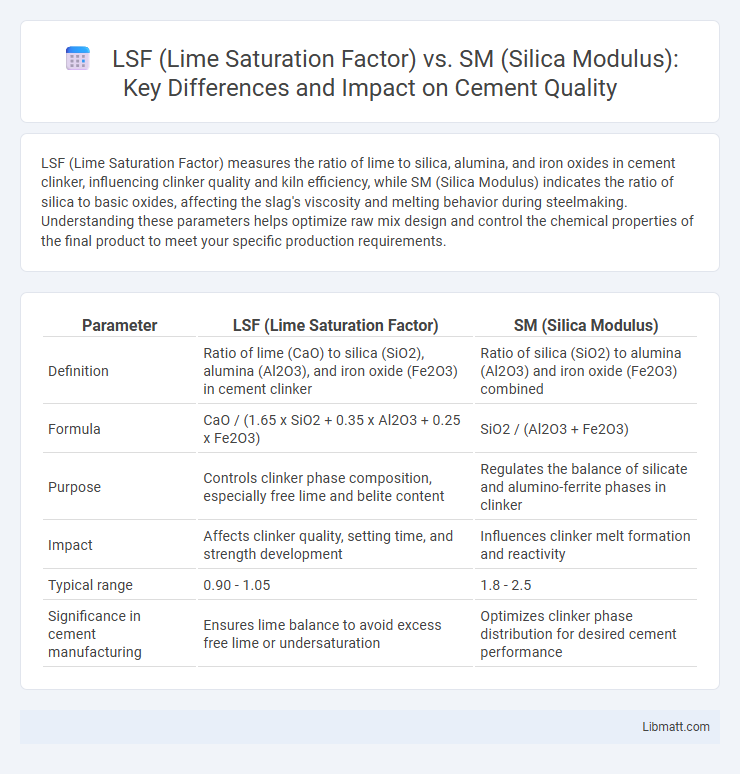

LSF (Lime Saturation Factor) measures the ratio of lime to silica, alumina, and iron oxides in cement clinker, influencing clinker quality and kiln efficiency, while SM (Silica Modulus) indicates the ratio of silica to basic oxides, affecting the slag's viscosity and melting behavior during steelmaking. Understanding these parameters helps optimize raw mix design and control the chemical properties of the final product to meet your specific production requirements.

Table of Comparison

| Parameter | LSF (Lime Saturation Factor) | SM (Silica Modulus) |

|---|---|---|

| Definition | Ratio of lime (CaO) to silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3) in cement clinker | Ratio of silica (SiO2) to alumina (Al2O3) and iron oxide (Fe2O3) combined |

| Formula | CaO / (1.65 x SiO2 + 0.35 x Al2O3 + 0.25 x Fe2O3) | SiO2 / (Al2O3 + Fe2O3) |

| Purpose | Controls clinker phase composition, especially free lime and belite content | Regulates the balance of silicate and alumino-ferrite phases in clinker |

| Impact | Affects clinker quality, setting time, and strength development | Influences clinker melt formation and reactivity |

| Typical range | 0.90 - 1.05 | 1.8 - 2.5 |

| Significance in cement manufacturing | Ensures lime balance to avoid excess free lime or undersaturation | Optimizes clinker phase distribution for desired cement performance |

Understanding LSF (Lime Saturation Factor): Definition and Significance

Lime Saturation Factor (LSF) measures the ratio of lime (CaO) to the combined amounts of silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3) in raw mix materials, playing a crucial role in cement clinker quality control. A higher LSF indicates sufficient lime for clinker formation, affecting the formation of key clinker phases such as alite, which influences cement strength and durability. Precise control of LSF ensures optimal clinker chemistry, balancing reactivity and grindability for enhanced cement performance.

What is Silica Modulus (SM) and Why Is It Important?

Silica Modulus (SM) is the ratio of silicon dioxide (SiO2) to alkalis (Na2O + K2O) in slag or cement, serving as a crucial indicator of the slag's chemical composition. This ratio influences slag properties such as viscosity, melting point, and reactivity, directly impacting clinker formation and final cement quality. Understanding SM helps optimize your cement production process by balancing slag stability and reactivity for desired strength and durability.

