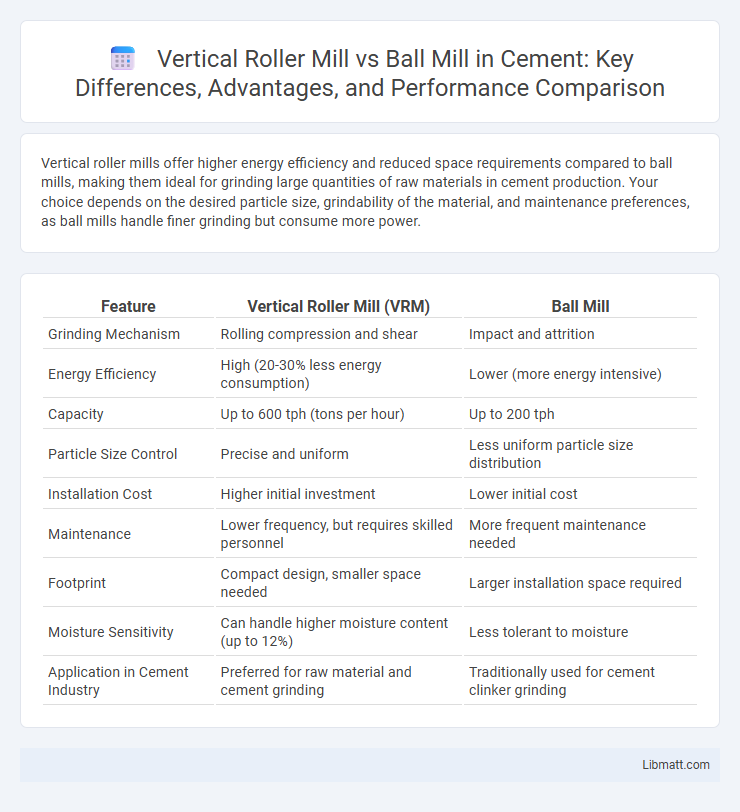

Vertical roller mills offer higher energy efficiency and reduced space requirements compared to ball mills, making them ideal for grinding large quantities of raw materials in cement production. Your choice depends on the desired particle size, grindability of the material, and maintenance preferences, as ball mills handle finer grinding but consume more power.

Table of Comparison

| Feature | Vertical Roller Mill (VRM) | Ball Mill |

|---|---|---|

| Grinding Mechanism | Rolling compression and shear | Impact and attrition |

| Energy Efficiency | High (20-30% less energy consumption) | Lower (more energy intensive) |

| Capacity | Up to 600 tph (tons per hour) | Up to 200 tph |

| Particle Size Control | Precise and uniform | Less uniform particle size distribution |

| Installation Cost | Higher initial investment | Lower initial cost |

| Maintenance | Lower frequency, but requires skilled personnel | More frequent maintenance needed |

| Footprint | Compact design, smaller space needed | Larger installation space required |

| Moisture Sensitivity | Can handle higher moisture content (up to 12%) | Less tolerant to moisture |

| Application in Cement Industry | Preferred for raw material and cement grinding | Traditionally used for cement clinker grinding |

Introduction to Vertical Roller Mill and Ball Mill

Vertical roller mills (VRMs) and ball mills are both widely used grinding equipment in cement and mineral processing industries, with VRMs employing large rollers to crush materials through pressure on a rotating table, whereas ball mills use steel balls in a rotating cylinder for tumbling and grinding. VRMs offer high energy efficiency, reduced power consumption up to 30-40%, and compact design compared to the ball mills that require more space and typically consume higher energy. The choice between vertical roller mill and ball mill depends on material hardness, moisture content, and desired fineness, with VRMs being preferred for drying and grinding simultaneously.

Key Design Differences

Vertical roller mills feature a grinding table and rollers that apply pressure to crush materials, enabling simultaneous grinding, drying, and classification within a single unit. Ball mills utilize rotating drums filled with steel balls, relying on impact and attrition to grind materials primarily through tumbling action. Vertical roller mills generally offer higher energy efficiency and reduced footprint compared to the larger, more maintenance-intensive ball mills.

Energy Efficiency Comparison

Vertical roller mills consume 20-30% less energy than ball mills by grinding materials using pressure and shear forces, which reduces power consumption and increases grinding efficiency. Ball mills rely on tumbling motion and impact to crush materials, often requiring more energy for the same output fineness compared to the vertical roller mill. Selecting a vertical roller mill can enhance your plant's energy efficiency and lower operational costs due to its optimized grinding mechanism.

Grinding Performance and Particle Size Distribution

Vertical roller mills deliver superior grinding performance by utilizing rollers that compress and shear materials, resulting in higher energy efficiency and finer particle size distribution compared to ball mills. The vertical roller mill's ability to produce uniform, finely ground particles enhances your process consistency, especially in cement and mineral grinding applications. In contrast, ball mills typically generate coarser particles with a wider size distribution due to their tumbling motion, making vertical roller mills better suited for achieving precise particle size control.

Operational and Maintenance Requirements

Vertical roller mills demand less maintenance due to fewer moving parts and integrated grinding, drying, and separating functions, resulting in lower operational costs compared to ball mills. Ball mills require frequent liner replacements and more intensive maintenance schedules to manage wear and grinding media consumption. Your choice affects downtime, labor intensity, and overall plant efficiency based on the ease of access and complexity of maintenance tasks associated with each mill type.

Installation and Space Requirements

Vertical roller mills require less installation time and space due to their compact design and integrated grinding, drying, and separating functions within a single unit. Ball mills occupy larger floor area and involve more complex installation processes because of the need for separate components like grinding shells, gears, and classifiers. The efficient footprint of vertical roller mills leads to reduced structural support and foundation requirements, making them suitable for limited-space environments.

Application Areas and Material Suitability

Vertical roller mills excel in grinding materials with medium to high hardness and moisture content, making them ideal for cement clinker, slag, and coal in cement and power plants. Ball mills are better suited for fine grinding applications involving softer materials like minerals, ores, and chemicals, offering versatility across mining and chemical industries. Your choice between these mills should align with material characteristics and specific application requirements for optimal performance.

Environmental Impact and Sustainability

Vertical roller mills consume significantly less energy and produce lower CO2 emissions compared to ball mills, enhancing environmental sustainability in mineral grinding processes. The design of vertical roller mills allows for more efficient material grinding and better dust control, reducing airborne pollutants and minimizing waste. Your choice of a vertical roller mill supports greener manufacturing practices by lowering ecological footprints and promoting resource conservation.

Cost Analysis: CapEx vs OpEx

Vertical roller mills typically have higher initial capital expenditure (CapEx) due to advanced technology and complex installation requirements, but they offer significantly lower operational expenditure (OpEx) through energy-efficient grinding and reduced maintenance costs. Ball mills have lower upfront CapEx but incur higher OpEx because of greater energy consumption and more frequent maintenance needs. Evaluating lifecycle costs reveals that vertical roller mills often provide better cost efficiency in large-scale, continuous grinding operations.

Summary and Future Trends in Milling Technology

Vertical roller mills offer higher energy efficiency and reduced operational costs compared to traditional ball mills, making them ideal for large-scale cement and mineral processing. Future trends in milling technology emphasize automation, digital control systems, and the integration of AI for optimized performance and predictive maintenance. Your investment in cutting-edge vertical roller mills can enhance productivity while minimizing environmental impact.

Vertical roller mill vs Ball mill Infographic

libmatt.com

libmatt.com