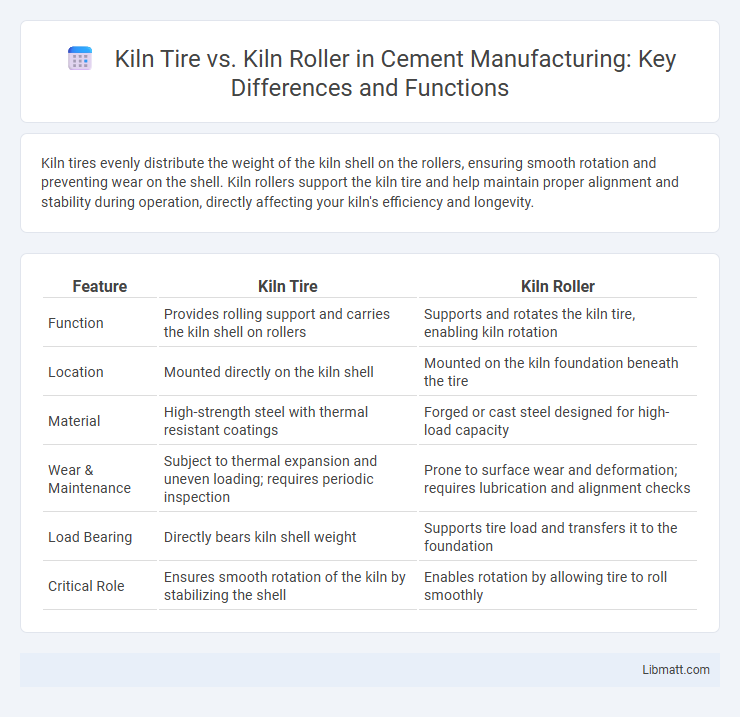

Kiln tires evenly distribute the weight of the kiln shell on the rollers, ensuring smooth rotation and preventing wear on the shell. Kiln rollers support the kiln tire and help maintain proper alignment and stability during operation, directly affecting your kiln's efficiency and longevity.

Table of Comparison

| Feature | Kiln Tire | Kiln Roller |

|---|---|---|

| Function | Provides rolling support and carries the kiln shell on rollers | Supports and rotates the kiln tire, enabling kiln rotation |

| Location | Mounted directly on the kiln shell | Mounted on the kiln foundation beneath the tire |

| Material | High-strength steel with thermal resistant coatings | Forged or cast steel designed for high-load capacity |

| Wear & Maintenance | Subject to thermal expansion and uneven loading; requires periodic inspection | Prone to surface wear and deformation; requires lubrication and alignment checks |

| Load Bearing | Directly bears kiln shell weight | Supports tire load and transfers it to the foundation |

| Critical Role | Ensures smooth rotation of the kiln by stabilizing the shell | Enables rotation by allowing tire to roll smoothly |

Introduction to Kiln Tire and Kiln Roller

Kiln tires and kiln rollers are essential components in rotary kiln operations, supporting the kiln's weight and facilitating smooth rotation. Kiln tires, large steel rings encircling the kiln shell, distribute load and control alignment, while kiln rollers bear the tire's load and enable kiln movement by rotating on shafts. Both components must withstand high temperatures and heavy mechanical forces to ensure kiln stability and operational efficiency.

Key Functions of Kiln Tires

Kiln tires are crucial for supporting and guiding the rotating kiln shell, bearing the entire weight and ensuring smooth operation. They function as large rolling rings, distributing load evenly while minimizing wear and preventing misalignment during kiln rotation. Your kiln's efficiency and longevity rely heavily on properly maintained kiln tires to reduce friction and avoid costly downtime.

Key Functions of Kiln Rollers

Kiln rollers are critical components in rotary kilns, supporting the kiln's weight and enabling smooth rotation, which ensures uniform heat distribution for efficient processing. These rollers maintain precise alignment and reduce friction between the kiln shell and support structure, directly impacting the kiln's operational stability and lifespan. Their advanced materials and design optimize load-bearing capacity and thermal resistance under high-temperature conditions.

Structural Differences: Tire vs Roller

Kiln tires are large, circular steel bands that encircle and support the rotary kiln shell, distributing load evenly and reducing wear on the kiln structure. Kiln rollers are cylindrical components mounted on bearings, supporting the kiln while allowing it to rotate smoothly under heavy loads. Understanding the structural differences between your kiln tires and rollers is crucial for maintaining optimal kiln performance and prolonging equipment life.

Material Composition and Durability

Kiln tires are typically made from ductile cast iron or alloy steel, providing exceptional strength and resistance to wear, which ensures durability under high rotational stress. Kiln rollers, often composed of forged steel with a heat-treated surface, offer enhanced toughness and fatigue resistance to support heavy loads and continuous operation. The material composition of kiln tires focuses on surface hardness and structural integrity, while kiln rollers emphasize a balance of wear resistance and mechanical flexibility to extend service life.

Installation and Maintenance Requirements

Kiln tires require precise alignment during installation to ensure even load distribution and minimize wear, while kiln rollers demand accurate positioning to support the tire and kiln shell effectively. Maintenance of kiln tires involves regular inspections for cracks, wear, and thermal stresses, whereas kiln rollers need lubrication checks, surface condition assessments, and alignment verification to prevent shaft and bearing failures. Your kiln's performance depends on balancing these installation and maintenance tasks to extend component life and avoid costly downtime.

Performance Impact on Kiln Operation

Kiln tires directly influence the rotational stability of the kiln, affecting its alignment and smooth operation, while kiln rollers bear the kiln's weight and enable its rotation, impacting mechanical efficiency and wear patterns. Poorly maintained or misaligned kiln tires lead to uneven load distribution, resulting in increased stress on kiln rollers, causing premature wear and potential operational disruptions. Optimizing the interaction between kiln tires and rollers enhances kiln throughput, reduces maintenance downtime, and improves overall kiln performance.

Common Issues and Troubleshooting

Kiln tires frequently face problems such as misalignment, wear, and flat spots, often caused by improper installation or lack of lubrication, leading to uneven rotation and increased stress on the kiln shell. Kiln rollers commonly experience bearing failures, surface wear, and misalignment due to heavy load and thermal expansion, which can result in excessive vibration and operational inefficiency. Troubleshooting these issues involves regular inspection for wear patterns, ensuring proper alignment using laser measurement tools, maintaining adequate lubrication schedules, and timely replacement of damaged components to prevent costly kiln downtime.

Cost Comparison and ROI

Kiln tires typically have a lower initial cost compared to kiln rollers, but their maintenance expenses can be higher due to frequent wear and tear. Kiln rollers, while more expensive upfront, offer longer durability and reduced downtime, leading to improved ROI over time. Choosing the right option depends onYour operational budget and long-term efficiency goals.

Choosing Between Kiln Tire and Kiln Roller

Selecting between a kiln tire and a kiln roller hinges on factors such as load capacity, heat resistance, and maintenance requirements; kiln tires provide structural support and alignment for rotary kilns, while kiln rollers facilitate smooth rotation by bearing the tire's weight. Kiln tires must withstand thermal expansion and mechanical wear, making material composition and design critical, whereas kiln rollers require precision engineering to reduce friction and evenly distribute loads. Optimal kiln operation depends on matching the tire's durability and size with rollers' load-bearing capabilities to ensure consistent performance and minimize downtime.

Kiln tire vs Kiln roller Infographic

libmatt.com

libmatt.com