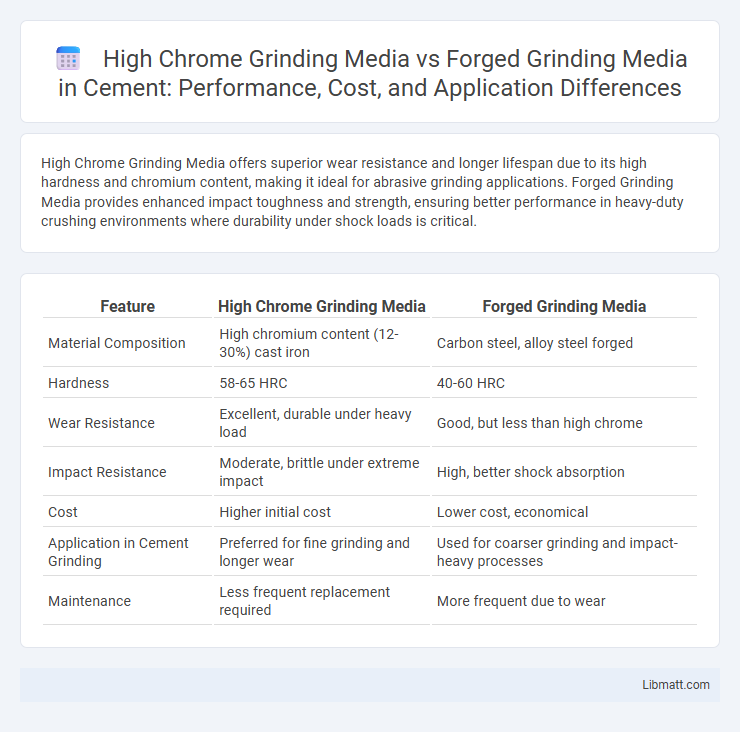

High Chrome Grinding Media offers superior wear resistance and longer lifespan due to its high hardness and chromium content, making it ideal for abrasive grinding applications. Forged Grinding Media provides enhanced impact toughness and strength, ensuring better performance in heavy-duty crushing environments where durability under shock loads is critical.

Table of Comparison

| Feature | High Chrome Grinding Media | Forged Grinding Media |

|---|---|---|

| Material Composition | High chromium content (12-30%) cast iron | Carbon steel, alloy steel forged |

| Hardness | 58-65 HRC | 40-60 HRC |

| Wear Resistance | Excellent, durable under heavy load | Good, but less than high chrome |

| Impact Resistance | Moderate, brittle under extreme impact | High, better shock absorption |

| Cost | Higher initial cost | Lower cost, economical |

| Application in Cement Grinding | Preferred for fine grinding and longer wear | Used for coarser grinding and impact-heavy processes |

| Maintenance | Less frequent replacement required | More frequent due to wear |

Introduction to Grinding Media Types

High chrome grinding media offers superior hardness and wear resistance due to its high chromium content, making it ideal for grinding abrasive materials in mining and cement industries. Forged grinding media, crafted through forging processes, provide exceptional toughness and impact resistance, suitable for handling heavy duty crushing and grinding operations. Your choice between these types depends on the specific application requirements such as abrasion levels, impact forces, and cost considerations.

Composition and Manufacturing Process

High chrome grinding media consists primarily of cast iron with chromium content ranging from 10% to 30%, produced by casting molten metal into molds, resulting in high hardness and wear resistance due to the formation of chromium carbides. Forged grinding media are made from high-carbon steel through a forging process involving heating and hammering, which enhances toughness and impact resistance by refining the grain structure. The distinct manufacturing methods influence their microstructure and mechanical properties, affecting performance in grinding applications.

Physical and Mechanical Properties Comparison

High Chrome Grinding Media offers superior hardness and wear resistance due to its high chromium content, typically ranging from 12-30%, which enhances toughness and corrosion resistance compared to Forged Grinding Media made from heat-treated alloy steel with lower hardness levels. Forged Grinding Media generally provides higher impact strength and better fatigue resistance, making it suitable for applications involving heavy impact loads and abrasive environments. Your selection should balance the need for abrasion resistance versus impact tolerance based on operational conditions, as High Chrome excels in abrasive wear and Forged Grinding Media delivers durability under shock loads.

Wear Resistance and Durability

High chrome grinding media offers superior wear resistance due to its high hardness and chromium content, making it ideal for grinding abrasive materials. Forged grinding media exhibits exceptional durability and toughness, resisting impact and reducing breakage during heavy-duty grinding operations. Wear resistance of high chrome balls reduces the frequency of replacement, while forged media's durability supports prolonged use in industrial mills, optimizing overall operational efficiency.

Performance in Various Grinding Applications

High chrome grinding media offers superior hardness and wear resistance, making it ideal for abrasive and high-impact grinding applications such as cement and mining industries. Forged grinding media provides enhanced toughness and durability, performing better in high-stress environments like cement ball mills and mineral processing. You should choose based on the specific grinding conditions, where high chrome media excels in longevity while forged media ensures resilience under impact.

Impact on Mill Efficiency

High chrome grinding media offers superior hardness and wear resistance compared to forged grinding media, resulting in longer service life and reduced media replacement frequency. The increased density and toughness of forged grinding media provide better impact energy transfer, enhancing grinding efficiency in mills. Selecting the appropriate media type depends on specific mill operating conditions and the material characteristics to optimize overall mill performance and energy utilization.

Cost Analysis: High Chrome vs Forged Media

High chrome grinding media typically offers a higher initial cost due to superior wear resistance and longer service life, reducing frequent replacement expenses. Forged grinding media generally has a lower upfront price but may incur increased maintenance and downtime costs because of faster wear rates. Evaluating your operational needs and total cost of ownership is crucial to determining the most cost-effective option for your grinding applications.

Environmental and Safety Considerations

High Chrome Grinding Media offers superior wear resistance, reducing the frequency of replacements and minimizing environmental waste compared to Forged Grinding Media. Forged Grinding Media may pose higher safety risks due to potential fractures and irregular wear patterns, increasing the chances of equipment damage and worker injury. Your choice of grinding media should consider these factors to promote safer operations and lower environmental impact.

Industry Preferences and Use Cases

High chrome grinding media is favored in mineral processing and cement industries for its exceptional wear resistance and hardness, reducing downtime and operational costs. Forged grinding media, preferred in industries requiring impact toughness such as steel and power plants, offers superior strength and resistance to breakage under heavy loads. Each type's choice depends on specific application demands, with high chrome excelling in abrasive environments and forged media ideal for high-impact conditions.

Choosing the Right Grinding Media for Your Needs

High chrome grinding media offers superior wear resistance and hardness, making it ideal for abrasive applications requiring extended life and reduced contamination. Forged grinding media provides higher toughness and impact resistance, suitable for high-impact environments where media breakage is a concern. Evaluating your specific grinding conditions and material characteristics helps you select the optimal media that balances durability, cost-efficiency, and performance for your operation.

High Chrome Grinding Media vs Forged Grinding Media Infographic

libmatt.com

libmatt.com