Carbon capture utilization in the cement industry focuses on converting captured CO2 into valuable products such as fuels or chemicals, enhancing sustainability and reducing emissions. Your choice between utilization and storage depends on whether you prioritize immediate emission reduction through long-term underground storage or innovative carbon recycling within cement production.

Table of Comparison

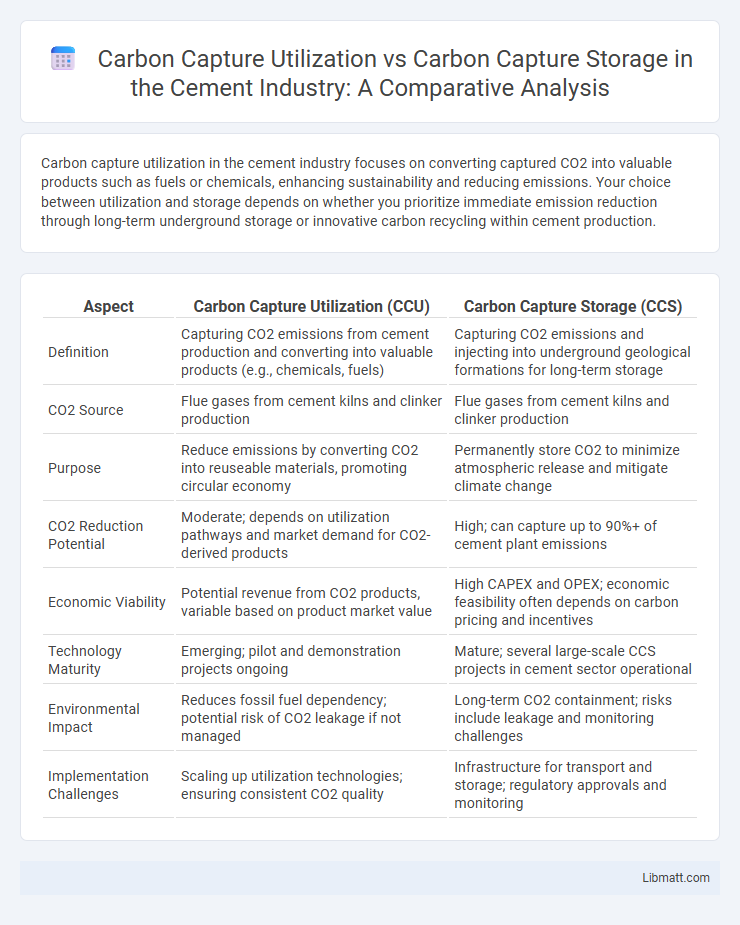

| Aspect | Carbon Capture Utilization (CCU) | Carbon Capture Storage (CCS) |

|---|---|---|

| Definition | Capturing CO2 emissions from cement production and converting into valuable products (e.g., chemicals, fuels) | Capturing CO2 emissions and injecting into underground geological formations for long-term storage |

| CO2 Source | Flue gases from cement kilns and clinker production | Flue gases from cement kilns and clinker production |

| Purpose | Reduce emissions by converting CO2 into reuseable materials, promoting circular economy | Permanently store CO2 to minimize atmospheric release and mitigate climate change |

| CO2 Reduction Potential | Moderate; depends on utilization pathways and market demand for CO2-derived products | High; can capture up to 90%+ of cement plant emissions |

| Economic Viability | Potential revenue from CO2 products, variable based on product market value | High CAPEX and OPEX; economic feasibility often depends on carbon pricing and incentives |

| Technology Maturity | Emerging; pilot and demonstration projects ongoing | Mature; several large-scale CCS projects in cement sector operational |

| Environmental Impact | Reduces fossil fuel dependency; potential risk of CO2 leakage if not managed | Long-term CO2 containment; risks include leakage and monitoring challenges |

| Implementation Challenges | Scaling up utilization technologies; ensuring consistent CO2 quality | Infrastructure for transport and storage; regulatory approvals and monitoring |

Introduction to Carbon Capture in the Cement Industry

Carbon capture in the cement industry targets the significant CO2 emissions produced during limestone calcination and fuel combustion, addressing nearly 7% of global carbon dioxide output. Carbon Capture Utilization (CCU) transforms captured CO2 into valuable products like synthetic fuels, chemicals, or construction materials, fostering circular economy principles. Carbon Capture Storage (CCS) sequesters CO2 in geological formations, ensuring long-term emission reduction without immediate product generation, making your sustainability efforts critical to climate impact mitigation.

Understanding Carbon Capture Utilization (CCU)

Carbon Capture Utilization (CCU) in the cement industry involves converting captured CO2 into valuable products such as synthetic fuels, chemicals, or building materials, reducing overall emissions. Unlike Carbon Capture Storage (CCS), which permanently stores CO2 underground, CCU offers a circular approach by reusing CO2 within the industrial processes, enhancing resource efficiency. Understanding how CCU integrates with cement production can help optimize your facility's environmental footprint while creating economic opportunities from captured carbon.

