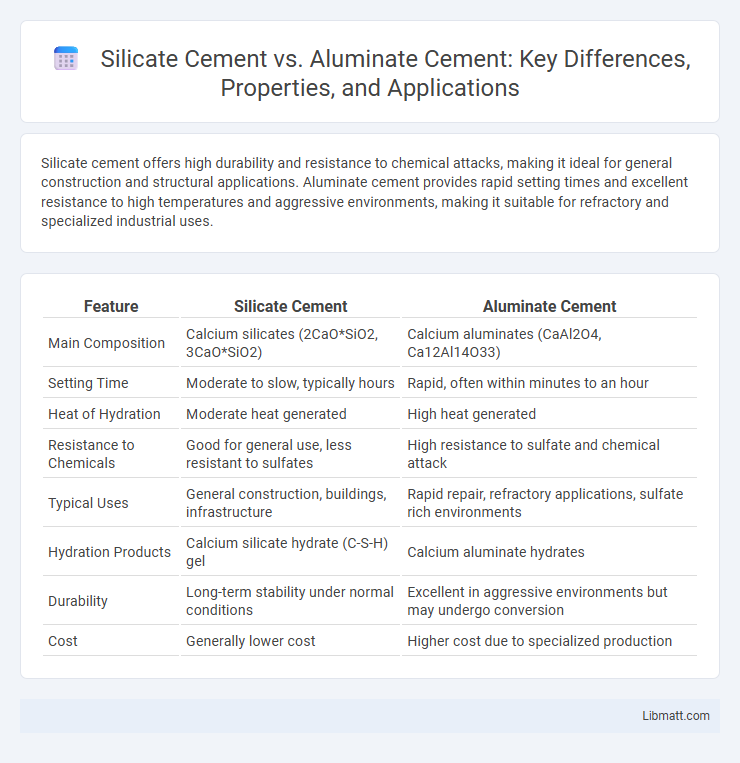

Silicate cement offers high durability and resistance to chemical attacks, making it ideal for general construction and structural applications. Aluminate cement provides rapid setting times and excellent resistance to high temperatures and aggressive environments, making it suitable for refractory and specialized industrial uses.

Table of Comparison

| Feature | Silicate Cement | Aluminate Cement |

|---|---|---|

| Main Composition | Calcium silicates (2CaO*SiO2, 3CaO*SiO2) | Calcium aluminates (CaAl2O4, Ca12Al14O33) |

| Setting Time | Moderate to slow, typically hours | Rapid, often within minutes to an hour |

| Heat of Hydration | Moderate heat generated | High heat generated |

| Resistance to Chemicals | Good for general use, less resistant to sulfates | High resistance to sulfate and chemical attack |

| Typical Uses | General construction, buildings, infrastructure | Rapid repair, refractory applications, sulfate rich environments |

| Hydration Products | Calcium silicate hydrate (C-S-H) gel | Calcium aluminate hydrates |

| Durability | Long-term stability under normal conditions | Excellent in aggressive environments but may undergo conversion |

| Cost | Generally lower cost | Higher cost due to specialized production |

Introduction to Silicate and Aluminate Cements

Silicate cement primarily consists of calcium silicates that hydrate to form a hard, durable matrix ideal for standard construction needs. Aluminate cement contains calcium aluminates which provide rapid setting and high early strength, making it suitable for specialized applications demanding quick turnaround. Your choice depends on project requirements such as setting time, strength development, and resistance to chemical attacks.

Chemical Composition Comparison

Silicate cement primarily consists of calcium silicates such as tricalcium silicate (C3S) and dicalcium silicate (C2S), which contribute to its strength development through hydration. Aluminate cement is rich in calcium aluminates, mainly monocalcium aluminate (CA) and monocalcium dialuminate (CA2), enabling rapid strength gain and resistance to chemical attack. The distinct chemical compositions influence their hydration mechanisms, setting times, and performance in various environmental conditions.

Manufacturing Processes

Silicate cement is produced by heating a mixture of limestone and clay to form clinker, which is then ground into a fine powder, whereas aluminate cement is manufactured by sintering a mixture of bauxite and limestone at high temperatures. The silicate cement process involves calcination and clinker formation, producing calcium silicates responsible for strength development; aluminate cement manufacturing emphasizes the formation of calcium aluminates, resulting in rapid setting characteristics. Precise temperature control during sintering is crucial for both types to achieve the desired mineral phases that determine their hydration behavior and performance.

Setting and Hardening Mechanisms

Silicate cement sets and hardens through the hydration of calcium silicates, producing calcium silicate hydrate (C-S-H) gel that imparts strength over time. Aluminate cement undergoes rapid hydration of calcium aluminate phases, forming calcium aluminate hydrates that lead to quicker setting and early strength development. The distinct chemical reactions in silicate and aluminate cements influence their setting times, durability, and resistance to chemical attacks.

Mechanical Strength and Durability

Silicate cement exhibits high compressive strength and excellent long-term durability, making it suitable for general construction purposes. Aluminate cement offers rapid strength development and superior resistance to chemical attacks, especially in aggressive environments like sewage and marine applications. The choice between silicate and aluminate cement depends on performance requirements, with silicate cement favored for structural integrity and aluminate cement preferred for specialized durability.

Heat and Chemical Resistance

Silicate cement offers moderate heat resistance up to 650degC and excels in structural applications due to its strong mechanical properties, but it is less effective against aggressive chemicals. Aluminate cement demonstrates superior heat resistance, maintaining stability beyond 1400degC, and shows exceptional chemical resistance especially against acidic and sulfate environments, making it ideal for refractory and chemically harsh conditions. Your choice depends on the specific requirements for thermal durability and chemical exposure in your project.

Applications in Construction

Silicate cement is widely utilized in general construction for its high compressive strength and durability, making it ideal for residential buildings, bridges, and pavements. Aluminate cement excels in refractory applications and rapid-setting environments due to its high early strength and resistance to chemical attack, often used in sewage treatment plants and heat-resistant structures. Understanding the specific performance requirements and environmental conditions helps optimize the choice between silicate and aluminate cements for construction projects.

Environmental Impact and Sustainability

Silicate cement typically has a higher carbon footprint due to the significant energy required for clinker production, contributing to greater CO2 emissions compared to aluminate cement, which has lower limestone content and demands less calcination energy. Aluminate cement offers improved sustainability by enabling faster setting times and increased chemical resistance, reducing resource consumption during construction and extending the lifespan of structures. Your choice between these cements can impact the environmental sustainability of a project, especially when considering factors like carbon emissions, durability, and resource efficiency.

Cost and Availability

Silicate cement is generally more cost-effective and widely available due to its extensive use in construction and abundant raw materials like limestone and clay. Aluminate cement, while offering superior chemical resistance and rapid setting properties, tends to be more expensive and less readily accessible because it relies on bauxite, a less common resource. Your choice between the two should consider budget constraints and the specific availability of materials in your region.

Conclusion: Choosing the Right Cement

Silicate cement offers high early strength and durability, making it ideal for general construction and structural applications. Aluminate cement provides rapid setting and excellent resistance to chemical attack, suitable for refractory and repair works. Selecting the right cement depends on project requirements such as strength, setting time, and environmental exposure.

Silicate Cement vs Aluminate Cement Infographic

libmatt.com

libmatt.com