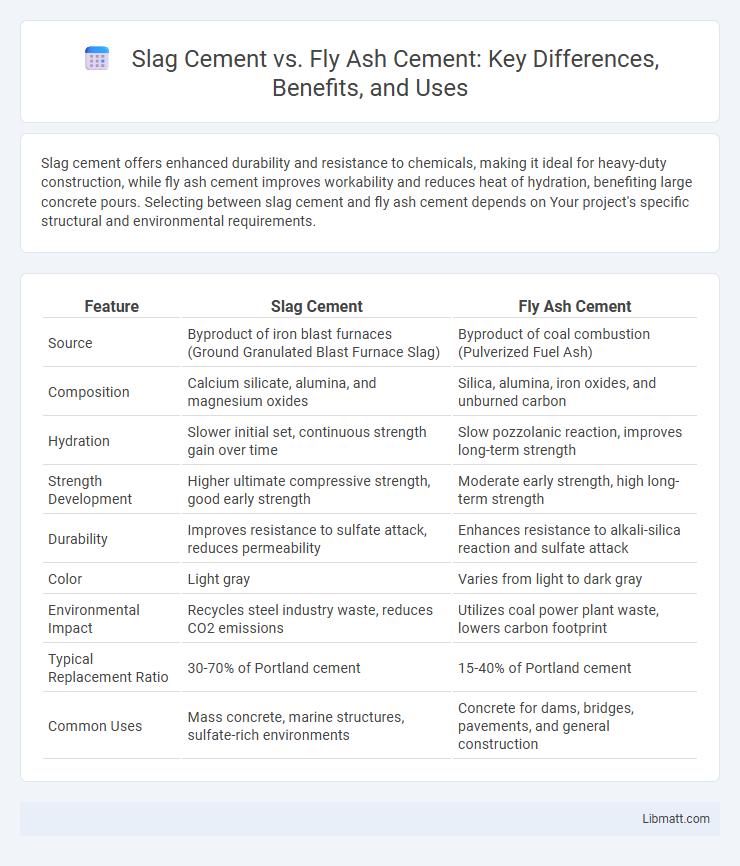

Slag cement offers enhanced durability and resistance to chemicals, making it ideal for heavy-duty construction, while fly ash cement improves workability and reduces heat of hydration, benefiting large concrete pours. Selecting between slag cement and fly ash cement depends on Your project's specific structural and environmental requirements.

Table of Comparison

| Feature | Slag Cement | Fly Ash Cement |

|---|---|---|

| Source | Byproduct of iron blast furnaces (Ground Granulated Blast Furnace Slag) | Byproduct of coal combustion (Pulverized Fuel Ash) |

| Composition | Calcium silicate, alumina, and magnesium oxides | Silica, alumina, iron oxides, and unburned carbon |

| Hydration | Slower initial set, continuous strength gain over time | Slow pozzolanic reaction, improves long-term strength |

| Strength Development | Higher ultimate compressive strength, good early strength | Moderate early strength, high long-term strength |

| Durability | Improves resistance to sulfate attack, reduces permeability | Enhances resistance to alkali-silica reaction and sulfate attack |

| Color | Light gray | Varies from light to dark gray |

| Environmental Impact | Recycles steel industry waste, reduces CO2 emissions | Utilizes coal power plant waste, lowers carbon footprint |

| Typical Replacement Ratio | 30-70% of Portland cement | 15-40% of Portland cement |

| Common Uses | Mass concrete, marine structures, sulfate-rich environments | Concrete for dams, bridges, pavements, and general construction |

Introduction to Slag Cement and Fly Ash Cement

Slag cement, also known as ground granulated blast furnace slag (GGBFS), is a byproduct of iron production that improves concrete durability and resistance to chemical attack. Fly ash cement is derived from the fine particles collected from coal combustion in power plants and enhances concrete workability and long-term strength. Both materials are widely used supplementary cementitious materials (SCMs) that contribute to sustainable construction by reducing Portland cement consumption.

