Bypass dust is a fine particulate collected from the exhaust gases of cement kilns, containing higher levels of volatile compounds and alkalis, while cement kiln dust (CKD) consists of raw materials and partially calcined fragments removed during the kiln process. Understanding the differences between bypass dust and CKD is crucial for managing your cement production waste and optimizing environmental compliance.

Table of Comparison

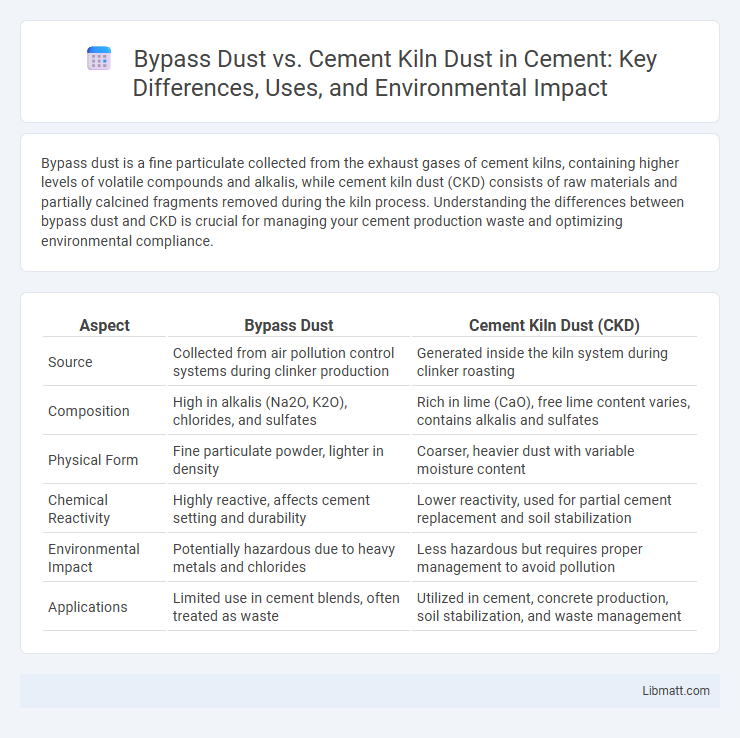

| Aspect | Bypass Dust | Cement Kiln Dust (CKD) |

|---|---|---|

| Source | Collected from air pollution control systems during clinker production | Generated inside the kiln system during clinker roasting |

| Composition | High in alkalis (Na2O, K2O), chlorides, and sulfates | Rich in lime (CaO), free lime content varies, contains alkalis and sulfates |

| Physical Form | Fine particulate powder, lighter in density | Coarser, heavier dust with variable moisture content |

| Chemical Reactivity | Highly reactive, affects cement setting and durability | Lower reactivity, used for partial cement replacement and soil stabilization |

| Environmental Impact | Potentially hazardous due to heavy metals and chlorides | Less hazardous but requires proper management to avoid pollution |

| Applications | Limited use in cement blends, often treated as waste | Utilized in cement, concrete production, soil stabilization, and waste management |

Introduction to Bypass Dust and Cement Kiln Dust

Bypass dust and cement kiln dust (CKD) are byproducts generated during cement manufacturing, each with distinct compositions and environmental impacts. Bypass dust is a fine particulate collected from the exhaust gases, rich in alkali chlorides and sulfates, while CKD is a powdery material obtained from the kiln's raw meal and clinker dust, containing calcium oxide and unburned carbon. Understanding the differences between these dusts is crucial for effective waste management and potential resource recovery in cement production.

Chemical Composition Differences

Bypass dust and cement kiln dust differ significantly in their chemical compositions, impacting their reuse and environmental handling. Bypass dust typically contains higher concentrations of alkali metals, such as potassium and sodium, along with elevated levels of chlorides and sulfates due to its origin from cement kiln stack gases. Cement kiln dust generally exhibits a more balanced chemical profile with greater amounts of calcium oxide (CaO) and lower levels of volatile alkali compounds, reflecting its derivation from raw materials and partially calcined feed.

