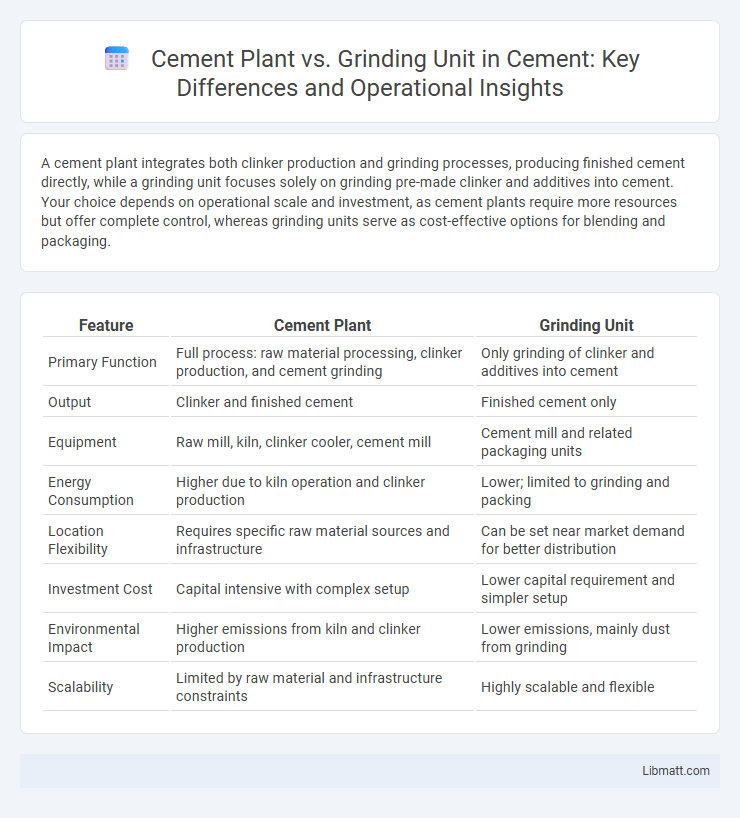

A cement plant integrates both clinker production and grinding processes, producing finished cement directly, while a grinding unit focuses solely on grinding pre-made clinker and additives into cement. Your choice depends on operational scale and investment, as cement plants require more resources but offer complete control, whereas grinding units serve as cost-effective options for blending and packaging.

Table of Comparison

| Feature | Cement Plant | Grinding Unit |

|---|---|---|

| Primary Function | Full process: raw material processing, clinker production, and cement grinding | Only grinding of clinker and additives into cement |

| Output | Clinker and finished cement | Finished cement only |

| Equipment | Raw mill, kiln, clinker cooler, cement mill | Cement mill and related packaging units |

| Energy Consumption | Higher due to kiln operation and clinker production | Lower; limited to grinding and packing |

| Location Flexibility | Requires specific raw material sources and infrastructure | Can be set near market demand for better distribution |

| Investment Cost | Capital intensive with complex setup | Lower capital requirement and simpler setup |

| Environmental Impact | Higher emissions from kiln and clinker production | Lower emissions, mainly dust from grinding |

| Scalability | Limited by raw material and infrastructure constraints | Highly scalable and flexible |

Introduction to Cement Plants and Grinding Units

Cement plants are large-scale industrial facilities where raw materials such as limestone, clay, and gypsum are processed through stages including crushing, blending, and clinker production using a rotary kiln. Grinding units, also known as cement grinding mills, focus primarily on the final stage of cement production by finely grinding clinker with additives to produce the finished cement powder. While cement plants handle the entire production process from raw material to clinker and finished product, grinding units typically process clinker brought from separate cement plants, optimizing production efficiency and flexibility.