Composition and Chemical Properties

Slag cement primarily consists of ground granulated blast furnace slag, a byproduct of steel production rich in calcium, silica, and alumina, which enhances durability and resistance to chemical attacks. Fly ash cement contains fine particles of coal combustion residues, predominantly silica, alumina, and iron oxide, contributing to improved workability and reduced permeability in concrete. Understanding the distinct chemical compositions of slag and fly ash cements helps you select the appropriate material to optimize performance for specific construction applications.

Manufacturing Processes

Slag cement is produced by rapidly cooling molten blast furnace slag, forming granules that are then ground into a fine powder, which enhances its cementitious properties. Fly ash cement involves capturing fine particles from coal combustion in power plants and processing them to improve reactivity before blending with Portland cement. Understanding these manufacturing processes helps you choose the optimal supplementary cementitious material for your concrete applications.

Key Differences in Performance

Slag cement enhances concrete durability and sulfate resistance due to its latent hydraulic properties, offering slower strength gain but improved long-term strength compared to fly ash cement. Fly ash cement improves workability and reduces heat of hydration while providing moderate strength development and enhanced resistance to alkali-silica reaction. Both materials contribute to sustainability by utilizing industrial by-products, but slag cement is preferred for higher early strength and chemical resistance, whereas fly ash excels in improving concrete flow and reducing permeability.

Strength Development and Durability

Slag cement exhibits slower early strength development but achieves higher long-term strength compared to fly ash cement, which provides moderate early strength gain and consistent improvement over time. Both materials enhance concrete durability by reducing permeability and improving resistance to sulfate attack, with slag cement showing superior performance in chloride ion penetration resistance. The choice between slag and fly ash cements depends on specific project requirements related to strength timeline and environmental durability conditions.

Environmental Impact and Sustainability

Slag cement and fly ash cement both contribute to environmental sustainability by recycling industrial by-products, reducing landfill waste, and lowering carbon emissions compared to traditional Portland cement. Slag cement is derived from granulated blast furnace slag, a by-product of steel manufacturing, offering significant reductions in CO2 emissions and improved durability in concrete applications. Fly ash, a residue from coal combustion in power plants, enhances concrete performance and extends material longevity while minimizing environmental impact through waste reuse and decreased reliance on raw materials.

Applications in Construction

Slag cement is widely used in mass concrete structures, such as dams and bridges, due to its excellent durability and resistance to sulfate attack. Fly ash cement enhances workability and reduces water demand, making it ideal for high-performance concrete in pavements and high-rise buildings. Both materials improve sustainability by recycling industrial byproducts and reducing Portland cement consumption in construction projects.

Compatibility with Other Materials

Slag cement offers excellent compatibility with various aggregates and admixtures, enhancing concrete durability and strength when combined with Portland cement. Fly ash cement improves workability and reduces permeability but may require careful adjustment of admixtures to avoid retardation in setting time. Understanding the compatibility of your chosen cement type with specific materials ensures optimal performance and long-term stability in construction projects.

Cost Comparison and Availability

Slag cement typically costs more than fly ash cement due to its energy-intensive manufacturing process and limited production facilities. Fly ash is often more affordable and widely available as a byproduct of coal combustion in power plants, making it easier to source for large-scale projects. Evaluating your project's budget and regional supply can help you decide the most cost-effective and accessible option.

Choosing the Right Supplementary Cementitious Material

Selecting the appropriate supplementary cementitious material (SCM) like slag cement or fly ash depends on factors such as concrete durability, strength requirements, and environmental conditions. Slag cement, derived from granulated blast furnace slag, enhances resistance to sulfate attack and improves long-term strength, making it ideal for harsh environments. Fly ash, a byproduct of coal combustion, improves workability, reduces heat of hydration, and contributes to sustainability by recycling industrial waste, often favored in mass concrete applications and structures requiring high durability.

Slag Cement vs Fly Ash Cement Infographic

libmatt.com

libmatt.com