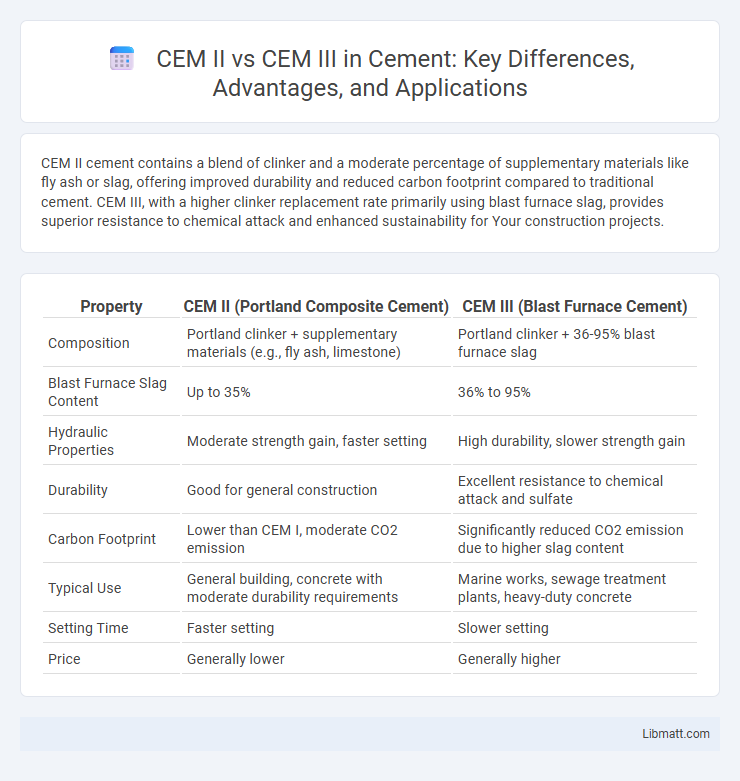

CEM II cement contains a blend of clinker and a moderate percentage of supplementary materials like fly ash or slag, offering improved durability and reduced carbon footprint compared to traditional cement. CEM III, with a higher clinker replacement rate primarily using blast furnace slag, provides superior resistance to chemical attack and enhanced sustainability for Your construction projects.

Table of Comparison

| Property | CEM II (Portland Composite Cement) | CEM III (Blast Furnace Cement) |

|---|---|---|

| Composition | Portland clinker + supplementary materials (e.g., fly ash, limestone) | Portland clinker + 36-95% blast furnace slag |

| Blast Furnace Slag Content | Up to 35% | 36% to 95% |

| Hydraulic Properties | Moderate strength gain, faster setting | High durability, slower strength gain |

| Durability | Good for general construction | Excellent resistance to chemical attack and sulfate |

| Carbon Footprint | Lower than CEM I, moderate CO2 emission | Significantly reduced CO2 emission due to higher slag content |

| Typical Use | General building, concrete with moderate durability requirements | Marine works, sewage treatment plants, heavy-duty concrete |

| Setting Time | Faster setting | Slower setting |

| Price | Generally lower | Generally higher |

Introduction to Cement Types: CEM II and CEM III

CEM II, or Portland-composite cement, contains 65-79% clinker combined with supplementary materials like slag, fly ash, or limestone, enhancing durability and sustainability in construction. CEM III, known as blast furnace cement, consists of 35-64% clinker and a higher proportion of granulated blast furnace slag, offering superior resistance to chemical attacks and reduced CO2 emissions. Understanding these differences helps you select the optimal cement type for your project's environmental impact and performance requirements.

Composition and Manufacturing Differences

CEM II, commonly known as Portland-composite cement, contains 65-79% clinker blended with supplementary materials such as fly ash, slag, or limestone, enhancing durability and reducing carbon footprint. CEM III, or blast furnace cement, features a significantly higher proportion of ground granulated blast furnace slag (GGBFS), ranging from 66-95%, which improves sulfate resistance and long-term strength. Understanding these composition and manufacturing differences helps you select the appropriate cement type for specific construction needs and environmental considerations.

