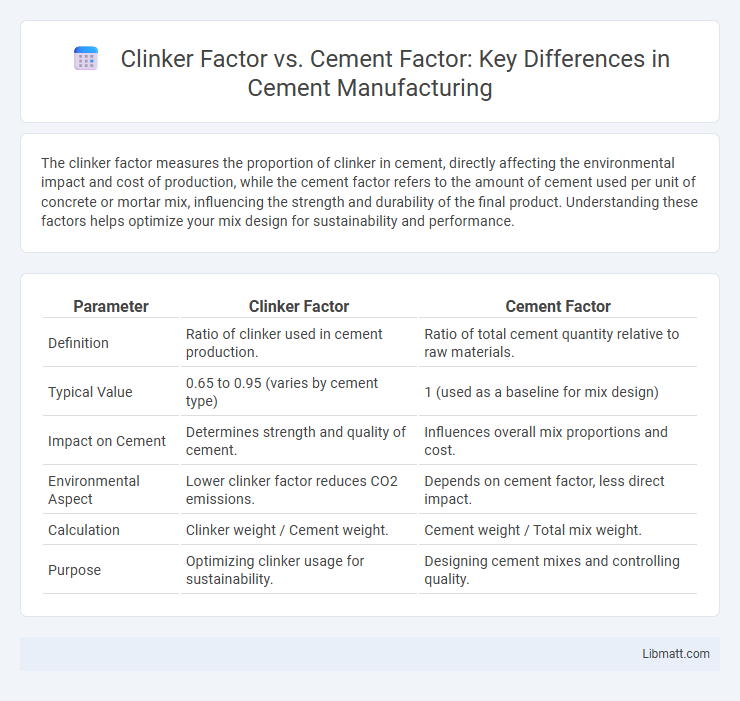

The clinker factor measures the proportion of clinker in cement, directly affecting the environmental impact and cost of production, while the cement factor refers to the amount of cement used per unit of concrete or mortar mix, influencing the strength and durability of the final product. Understanding these factors helps optimize your mix design for sustainability and performance.

Table of Comparison

| Parameter | Clinker Factor | Cement Factor |

|---|---|---|

| Definition | Ratio of clinker used in cement production. | Ratio of total cement quantity relative to raw materials. |

| Typical Value | 0.65 to 0.95 (varies by cement type) | 1 (used as a baseline for mix design) |

| Impact on Cement | Determines strength and quality of cement. | Influences overall mix proportions and cost. |

| Environmental Aspect | Lower clinker factor reduces CO2 emissions. | Depends on cement factor, less direct impact. |

| Calculation | Clinker weight / Cement weight. | Cement weight / Total mix weight. |

| Purpose | Optimizing clinker usage for sustainability. | Designing cement mixes and controlling quality. |

Understanding Clinker Factor: A Brief Overview

Clinker factor represents the proportion of clinker used in cement production relative to the total cement composition, typically expressed as a percentage. A lower clinker factor indicates increased use of supplementary cementitious materials (SCMs), which can reduce carbon emissions and production costs while maintaining cement quality. Understanding the clinker factor is essential for optimizing manufacturing efficiency and promoting sustainable construction practices.

Defining Cement Factor in Construction

Cement Factor in construction refers to the quantity of cement required per cubic meter of concrete, playing a critical role in determining concrete's strength and durability. Unlike the Clinker Factor, which pertains to the ratio of clinker in cement production impacting environmental emissions, Cement Factor directly influences the mix design and cost efficiency of your concrete projects. Accurately defining Cement Factor ensures optimal cement usage while maintaining structural quality and sustainability standards.

Key Differences Between Clinker Factor and Cement Factor

Clinker Factor represents the proportion of clinker in the total cement composition, typically expressed as a percentage, while Cement Factor denotes the total cement content used in concrete mix design per volume or weight. The clinker factor directly impacts CO2 emissions and overall energy consumption since clinker production is energy-intensive, whereas cement factor relates to the strength and durability of concrete by indicating cement quantity. Understanding the distinction is crucial for optimizing mix designs to balance environmental sustainability with mechanical performance.

Importance of Clinker Factor in Cement Production

Clinker Factor plays a crucial role in cement production by determining the proportion of clinker used relative to the total cement output, directly impacting cost efficiency and environmental footprint. Lowering the clinker factor reduces CO2 emissions and energy consumption, aligning with sustainable manufacturing practices. Understanding your clinker factor helps optimize raw material usage while maintaining cement quality and performance.

Environmental Impacts: Clinker Factor vs Cement Factor

Reducing the clinker factor lowers CO2 emissions significantly because clinker production is the most energy-intensive and carbon-intensive step in cement manufacturing. Cement factor, which refers to the total cement content in concrete, indirectly affects environmental impact; higher cement factors increase the demand for clinker, thus raising the carbon footprint. Optimizing clinker factor by blending with supplementary cementitious materials like fly ash or slag can decrease greenhouse gas emissions while maintaining concrete performance.

Optimizing Cement Formulation: Role of Clinker and Cement Factors

Clinker Factor and Cement Factor are critical parameters in optimizing cement formulation, influencing both cost efficiency and environmental impact. Clinker Factor represents the proportion of clinker in the cement, directly affecting CO2 emissions, while Cement Factor involves the total binder content adjusted for performance requirements. Understanding your project's specific needs enables precise balancing of these factors to achieve durable concrete with optimized strength, sustainability, and economy.

Economic Implications of Lowering Clinker Factor

Lowering the clinker factor reduces production costs by decreasing the amount of energy-intensive clinker used in cement, leading to significant savings on fuel and raw material expenses. This adjustment also lowers carbon emissions, aligning with sustainable construction goals while enhancing your project's environmental credentials. Optimizing the clinker factor improves economic efficiency without compromising cement quality, making it a vital strategy for cost-effective and eco-friendly cement manufacturing.

Industry Standards and Regulations for Clinker and Cement Factors

Industry standards and regulations for clinker factor and cement factor emphasize optimizing mix designs to balance performance, durability, and sustainability in concrete production. Regulatory bodies often set maximum clinker factor limits to reduce carbon emissions, encouraging the use of supplementary cementitious materials while maintaining the required concrete strength and quality. Understanding these standards ensures your concrete complies with environmental guidelines and industry specifications for construction projects.

Innovations in Reducing Clinker Content in Cement

Innovations in reducing clinker content in cement focus on incorporating supplementary cementitious materials such as fly ash, slag, and calcined clays, which contribute to lower carbon emissions and improved sustainability. Advanced grinding techniques and optimized mix designs enhance the reactivity and performance of blended cements, achieving comparable strength with reduced clinker factor. Research on novel additives and geopolymer cements further supports the transition towards eco-friendly alternatives with minimal clinker dependency.

Future Trends in Clinker and Cement Factor Optimization

The future of clinker factor and cement factor optimization emphasizes sustainable construction practices driven by advancements in alternative binders and supplementary cementitious materials (SCMs) like fly ash, slag, and calcined clays. Innovations in clinker substitution methods aim to reduce carbon emissions while maintaining concrete performance through precision mixing and real-time quality control technologies. Digitalization through AI and machine learning further enhances the optimization process by enabling data-driven adjustments to clinker and cement ratios, supporting industry decarbonization goals.

Clinker Factor vs Cement Factor Infographic

libmatt.com

libmatt.com