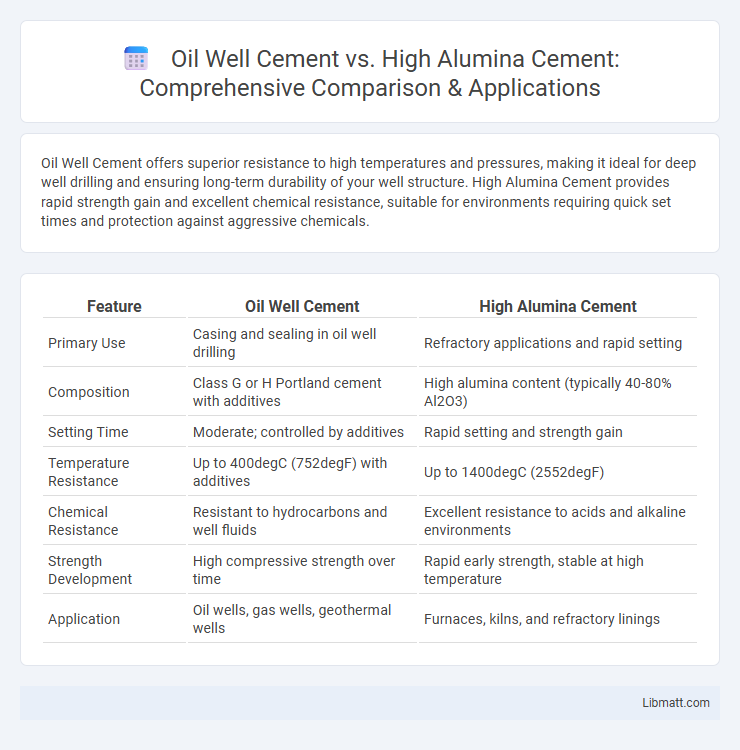

Oil Well Cement offers superior resistance to high temperatures and pressures, making it ideal for deep well drilling and ensuring long-term durability of your well structure. High Alumina Cement provides rapid strength gain and excellent chemical resistance, suitable for environments requiring quick set times and protection against aggressive chemicals.

Table of Comparison

| Feature | Oil Well Cement | High Alumina Cement |

|---|---|---|

| Primary Use | Casing and sealing in oil well drilling | Refractory applications and rapid setting |

| Composition | Class G or H Portland cement with additives | High alumina content (typically 40-80% Al2O3) |

| Setting Time | Moderate; controlled by additives | Rapid setting and strength gain |

| Temperature Resistance | Up to 400degC (752degF) with additives | Up to 1400degC (2552degF) |

| Chemical Resistance | Resistant to hydrocarbons and well fluids | Excellent resistance to acids and alkaline environments |

| Strength Development | High compressive strength over time | Rapid early strength, stable at high temperature |

| Application | Oil wells, gas wells, geothermal wells | Furnaces, kilns, and refractory linings |

Introduction to Oil Well Cement and High Alumina Cement

Oil Well Cement is a specialized type of cement designed to withstand high temperatures and pressures encountered during oil and gas well drilling and completion. High Alumina Cement, on the other hand, is known for its rapid setting time and exceptional resistance to chemical corrosion and high temperatures, making it suitable for refractory applications. Understanding the unique properties of each cement type helps you select the right material for specific industrial needs involving durability and thermal stability.

Chemical Composition Differences

Oil well cement primarily consists of Portland cement compounds such as tricalcium silicate (C3S) and dicalcium silicate (C2S), designed to withstand high temperatures and pressures for well integrity. High alumina cement contains a high percentage of calcium aluminate phases, notably monocalcium aluminate (CA) and may include gehlenite, offering rapid strength development and excellent resistance to chemical attack. The distinct chemical compositions influence their performance, with oil well cement optimized for downhole durability and high alumina cement suitable for refractory and corrosive environments.

Manufacturing Processes

Oil Well Cement is produced by grinding clinker with gypsum and other additives tailored to withstand high pressure and temperature conditions in drilling environments, using rotary kilns to achieve precise chemical compositions. High Alumina Cement is manufactured by rapidly cooling a molten mixture of bauxite and limestone in rotary kilns, resulting in a clinker with high alumina content that provides quick setting and high early strength. The distinct raw materials and cooling techniques in their manufacturing directly influence the performance characteristics suited for oil well casing integrity versus refractory and rapid repair applications.

Key Physical and Mechanical Properties

Oil well cement exhibits high compressive strength and excellent resistance to high temperatures and pressures, making it ideal for drilling operations in extreme environments. High alumina cement offers rapid setting and superior resistance to chemical attack, but typically has lower long-term strength compared to oil well cement. Your choice between these cements depends on the specific downhole conditions and the physical and mechanical demands of the drilling project.

Performance in Extreme Environments

Oil Well Cement exhibits superior resistance to high temperatures and corrosive gases, making it ideal for maintaining well integrity in extreme downhole conditions. High Alumina Cement offers rapid strength development and excellent sulfate resistance, which enhances durability in aggressive environments such as seawater exposure or acidic formations. Understanding these performance differences helps you select the appropriate cement for optimal reliability and longevity in challenging oil and gas well operations.

Application Areas and Industry Usage

Oil Well Cement is primarily used in the petroleum industry for cementing oil and gas wells, providing zonal isolation and structural support under high-pressure, high-temperature conditions. High Alumina Cement finds applications in refractory materials, chemical plants, and environments requiring rapid strength development and resistance to high temperatures and corrosion. While Oil Well Cement excels in subsurface well integrity, High Alumina Cement is favored in industrial settings demanding enhanced thermal and chemical durability.

Advantages of Oil Well Cement

Oil Well Cement offers superior durability and excellent resistance to high temperatures and pressures, making it ideal for deep and offshore well applications. Its low permeability and strong bonding capabilities ensure long-term well integrity and minimize the risk of fluid migration. Enhanced chemical resistance against sulfates and chlorides provides added protection in harsh subsurface environments.

Advantages of High Alumina Cement

High Alumina Cement offers superior resistance to high temperatures and chemical corrosion compared to Oil Well Cement, making it ideal for demanding environments like geothermal wells. Its rapid strength development reduces setting time, enhancing operational efficiency and minimizing downtime during well completion. You benefit from enhanced durability and stability in aggressive subsurface conditions, ensuring long-term integrity of well structures.

Limitations and Challenges

Oil Well Cement faces limitations such as reduced performance under extremely high temperatures and pressures, causing potential integrity failures in deep wells. High Alumina Cement exhibits challenges including rapid strength loss over time and susceptibility to conversion reactions that compromise durability in aggressive downhole environments. Both cements require careful formulation and application to overcome these restrictions in complex oil well conditions.

Selecting the Right Cement for Oil and Gas Projects

Selecting the right cement for oil and gas projects hinges on understanding the distinct properties of oil well cement and high alumina cement. Oil well cement provides excellent compressive strength and resistance to high temperatures and pressures common in deep wells, making it ideal for zonal isolation and casing support. High alumina cement excels in environments with rapid temperature changes and aggressive chemical exposure, but its application is typically limited to special circumstances requiring enhanced chemical resistance and faster setting times.

Oil Well Cement vs High Alumina Cement Infographic

libmatt.com

libmatt.com