Key Differences Between Cement Plants and Grinding Units

Cement plants perform comprehensive manufacturing processes, including raw material preparation, clinker production in kilns, and final cement grinding, while grinding units focus solely on processing clinker into fine cement powder. Cement plants require large-scale infrastructure and energy consumption due to their multi-stage operations, whereas grinding units have lower capital and operational costs with simpler equipment. The output from cement plants can vary in type and composition, whereas grinding units primarily produce ready-to-use cement by blending clinker with additives like gypsum.

Production Processes: An Overview

Cement plants integrate raw material preparation, clinker production, and cement grinding into a continuous process, converting limestone and other materials into clinker through calcination and then grinding it into cement. Grinding units focus solely on the final stage, where pre-produced clinker is finely ground with additives like gypsum to produce different cement types. The distinction lies in the comprehensive clinker production at cement plants versus the exclusive grinding and blending operations at grinding units, impacting overall production efficiency and product flexibility.

Raw Material Requirements and Sourcing

Cement plants require a wide range of raw materials such as limestone, clay, and iron ore, sourced from large quarries to ensure consistent supply for clinker production. Grinding units primarily use clinker and additives like gypsum, which are easier to source and transport compared to raw materials for cement manufacturing. You should consider the complexity of raw material sourcing when choosing between the two, as cement plants demand extensive quarrying operations while grinding units focus on procuring finished clinker and supplementary materials.

Energy Consumption and Efficiency

Cement plants typically consume significantly more energy than grinding units due to the extensive processes involved in clinker production, including raw material extraction, grinding, and high-temperature kiln operation. Grinding units specialize in pulverizing clinker into fine cement powder, which requires less thermal energy and thus exhibits higher energy efficiency per ton of output. Optimizing grinding unit operations can lead to substantial energy savings, reducing overall carbon emissions in cement production.

Environmental Impact and Sustainability

Cement plants typically generate higher greenhouse gas emissions and particulate matter due to clinker production, impacting air quality and contributing to climate change. Grinding units, responsible for crushing and grinding raw materials or cement clinker, have a comparatively lower environmental footprint but still consume significant energy and produce dust. Optimizing Your grinding processes and integrating alternative fuels in both units enhance sustainability by reducing CO2 emissions and minimizing resource depletion.

Investment Costs and Economic Considerations

Cement plants require significantly higher investment costs compared to grinding units due to their complex production processes involving clinker production, raw material handling, and energy consumption. Grinding units focus mainly on pulverizing clinker and gypsum, resulting in lower capital expenditure and reduced operational costs. Economically, grinding units offer flexibility in location and quicker payback periods, making them attractive for market-specific cement production and cost-sensitive regions.

Operational Challenges and Maintenance Needs

Cement plants face complex operational challenges such as high energy consumption, raw material variability, and extensive equipment wear, demanding rigorous process monitoring and maintenance of kilns, crushers, and conveyors to ensure consistent clinker quality. Grinding units primarily encounter challenges related to particle size control, heat generation, and grinding media wear, requiring frequent maintenance of mills, separators, and ventilation systems to maintain grinding efficiency and product fineness. Both facilities necessitate proactive maintenance strategies, including predictive analytics and condition-based monitoring, to minimize downtime and optimize overall production performance.

End Product Quality and Applications

Cement plants produce clinker and finish it into cement, ensuring higher control over end product quality with consistent chemical composition and strength, ideal for structural concrete applications. Grinding units primarily focus on pulverizing clinker into cement, often relying on external clinker supply, which may limit control over the final product's performance characteristics. Consequently, cement from integrated plants suits critical construction projects requiring durability, while grinding units efficiently supply cement for general applications with varying quality demands.

Choosing Between a Cement Plant and a Grinding Unit

Choosing between a cement plant and a grinding unit depends on production capacity, raw material availability, and investment costs. A cement plant integrates clinker production and grinding, offering higher control over quality but requires significant capital and resources. Your decision should consider market demand, logistics, and environmental regulations to optimize operational efficiency and profitability.

Cement plant vs Grinding unit Infographic

libmatt.com

libmatt.com