Exploring Carbon Capture Storage (CCS) Methods

Carbon Capture Storage (CCS) methods in the cement industry involve capturing CO2 emissions from production processes and securely storing them underground in geological formations such as depleted oil and gas fields or deep saline aquifers. Compared to Carbon Capture Utilization (CCU), which repurposes CO2 for products like chemicals or fuels, CCS offers a more permanent solution to reduce atmospheric carbon by preventing emissions from entering the air. Your choice of CCS technology can significantly impact the cement sector's carbon footprint, making the selection of efficient capture and storage techniques crucial for meeting climate goals.

Key Technologies for CCU and CCS in Cement Production

Carbon Capture Utilization (CCU) in cement production primarily involves technologies that convert captured CO2 into valuable products such as synthetic fuels, chemicals, or building materials, leveraging processes like mineralization or chemical catalysis. Carbon Capture Storage (CCS) focuses on capturing CO2 emissions from cement plants and securely injecting them into geological formations for long-term storage, utilizing technologies such as post-combustion capture with amine solvents and deep saline aquifers or depleted oil reservoirs for sequestration. Your choice between CCU and CCS depends on factors like economic viability, infrastructure availability, and regulatory support within the cement industry.

Comparative Analysis: CCU vs CCS for Cement Plants

Carbon Capture Utilization (CCU) offers cement plants the advantage of converting captured CO2 into value-added products like concrete additives, fuels, or chemicals, enabling a circular carbon economy and potential revenue streams. Carbon Capture Storage (CCS), on the other hand, focuses on permanently sequestering CO2 in geological formations, providing a more established method of emission reduction but without direct economic benefit from byproducts. Your choice between CCU and CCS depends on factors such as cost-effectiveness, regulatory incentives, and the availability of utilization markets versus suitable storage sites near the cement plant.

Benefits of Carbon Capture Utilization for Cement Manufacturers

Carbon Capture Utilization (CCU) offers cement manufacturers significant benefits by converting captured CO2 into valuable products like synthetic aggregates and fuels, reducing overall carbon emissions embedded in cement production. This approach enhances sustainability while creating new revenue streams, strengthening the industry's circular economy. Your adoption of CCU technologies can improve environmental compliance and reduce dependency on carbon storage solutions, which often involve long-term monitoring and potential leakage risks.

Challenges and Limitations of Carbon Capture Storage

Carbon capture storage (CCS) in the cement industry faces significant challenges such as high costs, limited storage site availability, and the risk of long-term CO2 leakage from geological formations. The infrastructure required for transportation and injection demands substantial investment, and regulatory frameworks often lag behind technological advancements. Your efforts to reduce carbon emissions might find carbon capture utilization (CCU) more flexible, but CCS remains essential despite its limitations for irreversible CO2 containment.

Economic Impacts: Costs and ROI of CCU vs CCS

Carbon Capture Utilization (CCU) in the cement industry often incurs higher initial costs due to advanced conversion technologies but offers potential revenue streams through the sale of captured carbon products, improving overall ROI. Carbon Capture Storage (CCS) typically involves lower operational expenses related to permanent underground sequestration but faces challenges with long-term monitoring costs and regulatory compliance, impacting its economic viability. Evaluating CCU vs CCS requires analyzing capital expenditure, operational costs, potential carbon credits, and market demand for carbon-based products to determine the most cost-effective CCS strategy for cement manufacturers.

Environmental Implications in Cement Sector

Carbon Capture Utilization (CCU) in the cement sector transforms captured CO2 into valuable products like concrete additives, reducing overall emissions and promoting circular carbon economy benefits. Carbon Capture Storage (CCS), by contrast, involves long-term sequestration of CO2 underground, effectively preventing immediate atmospheric release but requiring secure geological formations and monitoring to avoid leakage risks. The environmental implications differ significantly: CCU supports material reuse and lowers carbon intensity, while CCS provides a more direct reduction of carbon emissions but with higher energy and infrastructure demands.

Future Prospects and Innovations in Cement Carbon Capture

Future prospects in cement carbon capture highlight a shift from traditional carbon capture storage (CCS) toward carbon capture utilization (CCU), enabling the conversion of CO2 into valuable byproducts such as synthetic aggregates or carbonates used in cement formulations. Innovations like mineralization-based CCU methods offer permanent carbon sequestration while improving cement strength and durability, addressing both emissions reduction and material performance. Emerging technologies integrating CCU with renewable energy sources and advanced catalysts are expected to enhance carbon capture efficiency and lower operational costs in the cement industry.

Carbon Capture Utilization vs Carbon Capture Storage (Cement Context) Infographic

libmatt.com

libmatt.com