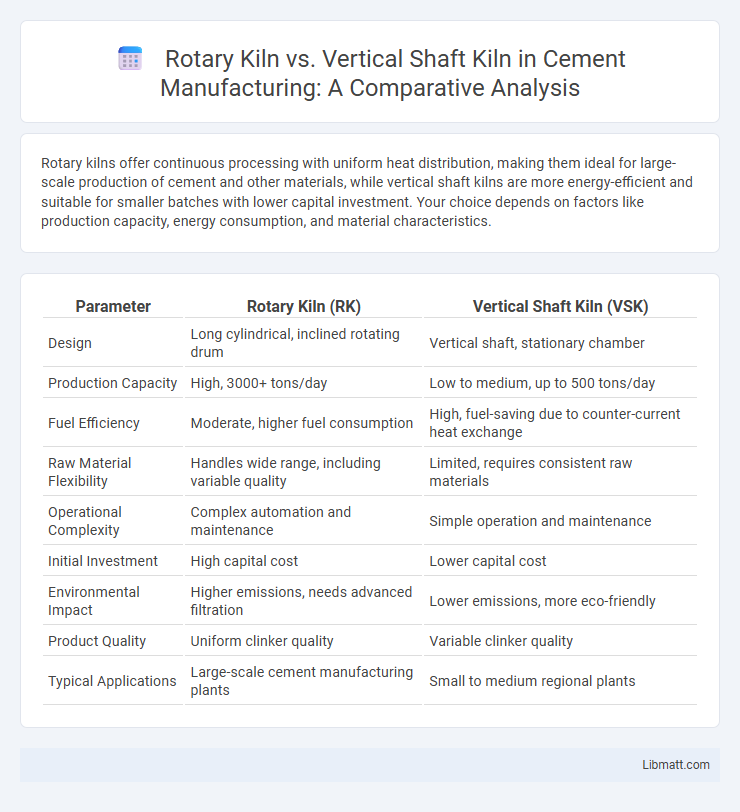

Rotary kilns offer continuous processing with uniform heat distribution, making them ideal for large-scale production of cement and other materials, while vertical shaft kilns are more energy-efficient and suitable for smaller batches with lower capital investment. Your choice depends on factors like production capacity, energy consumption, and material characteristics.

Table of Comparison

| Parameter | Rotary Kiln (RK) | Vertical Shaft Kiln (VSK) |

|---|---|---|

| Design | Long cylindrical, inclined rotating drum | Vertical shaft, stationary chamber |

| Production Capacity | High, 3000+ tons/day | Low to medium, up to 500 tons/day |

| Fuel Efficiency | Moderate, higher fuel consumption | High, fuel-saving due to counter-current heat exchange |

| Raw Material Flexibility | Handles wide range, including variable quality | Limited, requires consistent raw materials |

| Operational Complexity | Complex automation and maintenance | Simple operation and maintenance |

| Initial Investment | High capital cost | Lower capital cost |

| Environmental Impact | Higher emissions, needs advanced filtration | Lower emissions, more eco-friendly |

| Product Quality | Uniform clinker quality | Variable clinker quality |

| Typical Applications | Large-scale cement manufacturing plants | Small to medium regional plants |

Introduction to Rotary Kiln and Vertical Shaft Kiln

Rotary Kilns feature a large, cylindrical, rotating drum that processes raw materials through continuous heating, commonly used in cement production for its high capacity and uniform product quality. Vertical Shaft Kilns consist of a vertical, stationary structure where materials move downward through preheated zones, making them energy-efficient and suitable for small to medium-scale operations. Your choice between the two depends on factors like production volume, energy consumption, and material feed characteristics.

Design and Operational Principles

Rotary kilns feature a cylindrical, rotating design that allows continuous material processing through controlled heat and residence time, optimizing thermal efficiency for cement and lime production. Vertical shaft kilns operate on a counter-current principle where raw materials descend through a vertical shaft while hot gases rise, enabling energy-efficient calcination with shorter retention times. The rotary kiln's rotating motion promotes uniform heat distribution, whereas the vertical shaft kiln relies on gravity-driven material flow and staged temperature zones for combustion and preheating.

Key Differences in Construction

Rotary kilns feature a cylindrical, rotating steel shell lined with refractory materials, allowing continuous processing of materials through gradual heating. Vertical shaft kilns consist of a stationary vertical shaft where raw material moves downward by gravity while heat rises, offering a more compact and energy-efficient design. Your choice depends on factors like production scale, fuel efficiency, and raw material characteristics crucial for optimal kiln performance.

Energy Efficiency Comparison

Rotary kilns typically consume more fuel due to their longer retention times and higher thermal mass, while vertical shaft kilns are designed to optimize heat exchange, resulting in improved energy efficiency with lower fuel consumption. Vertical shaft kilns use counter-current heat transfer, allowing Your process to capture and reuse heat more effectively, reducing overall energy requirements. Choosing a vertical shaft kiln can significantly cut operating costs and carbon emissions compared to rotary kilns.

Product Quality and Consistency

Rotary kilns provide superior product quality and consistency due to their continuous rotation and uniform heat distribution, which ensures thorough material processing and homogenous clinker formation. Vertical shaft kilns, while energy-efficient, often result in variable product quality because of uneven temperature zones and limited control over residence time. Your choice between the two should prioritize rotary kilns for high-grade, consistent cement or lime production.

Environmental Impact Assessment

Rotary Kilns typically produce higher CO2 emissions due to their larger fuel consumption and longer process times, whereas Vertical Shaft Kilns (VSK) are more energy-efficient, resulting in lower greenhouse gas outputs. Your environmental impact assessment should consider the particulate emissions, with rotary kilns generating more dust and NOx pollutants compared to the relatively cleaner operation of VSKs. Choosing a Vertical Shaft Kiln can significantly reduce your facility's carbon footprint and contribute to more sustainable cement production.

Maintenance and Operating Costs

Rotary kilns generally incur higher maintenance and operating costs due to their complex mechanical parts, including gears, tyres, and bearings that require frequent inspection and lubrication. Vertical shaft kilns offer lower maintenance expenses because of their simpler design and fewer moving components, resulting in reduced downtime and labor costs. Your choice between the two will significantly impact long-term operational budgets, with vertical shaft kilns being more cost-effective for smaller-scale production.

Suitability for Various Materials

Rotary kilns are ideal for processing a wide range of materials including cement clinker, lime, and refractories due to their robust design and ability to handle high-temperature reactions. Vertical shaft kilns are better suited for materials like quicklime and certain types of aggregates where continuous operation and energy efficiency are critical. Your choice depends on the specific material properties and production requirements to ensure optimal kiln performance and product quality.

Scalability and Throughput Capacity

Rotary kilns offer superior scalability and higher throughput capacity, making them ideal for large-scale industrial applications requiring continuous processing of bulk materials. Vertical shaft kilns, with their more compact design, cater to smaller production volumes and have limited throughput capacity, which restricts scalability for extensive operations. The choice between rotary and vertical shaft kilns largely depends on production scale needs and material handling requirements.

Industry Applications and Use Cases

Rotary kilns are extensively used in cement production, lime calcination, and metallurgical industries due to their capacity for processing large volumes and handling diverse raw materials. Vertical shaft kilns find primary application in the manufacturing of clinker and quicklime, especially in small to medium batch operations requiring energy efficiency and lower emissions. Both kiln types serve critical roles in the construction and chemical industries, with rotary kilns favored for continuous high-temperature processing and vertical shaft kilns preferred for modular, space-saving installations.

Rotary Kiln vs Vertical Shaft Kiln Infographic

libmatt.com

libmatt.com