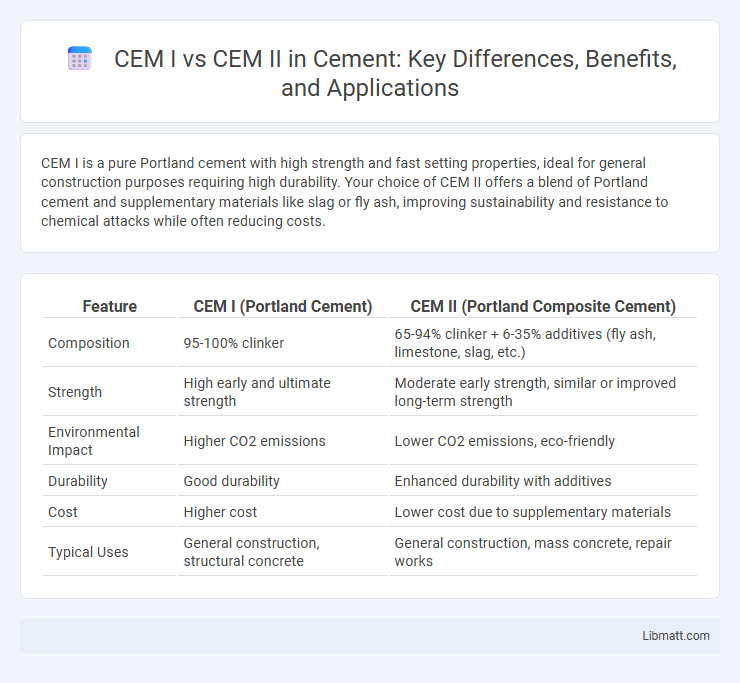

CEM I is a pure Portland cement with high strength and fast setting properties, ideal for general construction purposes requiring high durability. Your choice of CEM II offers a blend of Portland cement and supplementary materials like slag or fly ash, improving sustainability and resistance to chemical attacks while often reducing costs.

Table of Comparison

| Feature | CEM I (Portland Cement) | CEM II (Portland Composite Cement) |

|---|---|---|

| Composition | 95-100% clinker | 65-94% clinker + 6-35% additives (fly ash, limestone, slag, etc.) |

| Strength | High early and ultimate strength | Moderate early strength, similar or improved long-term strength |

| Environmental Impact | Higher CO2 emissions | Lower CO2 emissions, eco-friendly |

| Durability | Good durability | Enhanced durability with additives |

| Cost | Higher cost | Lower cost due to supplementary materials |

| Typical Uses | General construction, structural concrete | General construction, mass concrete, repair works |

Introduction to CEM I and CEM II

CEM I, also known as Ordinary Portland Cement, consists primarily of clinker and a small percentage of gypsum, delivering high early strength and durability for general construction. CEM II, or Portland-composite cement, incorporates additional materials like fly ash, slag, or limestone, improving sustainability and reducing carbon footprint while maintaining performance. Selecting between CEM I and CEM II depends on specific project requirements, with your choice influencing both environmental impact and structural characteristics.

Composition and Manufacturing Differences

CEM I cement consists primarily of clinker and a small percentage of gypsum, offering high early strength due to its nearly pure clinker content. CEM II cement is a composite where clinker is blended with supplementary materials like fly ash, slag, or limestone, enhancing durability and sustainability. Manufacturing CEM I involves solely clinker production and grinding, whereas CEM II incorporates the grinding and blending of clinker with supplementary cementitious materials, reducing carbon emissions and improving technical properties.

Chemical Properties Comparison

CEM I is primarily composed of clinker with over 95% content, resulting in higher calcium silicate phases that provide strong early strength development and faster setting times. CEM II contains 65-94% clinker with the remainder made up of additives such as fly ash, slag, or limestone, which enhance durability and reduce heat of hydration due to their slower reaction rates. Your choice between CEM I and CEM II should consider the chemical composition's impact on mechanical performance and environmental factors in construction projects.

Physical Properties and Performance

CEM I, known as ordinary Portland cement, offers high strength and rapid setting due to its high clinker content, typically around 95-100%, making it ideal for structural applications requiring quick strength gain. CEM II, or composite Portland cement, contains 65-94% clinker combined with supplementary materials like fly ash or slag, which enhance durability, reduce permeability, and improve resistance to chemical attacks, making it suitable for sustainable construction. Physical properties such as lower heat of hydration and reduced shrinkage in CEM II contribute to better long-term performance and reduced cracking risk in large-scale concrete pours.

Environmental Impact and Sustainability

CEM I, mainly composed of clinker, has a higher carbon footprint due to increased CO2 emissions during its production, whereas CEM II contains supplementary cementitious materials like fly ash or slag, reducing clinker content and lowering overall greenhouse gas emissions. The incorporation of these industrial by-products in CEM II enhances sustainability by diverting waste from landfills and decreasing energy consumption during manufacturing. Consequently, CEM II contributes significantly to environmental impact reduction and aligns better with sustainable construction practices.

Typical Applications of CEM I

CEM I, also known as Portland cement, is predominantly used in structural concrete for buildings, bridges, and infrastructures due to its high strength and durability. Its rapid setting properties make it ideal for applications requiring quick strength gain, such as precast concrete and concrete repairs. You will find CEM I widely applied where high-performance concrete is essential, especially in load-bearing and heavy-duty construction projects.

Typical Applications of CEM II

CEM II cement, also known as Portland-composite cement, is commonly used in general construction projects such as residential buildings, pavements, and precast concrete elements due to its improved durability and reduced clinker content compared to CEM I. It provides better sulfate resistance and lower heat of hydration, making it suitable for massive structures and environments with moderate exposure to aggressive conditions. Typical applications include bridges, tunnels, and foundations where enhanced performance and sustainability are prioritized.

Cost Implications and Market Availability

CEM I cement, known for its high clinker content, typically costs more due to energy-intensive production but offers superior early strength, affecting initial project budgets. CEM II cement contains supplementary materials like fly ash or slag, reducing production costs and increasing market availability due to the use of industrial by-products. Your choice between CEM I and CEM II impacts both construction expenses and sourcing options, with CEM II often preferred for cost efficiency and sustainability.

Standards and Regulatory Requirements

CEM I and CEM II are defined under the EN 197-1 standard for common cements in Europe, where CEM I is 95-100% clinker and CEM II incorporates 65-94% clinker with supplementary cementitious materials like fly ash or slag. Regulatory requirements mandate CEM I for applications demanding high early strength and durability, while CEM II meets standards for sustainable construction by reducing clinker content and CO2 emissions. Performance criteria specified in EN 197-1 ensure both types comply with mechanical strength classes and chemical composition limits for safe and reliable construction use.

Choosing the Right Cement: CEM I vs CEM II

CEM I cement consists of at least 95% clinker, offering high early strength and durability ideal for structural concrete and demanding construction applications. CEM II cement incorporates additional components like limestone or slag, reducing CO2 emissions and improving workability while maintaining adequate strength for general building purposes. Selecting between CEM I and CEM II depends on project-specific requirements such as strength, environmental impact, and cost-efficiency.

CEM I vs CEM II Infographic

libmatt.com

libmatt.com