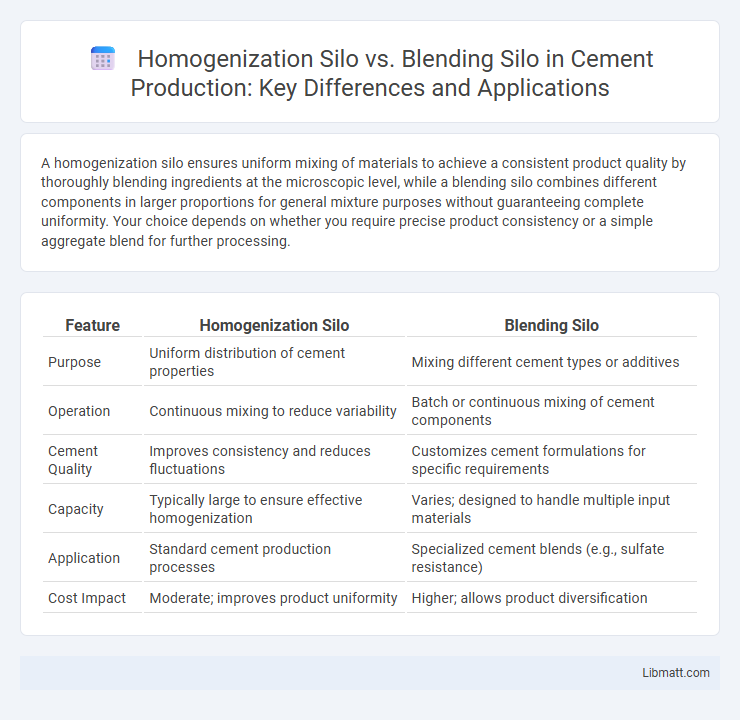

A homogenization silo ensures uniform mixing of materials to achieve a consistent product quality by thoroughly blending ingredients at the microscopic level, while a blending silo combines different components in larger proportions for general mixture purposes without guaranteeing complete uniformity. Your choice depends on whether you require precise product consistency or a simple aggregate blend for further processing.

Table of Comparison

| Feature | Homogenization Silo | Blending Silo |

|---|---|---|

| Purpose | Uniform distribution of cement properties | Mixing different cement types or additives |

| Operation | Continuous mixing to reduce variability | Batch or continuous mixing of cement components |

| Cement Quality | Improves consistency and reduces fluctuations | Customizes cement formulations for specific requirements |

| Capacity | Typically large to ensure effective homogenization | Varies; designed to handle multiple input materials |

| Application | Standard cement production processes | Specialized cement blends (e.g., sulfate resistance) |

| Cost Impact | Moderate; improves product uniformity | Higher; allows product diversification |

Understanding Homogenization Silos

Homogenization silos ensure a consistent product quality by mixing materials thoroughly to achieve uniformity in composition, particle size, and moisture content. Unlike blending silos that combine different raw materials, homogenization silos focus on reducing variations within a single batch to optimize downstream processing efficiency. Understanding homogenization silos is crucial for maintaining product stability and enhancing your production control.

Key Features of Blending Silos

Blending silos are designed to combine multiple raw materials or components into a uniform mixture with precise control over composition, ensuring consistent product quality. Key features include advanced agitators or mixers to maintain homogeneity, adjustable feed systems for different input ratios, and sensors for monitoring moisture content and temperature. These silos optimize production efficiency by reducing segregation and enabling customizable blends tailored to specific manufacturing requirements.

Primary Functions and Applications

Homogenization silos ensure uniform consistency by mixing and blending product batches to eliminate variations in texture, color, and composition, making them ideal for industries like food processing and pharmaceuticals where product quality and consistency are critical. Blending silos primarily combine different raw materials or ingredients to create a homogeneous mixture before further production, commonly used in sectors such as cement manufacturing, chemicals, and plastics. Both silos optimize production efficiency by maintaining product integrity, but homogenization silos focus on equalizing finished goods while blending silos emphasize initial ingredient combination.

Technical Differences: Homogenization vs Blending

Homogenization silos employ high-shear mixing technology to create a uniform product by breaking down particles and distributing them evenly at a microscopic level, ensuring consistent texture and composition. Blending silos use mechanical agitation or rotational mixing to combine different materials or batches without altering the particle size or microstructure, focusing on achieving a homogeneous mixture at a macro scale. The key technical difference lies in homogenization's ability to alter physical properties for uniformity versus blending's role in combining ingredients while preserving their original characteristics.

Material Flow Mechanisms Explained

Homogenization silos use continuous mixing and recirculation of materials to ensure uniform quality by breaking down material strata through internal flow patterns. Blending silos rely on layered stacking and sequential discharge to achieve a consistent blend by combining different materials without internal mixing mechanisms. Understanding these material flow mechanisms helps you choose the optimal silo type for uniformity and process efficiency in bulk storage.

Advantages of Homogenization Silos

Homogenization silos ensure consistent product quality by thoroughly mixing materials to minimize variations in composition, which enhances process stability and product reliability. They allow for improved inventory management by creating a uniform blend that simplifies production planning and reduces batch-to-batch inconsistencies. Your operation benefits from increased efficiency and better control over raw material parameters compared to blending silos, which typically only combine materials without thorough mixing.

Benefits of Blending Silos

Blending silos provide enhanced flexibility by allowing precise mixing of different raw materials, ensuring consistent product quality and tailored formulations. They improve operational efficiency through automated control systems that reduce manual intervention and minimize material segregation. This results in better inventory management, cost savings, and higher production throughput compared to homogenization silos.

Industry Use Cases and Suitability

Homogenization silos are essential in the cement and mining industries for ensuring consistent material quality by thoroughly mixing raw materials to achieve uniform composition before processing. Blending silos are widely used in the food and chemical industries to combine multiple ingredients while maintaining separate ingredient properties for customized product formulation. Choosing between homogenization and blending silos depends on the need for either material uniformity or ingredient segregation tailored to specific industrial processes.

Factors to Consider When Choosing a Silo

Factors to consider when choosing between a homogenization silo and a blending silo include the material type, particle size distribution, and the desired uniformity of the final product. Homogenization silos provide consistent mixing for fine powders and ensure product uniformity, while blending silos are better suited for mixing different raw materials with varied properties. Your choice should also account for production volume, mixing time, and ease of maintenance to optimize operational efficiency.

Summary: Homogenization Silo vs Blending Silo

Homogenization silos ensure consistent product quality by thoroughly mixing ingredients at a molecular level, preventing segregation and improving uniformity. Blending silos combine multiple bulk materials to create a homogeneous mixture, optimizing material properties for specific production requirements. Your choice between the two depends on whether you need fine-scale uniformity or bulk material blending for manufacturing processes.

Homogenization Silo vs Blending Silo Infographic

libmatt.com

libmatt.com