The Chemistry Behind LSF and SM in Cement Production

LSF (Lime Saturation Factor) and SM (Silica Modulus) are critical parameters controlling the chemical composition and phase formation in cement clinker. LSF indicates the ratio of lime (CaO) to acidic oxides like silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3), determining the availability of free lime essential for clinker stability. SM represents the ratio of silica to bases and influences the formation of silicate phases such as belite and alite, directly affecting the hydraulic properties and strength development of your cement.

Calculating LSF: Formula and Practical Examples

The Lime Saturation Factor (LSF) is calculated using the formula LSF = (CaO) / (2.8SiO2 + 1.2Al2O3), where CaO, SiO2, and Al2O3 represent the weight percentages of calcium oxide, silica, and alumina in the raw mix. Accurate calculation of LSF is crucial for cement manufacturing to ensure optimal clinker quality and prevent defects. Your practical approach might involve analyzing raw material compositions and adjusting these components to maintain LSF within the ideal range of 0.92 to 1.05.

Determining SM: Calculation Methods for Optimal Results

Determining Silica Modulus (SM) involves calculating the ratio of silicon dioxide (SiO2) to the combined amounts of calcium oxide (CaO) and magnesium oxide (MgO) in cement kiln slag or raw materials. Precise calculation methods require chemical analysis and accurate interpretation of compositional data to optimize kiln operation and clinker quality. Your ability to maintain a balanced SM ensures enhanced slag formation and improved cement durability during production.

LSF vs SM: Key Differences and Their Impact on Clinker Quality

LSF (Lime Saturation Factor) measures the ratio of available lime to the silica, alumina, and iron oxides in clinker raw mix, indicating the lime saturation crucial for forming desired clinker minerals like alite and belite, while SM (Silica Modulus) represents the ratio of silica to alumina and iron oxides, influencing the balance between silicate and aluminate phases. A higher LSF promotes clinker hardness and strength by ensuring sufficient free lime, whereas an optimal SM controls the slagging tendency and clinker melt formation, directly affecting clinker reactivity and grindability. Precise control of LSF and SM ensures enhanced clinker quality, optimizing cement performance, durability, and energy efficiency during production.

Effects of LSF Variations on Cement Properties

Variations in Lime Saturation Factor (LSF) significantly influence the strength and durability of cement by controlling the balance between belite (C2S) and alite (C3S) phases, with higher LSF values generally increasing the proportion of alite, thereby improving early strength. An optimal LSF range of 0.9 to 1.05 ensures adequate lime content to react with silica and alumina, minimizing free lime that could lead to unsoundness and compromising cement stability. Adjusting LSF affects clinker mineralogy and, consequently, Your cement's hydration rate, setting time, and resistance to chemical attacks, making precise control essential for achieving desired performance characteristics.

Influence of SM Levels on Clinker and Cement Performance

Silica Modulus (SM) significantly impacts clinker mineralogy and cement properties by controlling the ratio of silica to alkalis, thereby influencing the formation of silicate phases important for strength development. Variations in SM levels can alter the hydraulic reactivity and durability of cement, with higher SM generally promoting enhanced early strength and improved sulfate resistance. Your choice of SM during kiln feed formulation directly affects clinker quality and the performance characteristics of the final cement product.

Balancing LSF and SM: Best Practices in Cement Manufacturing

Balancing Lime Saturation Factor (LSF) and Silica Modulus (SM) is critical in cement manufacturing to optimize clinker quality and energy efficiency. Maintaining LSF between 0.90 and 1.05 ensures adequate lime content for proper mineral formation, while an SM range of 2.0 to 2.5 stabilizes silicate phases enhancing hydraulic properties. Precise control of raw material proportions through advanced kiln feeding systems and continuous chemical analysis enables manufacturers to achieve consistent clinker composition and improve overall cement performance.

Advanced Quality Control: Monitoring LSF and SM in Real-Time

Advanced quality control in cement manufacturing relies on real-time monitoring of Lime Saturation Factor (LSF) and Silica Modulus (SM) to maintain optimal clinker composition and ensure consistent product performance. Precise measurement of LSF helps regulate the lime balance, preventing excess free lime or unreacted silica, while continuous tracking of SM ensures the correct silica-alumina ratio for clinker stability. Implementing automated sensors and process control systems for LSF and SM analysis enhances operational efficiency, reduces energy consumption, and improves overall cement quality.

LSF (Lime Saturation Factor) vs SM (Silica Modulus) Infographic

libmatt.com

libmatt.com