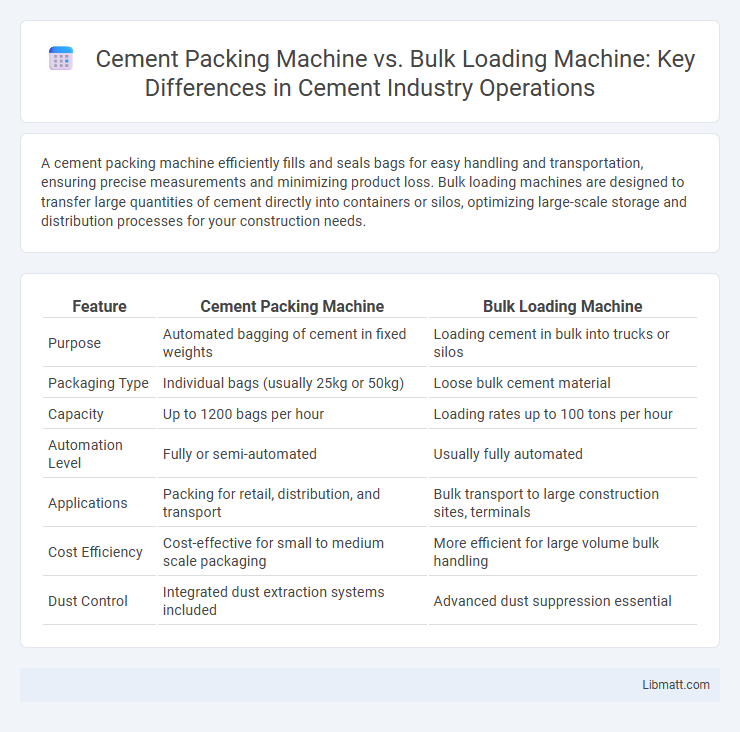

A cement packing machine efficiently fills and seals bags for easy handling and transportation, ensuring precise measurements and minimizing product loss. Bulk loading machines are designed to transfer large quantities of cement directly into containers or silos, optimizing large-scale storage and distribution processes for your construction needs.

Table of Comparison

| Feature | Cement Packing Machine | Bulk Loading Machine |

|---|---|---|

| Purpose | Automated bagging of cement in fixed weights | Loading cement in bulk into trucks or silos |

| Packaging Type | Individual bags (usually 25kg or 50kg) | Loose bulk cement material |

| Capacity | Up to 1200 bags per hour | Loading rates up to 100 tons per hour |

| Automation Level | Fully or semi-automated | Usually fully automated |

| Applications | Packing for retail, distribution, and transport | Bulk transport to large construction sites, terminals |

| Cost Efficiency | Cost-effective for small to medium scale packaging | More efficient for large volume bulk handling |

| Dust Control | Integrated dust extraction systems included | Advanced dust suppression essential |

Introduction to Cement Packing and Bulk Loading Machines

Cement packing machines are designed to precisely fill cement into bags, ensuring consistent weight and minimizing material loss during packaging, which enhances transport and storage efficiency. Bulk loading machines automate the transfer of loose cement from storage silos directly into bulk transport vehicles, optimizing large-scale distribution and reducing manual labor. Your choice between these machines depends on whether you need individual bag packaging or rapid bulk transfer for industrial-scale operations.

Key Differences Between Packing and Bulk Loading Machines

Cement packing machines are designed to fill and seal cement into bags with precise weight control, ensuring efficient handling and transportation, while bulk loading machines handle large volumes of loose cement for direct transfer into silos or transportation vehicles without individual packaging. The primary difference lies in packaging; packing machines prioritize accuracy and protection for retail distribution, whereas bulk loaders focus on speed and capacity for industrial-scale handling. Your choice depends on whether you require packaged cement for retail or bulk transfer for large construction projects.

Working Principles: How Each Machine Operates

Cement packing machines operate by automatically filling preformed bags with precise quantities of cement using volumetric or gravimetric methods, then sealing them for distribution. Bulk loading machines employ pneumatic or mechanical conveyors to transfer loose cement directly into larger containers or silos without packaging, facilitating high-volume transport. Both systems optimize efficiency, with packing machines ideal for retail packaging and bulk loaders designed for large-scale industrial handling and storage.

Capacity and Output Comparison

Cement packing machines typically handle capacities ranging from 1 to 5 tons per hour, producing neatly packed bags suitable for retail and construction site use. Bulk loading machines can manage significantly higher throughput, often exceeding 20 tons per hour, designed for efficient transfer of loose cement into silos, trucks, or larger containers. The output efficiency of packing machines is focused on precision and packaging quality, while bulk loaders prioritize rapid, large-volume handling to optimize logistics and storage processes.

Advantages of Cement Packing Machines

Cement packing machines offer precise, automated filling that reduces human error and enhances efficiency in packaging operations. These machines ensure consistent bag weight and optimize material handling, which improves productivity and minimizes product waste. Your business benefits from faster, safer packing processes and reduced labor costs when choosing cement packing machines over bulk loading alternatives.

Benefits of Bulk Loading Machines

Bulk loading machines streamline the transportation process by allowing rapid and efficient transfer of cement in bulk quantities, significantly reducing labor costs and minimizing material wastage compared to traditional cement packing machines. These machines enhance operational safety by limiting manual handling and exposure to dust, while ensuring consistent flow rates and accurate loading volumes for your bulk shipments. Investing in bulk loading equipment optimizes storage space and accelerates delivery times, offering substantial benefits for large-scale cement distributors and contractors.

Cost Analysis: Initial Investment and Operation

Cement packing machines require a higher initial investment due to their complex automation and precision components, but they offer lower operational costs by minimizing labor and reducing material waste. Bulk loading machines have a lower upfront cost but incur higher operating expenses from increased labor needs and potential spillage during loading. Your choice depends on balancing upfront capital against long-term efficiency and maintenance expenses.

Suitability for Different Cement Distribution Methods

Cement packing machines are ideal for small to medium-scale cement distribution, ensuring accurate, bagged packaging suitable for retail and transport to local markets. Bulk loading machines are designed for large-scale cement distribution, efficiently handling loose cement and loading into silos, trucks, or railcars for wholesale and industrial use. Your choice depends on the scale and method of distribution, with packing machines suited for bagged delivery and bulk loaders for direct, high-volume shipment.

Environmental Impact and Dust Control

Cement packing machines typically generate less dust during operation due to enclosed packing processes and integrated dust extraction systems, which effectively minimize airborne particulate emissions in cement plants. Bulk loading machines expose larger volumes of cement to the atmosphere, increasing the risk of dust dispersion unless equipped with advanced dust suppression technologies like pulse jet filters or water spray systems. Environmental impact assessments show that optimizing dust control in either system reduces respiratory hazards for workers and lowers particulate pollution contributing to air quality degradation.

Choosing the Right Machine for Your Cement Plant

Selecting the right equipment for your cement plant depends on production scale and packaging needs. Cement packing machines offer precise filling, consistent bagging, and are ideal for smaller or retail markets requiring individual bags. Bulk loading machines efficiently handle large volumes, streamlining transport and reducing labor for industrial-scale distribution, making them suitable for high-capacity cement plants.

Cement packing machine vs Bulk loading machine Infographic

libmatt.com

libmatt.com