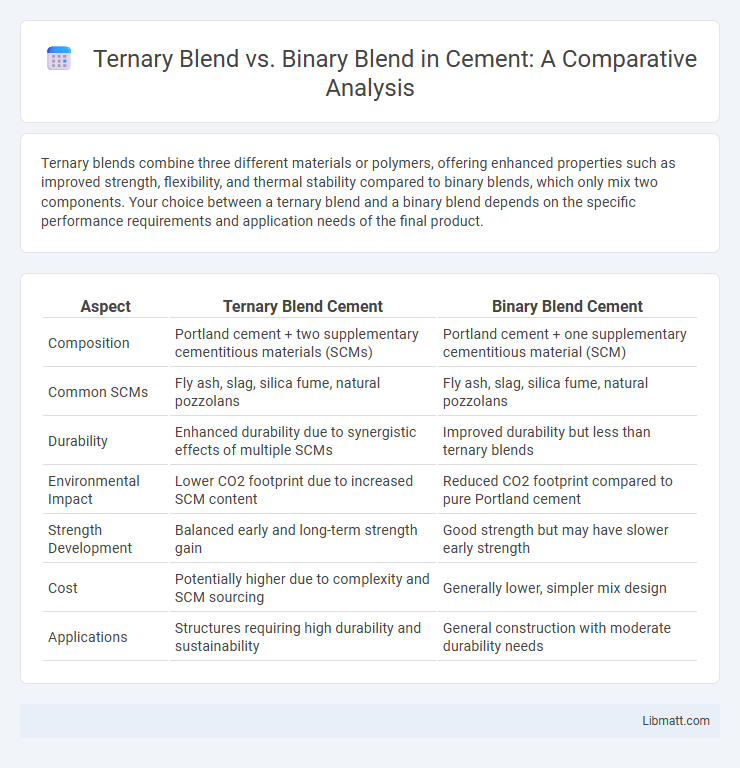

Ternary blends combine three different materials or polymers, offering enhanced properties such as improved strength, flexibility, and thermal stability compared to binary blends, which only mix two components. Your choice between a ternary blend and a binary blend depends on the specific performance requirements and application needs of the final product.

Table of Comparison

| Aspect | Ternary Blend Cement | Binary Blend Cement |

|---|---|---|

| Composition | Portland cement + two supplementary cementitious materials (SCMs) | Portland cement + one supplementary cementitious material (SCM) |

| Common SCMs | Fly ash, slag, silica fume, natural pozzolans | Fly ash, slag, silica fume, natural pozzolans |

| Durability | Enhanced durability due to synergistic effects of multiple SCMs | Improved durability but less than ternary blends |

| Environmental Impact | Lower CO2 footprint due to increased SCM content | Reduced CO2 footprint compared to pure Portland cement |

| Strength Development | Balanced early and long-term strength gain | Good strength but may have slower early strength |

| Cost | Potentially higher due to complexity and SCM sourcing | Generally lower, simpler mix design |

| Applications | Structures requiring high durability and sustainability | General construction with moderate durability needs |

Introduction to Polymer Blends

Ternary blends in polymers involve combining three different polymer components, offering enhanced material properties through the synergistic interaction of multiple phases compared to binary blends that only mix two polymers. These complex blends allow for tailored mechanical strength, thermal stability, and chemical resistance to meet specific application requirements. Understanding the differences between ternary and binary polymer blends helps optimize Your material formulations for improved performance and cost-efficiency.

Defining Binary and Ternary Blends

Binary blends consist of two different materials combined to enhance properties such as strength, flexibility, or cost-effectiveness, commonly found in polymers, alloys, or fuel mixtures. Ternary blends incorporate three distinct components, offering more complex property tuning and improved performance in applications like advanced composites or multi-fuel systems. Understanding these definitions helps you select the optimal blending strategy for your specific material or product requirements.

Key Differences Between Binary and Ternary Blends

Binary blends consist of two components combined to enhance material properties or performance, while ternary blends integrate three distinct substances, offering more complex interactions and tailored functionalities. The key differences lie in the composition complexity, compatibility challenges, and the potential to achieve customized characteristics such as improved mechanical strength, thermal stability, or chemical resistance. Your selection between binary and ternary blends depends on the specific application requirements and desired material behavior.

Material Properties Comparison

Ternary blends, composed of three distinct polymers, exhibit enhanced material properties such as improved mechanical strength, thermal stability, and chemical resistance compared to binary blends, which combine only two polymers. The synergistic interactions in ternary blends allow for tailored flexibility, impact resistance, and compatibility that binary blends often lack. These advanced properties make ternary blends more suitable for high-performance applications in automotive, aerospace, and packaging industries.

Processing Techniques for Binary vs Ternary Blends

Processing techniques for binary blends typically involve straightforward mixing of two polymers using conventional methods like extrusion or injection molding, resulting in simpler phase interactions and easier process control. Ternary blends require more advanced processing strategies to manage the compatibility and dispersion of three distinct components, often necessitating specialized compatibilizers, multi-step extrusion, or reactive blending to achieve optimal performance and morphology. Your choice between binary and ternary blends should consider the complexity of processing equipment and the desired material properties for the application.

Performance and Application Areas

Ternary blends, incorporating three different polymers, typically offer enhanced mechanical properties and thermal stability compared to binary blends, making them suitable for advanced automotive and aerospace applications. Binary blends, combining two polymers, often provide balanced cost-effectiveness and improved impact resistance, commonly used in packaging and consumer goods. The choice between ternary and binary blends depends on specific performance requirements such as tensile strength, durability, and environmental resistance in target applications.

Challenges in Blending Multiple Polymers

Blending multiple polymers, such as in ternary blends compared to binary blends, presents challenges in achieving uniform dispersion and compatibility among all components, which can affect the mechanical properties and thermal stability of the final material. You must carefully control processing parameters and select appropriate compatibilizers to address phase separation and interfacial tension issues. Optimizing these factors ensures enhanced performance and durability in complex polymer blends used in advanced applications.

Morphology and Compatibility Issues

Ternary blends, consisting of three polymer components, exhibit more complex morphology compared to binary blends due to the increased interactions and phase separation patterns. Compatibility issues arise as achieving a uniform dispersion and stable interface among all three polymers is more challenging, often requiring compatibilizers to improve interfacial adhesion and enhance mechanical properties. Understanding these morphological characteristics is crucial for optimizing Your blend's performance and ensuring desired material properties in applications.

Recent Advances in Ternary Blend Technologies

Recent advances in ternary blend technologies have demonstrated significant improvements in photovoltaic efficiency and stability compared to binary blends by incorporating a third component such as polymer, fullerene, or non-fullerene acceptors to optimize light absorption and charge transport. Enhanced morphological control in ternary blends enables better phase separation and reduced recombination losses, resulting in power conversion efficiencies surpassing 18% in organic solar cells. These innovations also facilitate tunable energy levels and complementarity in absorption spectra, making ternary blends a promising candidate for next-generation high-performance optoelectronic devices.

Future Trends and Research Directions

Research on ternary blend photovoltaic cells is rapidly advancing, revealing enhanced efficiency and stability compared to traditional binary blends due to improved morphological control and charge transport. Emerging trends emphasize the integration of non-fullerene acceptors and novel donor polymers to optimize energy level alignment and light absorption in ternary systems. Future studies focus on scalable fabrication techniques and detailed mechanistic understanding to accelerate commercial viability and performance improvements in next-generation organic solar cells.

Ternary blend vs Binary blend Infographic

libmatt.com

libmatt.com