Key Physical Properties Comparison

CEM II (Portland-composite cement) typically contains 65-80% clinker and exhibits moderate strength development with good durability, making it suitable for general construction. CEM III (blast furnace cement) includes 35-65% clinker and a high proportion of blast furnace slag, resulting in enhanced resistance to chemical attacks and lower heat of hydration, ideal for large-scale infrastructure projects. Your choice between CEM II and CEM III will depend on the specific performance requirements such as strength, durability, and environmental conditions.

Strength Development: CEM II vs CEM III

CEM II, also known as Portland-composite cement, typically achieves higher early strength due to its lower replacement rate of clinker by supplementary materials compared to CEM III. CEM III, or blast furnace cement, contains a larger proportion of ground granulated blast furnace slag, which slows early strength development but enhances long-term durability and strength beyond 28 days. Consequently, CEM II is preferred for projects requiring rapid strength gain, while CEM III suits applications prioritizing long-term performance and sulfate resistance.

Durability and Long-Term Performance

CEM II cement offers moderate durability and long-term performance suitable for general construction, while CEM III provides superior resistance to chemical attacks, sulfate exposure, and chloride ingress, enhancing the lifespan of structures in aggressive environments. The higher slag content in CEM III significantly improves concrete density and reduces permeability, contributing to better protection against corrosion and deterioration over time. Choosing CEM III allows you to ensure enhanced durability and structural integrity for projects requiring robust long-term performance.

Environmental Impact and Sustainability

CEM II cement, also known as Portland-composite cement, incorporates a mix of clinker and supplementary materials like fly ash or slag, reducing CO2 emissions by approximately 20-30% compared to traditional Portland cement. CEM III, classified as blast furnace cement, contains a higher proportion of ground granulated blast furnace slag, which can reduce carbon emissions by up to 50-60%, making it more sustainable for environmentally conscious construction projects. Choosing CEM III for Your building needs significantly lowers Your project's carbon footprint, promoting better sustainability practices in the construction industry.

Typical Applications in Construction

CEM II, known as Portland-composite cement, is commonly used in general construction projects such as residential buildings, precast concrete, and infrastructure works due to its balanced strength and durability. CEM III, or blast furnace cement, is preferred for heavy-duty applications like marine structures, sewage treatment plants, and high-performance concrete because of its superior resistance to chemical attack and sulfate exposure. Choosing the right cement type ensures your construction project meets the necessary strength and environmental durability requirements efficiently.

Cost Considerations and Economic Benefits

CEM II cement, containing 5-20% supplementary materials such as fly ash or limestone, offers cost savings by reducing clinker content, which lowers production expenses and carbon emissions. CEM III, with a higher percentage of blast furnace slag (above 66%), typically has a lower price due to reduced clinker use and benefits from enhanced durability, leading to long-term economic advantages in infrastructure projects. Choosing between CEM II and CEM III depends on your specific project requirements and budget, as CEM III may provide greater savings in large-scale applications with its improved lifespan and reduced maintenance costs.

Standards and Regulatory Requirements

CEM II and CEM III are classified under the European standard EN 197-1 for common cements, with CEM II defined as Portland-composite cement containing 5-35% mineral additions, and CEM III as blast furnace cement with 36-95% ground granulated blast furnace slag (GGBFS). Regulatory requirements mandate specific performance criteria such as strength classes, setting times, and chemical compositions, ensuring each cement type meets environmental and durability standards for various construction applications. Compliance with EN 197-1 facilitates appropriate selection of CEM II for moderate sulfate resistance and CEM III for enhanced durability in aggressive environments.

Choosing Between CEM II and CEM III

Choosing between CEM II and CEM III depends on specific construction requirements, with CEM II offering a blend of Portland cement and supplementary materials like fly ash or slag, providing moderate strength and durability. CEM III contains a higher proportion of blast furnace slag, resulting in superior resistance to chemical attack and enhanced durability in aggressive environments. For projects demanding long-term performance and sustainability, especially in marine or industrial settings, CEM III is preferred, whereas CEM II suits general construction applications needing balanced cost and performance.

CEM II vs CEM III Infographic

libmatt.com

libmatt.com