Hardburnt lime has undergone high-temperature calcination, resulting in a dense, less reactive product ideal for refractory applications and soil stabilization, whereas softburnt lime is produced at lower temperatures, yielding a more porous and reactive material suited for agricultural uses and water treatment. Your choice between the two depends on the required reactivity and application environment, balancing durability against chemical activity.

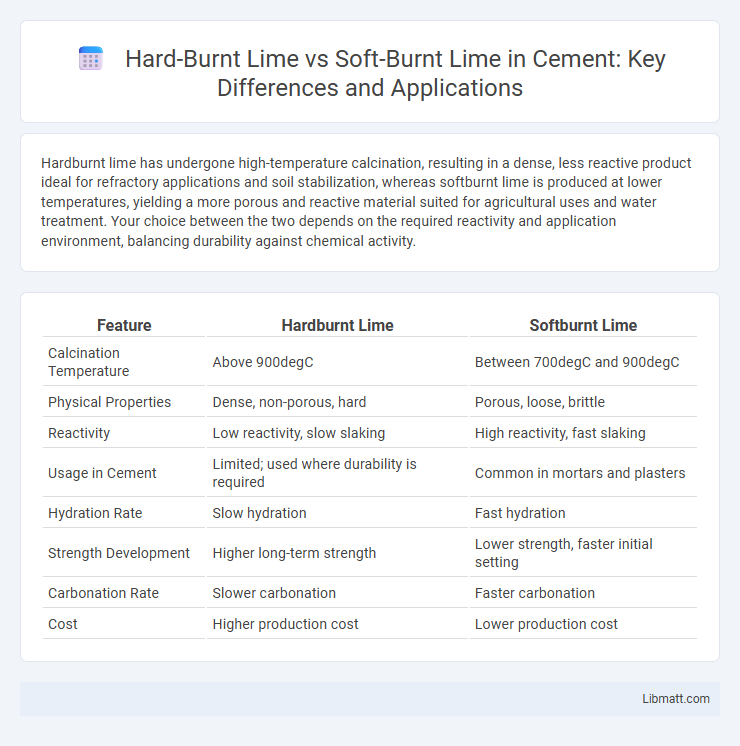

Table of Comparison

| Feature | Hardburnt Lime | Softburnt Lime |

|---|---|---|

| Calcination Temperature | Above 900degC | Between 700degC and 900degC |

| Physical Properties | Dense, non-porous, hard | Porous, loose, brittle |

| Reactivity | Low reactivity, slow slaking | High reactivity, fast slaking |

| Usage in Cement | Limited; used where durability is required | Common in mortars and plasters |

| Hydration Rate | Slow hydration | Fast hydration |

| Strength Development | Higher long-term strength | Lower strength, faster initial setting |

| Carbonation Rate | Slower carbonation | Faster carbonation |

| Cost | Higher production cost | Lower production cost |

Introduction to Hardburnt Lime and Softburnt Lime

Hardburnt lime, also known as calcium oxide, is produced by calcining limestone at high temperatures, resulting in a dense, highly reactive material primarily used in steel manufacturing and refractory applications. Softburnt lime, on the other hand, undergoes a lower temperature calcination process, yielding a more porous and less reactive form ideal for agricultural uses and environmental treatments. Both types differ significantly in chemical reactivity and physical structure, impacting their suitability for various industrial and environmental applications.

Chemical Composition Differences

Hardburnt lime is predominantly composed of calcium oxide (CaO) with minimal impurities, resulting from its high-temperature calcination process, which drives off carbon dioxide and other volatile compounds. Softburnt lime contains a higher proportion of calcium hydroxide (Ca(OH)2) and may retain uncalcined calcium carbonate (CaCO3), reflecting its lower calcination temperature and less intensive treatment. Understanding these chemical composition differences helps you select the optimal lime for applications requiring specific reactivity and solubility profiles.

Production Processes and Temperatures

Hardburnt lime is produced by calcining high-purity limestone at temperatures typically exceeding 1000degC, resulting in a dense, less reactive product ideal for industrial applications requiring slow hydration. Softburnt lime undergoes calcination at lower temperatures, around 900-1000degC, which leads to a more porous, reactive material suited for agricultural and environmental uses. Understanding these distinct production processes and temperature ranges can help you select the appropriate lime type for your specific project needs.

Physical Properties and Appearance

Hardburnt lime features a denser, more compact structure with a grayish, coarse appearance, making it suitable for high-strength applications. Softburnt lime exhibits a lighter, more porous texture with a whitish color, enhancing its reactivity and ease of hydration. Your choice between hardburnt and softburnt lime depends on the required physical properties for durability or quick reactivity in construction or industrial use.

Reactivity and Hydration Behavior

Hardburnt lime exhibits lower reactivity and slower hydration due to its dense crystalline structure, making it suitable for applications requiring gradual strength development. Softburnt lime, characterized by a more porous microstructure, demonstrates higher reactivity and faster hydration rates, ideal for processes demanding quick setting and higher initial strength. The differences in reactivity and hydration behavior directly influence their performance in construction, environmental treatment, and chemical industries.

Construction and Industrial Applications

Hardburnt lime, produced by calcining high-calcium limestone at higher temperatures, exhibits greater density and lower reactivity, making it ideal for refractory linings and steel manufacturing due to its resistance to heat and chemical wear. Softburnt lime, characterized by partial calcination and higher porosity, is preferred in soil stabilization, water treatment, and flue gas desulfurization, where faster hydration and chemical reactivity enhance performance. Both types serve critical roles in construction and industry, with hardburnt lime offering durability under extreme conditions and softburnt lime providing rapid chemical responses for environmental and structural applications.

Advantages and Limitations of Hardburnt Lime

Hardburnt lime offers higher calcium oxide content, improving its reactivity and strength in industrial applications such as steelmaking and chemical manufacturing. Its dense structure provides superior durability and resistance to hydration, enabling longer storage without significant degradation. However, hardburnt lime's reduced surface area limits its immediate solubility and softness, which can be a disadvantage in processes requiring rapid chemical reactions or soil conditioning compared to softburnt lime.

Advantages and Limitations of Softburnt Lime

Softburnt lime offers rapid reactivity and higher lime availability, making it ideal for soil stabilization and quick-setting applications. Your projects benefit from its easier crushing and better hydration properties compared to hardburnt lime, which enhances workability and reduces energy costs. However, softburnt lime may have lower mechanical strength and durability, limiting its use in structural roles where long-term stability is critical.

Environmental Impact and Sustainability

Hardburnt lime, produced at higher kiln temperatures, tends to have a more intensive carbon footprint due to greater energy consumption compared to softburnt lime, which is manufactured at lower temperatures and consumes less fuel. Softburnt lime generally results in lower CO2 emissions and is considered more sustainable for applications where its properties suffice. You can reduce environmental impact by selecting softburnt lime in construction or agricultural projects demanding sustainable, energy-efficient materials.

Choosing the Right Lime: Key Considerations

Hardburnt lime, produced at higher temperatures, offers greater reactivity and strength for industrial uses, while softburnt lime, fired at lower temperatures, provides improved workability and slower setting times ideal for agricultural applications. Selecting the right lime depends on the desired chemical composition, reactivity rate, and application environment, ensuring optimal performance in soil stabilization, construction, or environmental treatment. Assessing factors like calcium oxide content, impurity levels, and particle size distribution helps tailor lime choice to specific project requirements.

Hardburnt Lime vs Softburnt Lime Infographic

libmatt.com

libmatt.com