Generation Processes in Cement Production

Bypass dust and cement kiln dust are byproducts generated during cement production, originating from different stages of the process. Bypass dust is collected from exhaust gases in the kiln's preheater system, containing fine particles of raw materials and volatile compounds, while cement kiln dust accumulates directly from the kiln's combustion zone, comprising partially calcined raw material and clinker dust. Understanding these generation processes helps in managing your plant's emissions and optimizing material recycling efforts.

Physical Properties Comparison

Bypass dust and cement kiln dust differ significantly in their physical properties, with bypass dust typically having finer particle sizes and higher volatility due to its capture from the kiln system's exhaust gases. Cement kiln dust is coarser, denser, and contains a larger proportion of unreacted raw material, affecting its reactivity and handling characteristics. Understanding these differences helps optimize your use of these materials in concrete production or waste management applications.

Environmental Impact Assessment

Bypass dust and cement kiln dust (CKD) both pose significant environmental challenges due to their alkaline nature and heavy metal content, contributing to air, soil, and water contamination if improperly managed. Environmental impact assessments reveal that bypass dust generally contains higher levels of hazardous compounds like volatile organic compounds and heavy metals, making its disposal and reuse more critical for minimizing ecological damage. Effective containment, stabilization, and recycling strategies are essential to reducing the environmental footprint of both byproducts in cement manufacturing processes.

Utilization and Recycling Opportunities

Bypass dust, generated from cement kiln exhaust gases, contains high levels of alkalis and chlorides, making it suitable for use in limited quantities as a raw material substitute in cement production or as an additive in blended cements. Cement kiln dust (CKD) is a byproduct collected from kiln and preheater cyclones with alkaline properties that enable its effective reuse in soil stabilization, waste solidification, and as a partial cement clinker replacement. Both bypass dust and CKD offer recycling opportunities that reduce landfill disposal, lower natural resource consumption, and improve sustainability within the cement manufacturing industry.

Regulatory Guidelines and Standards

Bypass dust and cement kiln dust are regulated under specific environmental guidelines due to their potential hazardous content, including heavy metals and alkaline components. Regulatory standards such as the Resource Conservation and Recovery Act (RCRA) classify these industrial byproducts based on toxicity characteristics, necessitating proper handling, storage, and disposal to prevent soil and water contamination. Understanding these standards is crucial for compliance and environmental protection when managing your bypass dust or cement kiln dust waste streams.

Handling, Storage, and Transportation

Bypass dust and cement kiln dust require careful handling due to their fine particle size and potential health hazards, with personal protective equipment essential to minimize inhalation risks. Storage must be in sealed, weather-resistant containers to prevent moisture absorption and airborne dispersion, ensuring environmental compliance. Transportation demands secure packaging and adherence to regulations on hazardous materials to protect workers and prevent contamination during transit.

Effects on Cement Quality and Performance

Bypass Dust and Cement Kiln Dust differ significantly in their chemical composition, influencing cement quality and performance. Bypass Dust, rich in alkalis and chlorides, can lead to efflorescence and decreased durability when incorporated into cement, whereas Cement Kiln Dust contains higher calcium content that may enhance early strength but risk increased porosity. Cement manufacturers must carefully balance these dusts to optimize strength development, workability, and long-term durability of the final product.

Future Trends in Dust Management

Bypass dust and cement kiln dust management are evolving with innovative technologies emphasizing resource recovery and environmental compliance. Advances in carbon capture, alkaline stabilization, and recycling methods will reduce landfill dependency and mitigate air pollution. Your cement production processes can benefit from sustainable dust management practices that align with stricter emission regulations and circular economy principles.

Bypass Dust vs Cement Kiln Dust Infographic

libmatt.com

libmatt.com