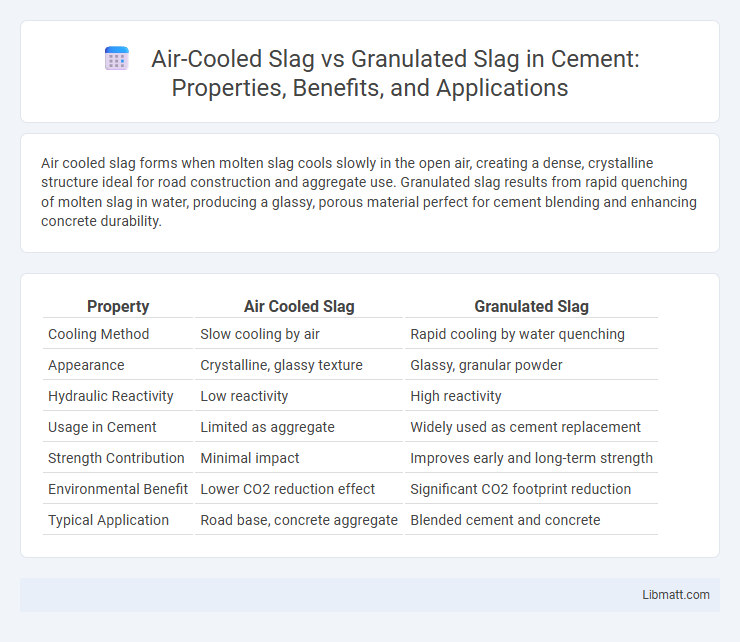

Air cooled slag forms when molten slag cools slowly in the open air, creating a dense, crystalline structure ideal for road construction and aggregate use. Granulated slag results from rapid quenching of molten slag in water, producing a glassy, porous material perfect for cement blending and enhancing concrete durability.

Table of Comparison

| Property | Air Cooled Slag | Granulated Slag |

|---|---|---|

| Cooling Method | Slow cooling by air | Rapid cooling by water quenching |

| Appearance | Crystalline, glassy texture | Glassy, granular powder |

| Hydraulic Reactivity | Low reactivity | High reactivity |

| Usage in Cement | Limited as aggregate | Widely used as cement replacement |

| Strength Contribution | Minimal impact | Improves early and long-term strength |

| Environmental Benefit | Lower CO2 reduction effect | Significant CO2 footprint reduction |

| Typical Application | Road base, concrete aggregate | Blended cement and concrete |

Introduction to Slag: Air Cooled vs Granulated

Air cooled slag and granulated slag are byproducts of the steelmaking process, differing primarily in cooling methods and physical properties. Air cooled slag solidifies slowly through exposure to ambient air, resulting in a dense, crystalline structure ideal for aggregate applications in construction. Granulated slag undergoes rapid quenching with water, producing a glassy, fine-textured material commonly utilized as a cementitious component in blended cements, enhancing durability and strength.

Formation Processes of Air Cooled and Granulated Slag

Air-cooled slag forms when molten slag is allowed to cool slowly in the open air, resulting in a solid, crystalline structure with larger particles and lower surface area. Granulated slag is produced by rapidly quenching molten slag with high-pressure water jets, causing it to solidify into a glassy, amorphous texture with fine granules suitable for cement applications. Understanding these formation processes helps you select the appropriate slag type for specific industrial uses, optimizing performance in construction materials.

Physical Properties Comparison

Air cooled slag exhibits a coarse, crystalline texture with higher density and lower surface area, resulting in slower cement hydration and strength gain. Granulated slag, cooled rapidly by water quenching, forms a glassy, amorphous structure with finer particles, higher surface area, and enhanced reactivity, promoting faster strength development in concrete. Understanding these physical properties helps you select the optimal slag type for improved durability and performance in construction applications.

Chemical Composition Differences

Air cooled slag typically contains higher levels of calcium oxide (CaO) and magnesium oxide (MgO), resulting in a denser and coarser texture due to slower cooling rates. Granulated slag is rapidly cooled in water, yielding a predominantly amorphous structure with higher silica (SiO2) and alumina (Al2O3) content, which enhances its hydraulic properties. These chemical composition differences affect their suitability for applications such as cement production, with granulated slag favored for its reactive properties and air cooled slag used mainly as aggregate.

Environmental Impact Assessment

Air cooled slag generates coarse, crystalline particles that are less reactive and limit its use in cement production, resulting in reduced opportunities for carbon footprint reduction compared to granulated slag. Granulated slag is rapidly quenched to produce a glassy, amorphous material with higher reactivity, enabling greater clinker replacement and significant CO2 emissions savings in cement manufacturing. Life cycle assessments reveal that granulated slag achieves lower embodied carbon and energy consumption due to its enhanced cementitious properties and increased potential for waste valorization in construction applications.

Applications in Construction and Industry

Air-cooled slag is commonly used in road construction, concrete aggregate, and cement production due to its angular texture and high strength properties. Granulated slag, formed by rapid cooling of molten slag, is primarily utilized as a cementitious material in blended cements, enhancing durability and reducing cost in concrete manufacturing. Both types of slag improve sustainability in construction by recycling industrial by-products and reducing the demand for natural resources.

Advantages and Disadvantages of Air Cooled Slag

Air cooled slag offers the advantage of high density and strength, making it suitable for use in construction aggregates and road bases due to its angular shape and durability. However, it has lower hydraulic reactivity compared to granulated slag, limiting its use in cementitious applications where rapid strength gain is required. The slower cooling process results in a crystalline structure which enhances stability but reduces its potential for use as a supplementary cementitious material.

Advantages and Disadvantages of Granulated Slag

Granulated slag offers superior cementitious properties compared to air cooled slag, providing higher strength and improved durability for concrete applications due to its rapid cooling process that creates a glassy, reactive surface. Its advantages include enhanced workability, better resistance to chemical attack, and reduced heat of hydration, making it ideal for mass concrete structures. However, granulated slag requires energy-intensive quenching and rapid cooling, increasing production costs, and may have variability in quality depending on cooling conditions.

Performance in Cement and Concrete Production

Air-cooled slag exhibits lower reactivity and slower strength development compared to granulated slag due to its crystalline structure, making it less effective in enhancing cement and concrete properties. Granulated slag, produced by rapid quenching, creates a glassy, amorphous material that significantly improves concrete durability, workability, and long-term strength performance. The optimized pozzolanic reactivity of granulated slag contributes to reduced hydration heat and enhanced sulfate resistance in cementitious applications.

Cost and Availability Analysis

Air cooled slag generally costs less due to its simpler production process, making it more widely available in regions with integrated steel mills. Granulated slag, produced by rapidly cooling molten slag with water, involves higher processing costs but offers superior cementitious properties, which can justify the price in specialized construction projects. Your choice between air cooled and granulated slag should consider both budget constraints and the specific material performance requirements of your application.

Air cooled slag vs Granulated slag Infographic

libmatt.com

libmatt.com